الدليل الشامل لتوصيل الكابلات: أنواع التصميم والأحجام واللوائح وأفضل الممارسات

1. Introduction to Cable Trunking Systems

Cable trunking is an essential component of electrical installations, designed to house and protect cables while ensuring an organized and efficient wiring system. It consists of enclosed channels, typically made from materials such as PVC, steel, or aluminum, that prevent damage from environmental factors and mechanical stress.

A well-designed cable trunking system must account for material durability, cable load capacity, installation requirements, and compliance with industry standards. By incorporating these considerations, cable trunking ensures safety, efficiency, and longevity in electrical infrastructure.

In this post, we will explore the key aspects of cable trunking, including its types, materials, sizes, regulations, certifications, and best practices for installation. We hope this guide provides valuable insights and helps you implement effective cable management solutions.

2. Exploring the Different Types of Cable Trunking

2.1 Based on Material

Cable trunking systems can be made from a variety of materials, each with unique properties that make them suitable for specific environments or applications.

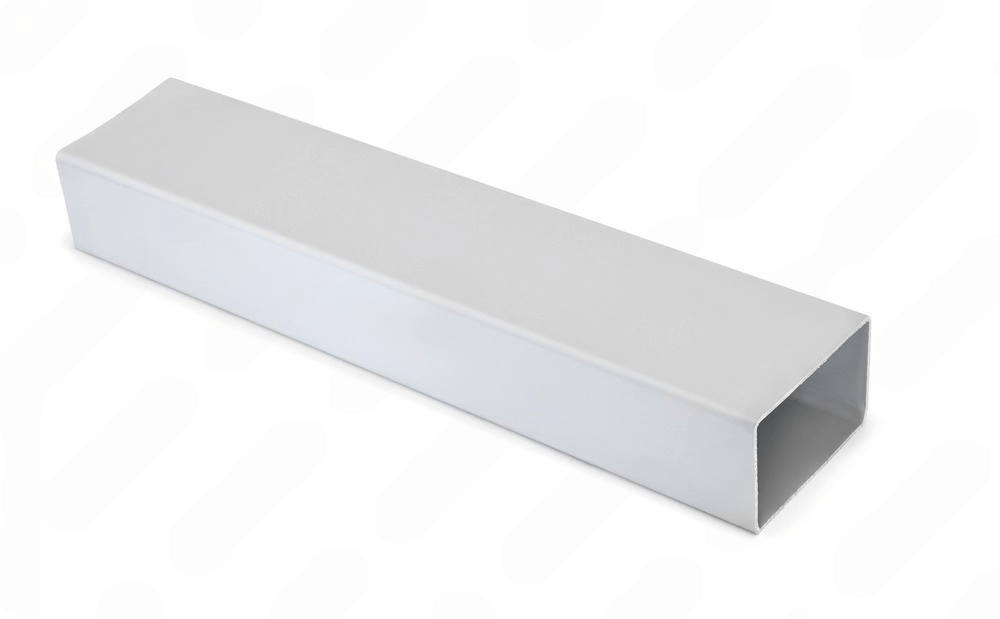

2.1.1 PVC (Polyvinyl Chloride) Cable Trunking

PVC is one of the most commonly used materials for cable trunking due to its versatility, cost-effectiveness, and ease of installation. It offers several advantages:

Durability: PVC is resistant to corrosion, making it suitable for use in harsh environments where exposure to chemicals, moisture, or UV rays is common.

Lightweight: PVC trunking is easy to handle and install, reducing labor costs during installation.

Electrical Insulation: As a non-conductive material, PVC provides excellent electrical insulation, reducing the risk of electrical accidents.

However, PVC cable trunking may not be suitable for high-temperature environments, as it can soften and deform under heat.

2.1.2 Steel and Metal Cable Trunking

Steel and metal cable trunking systems are commonly used in applications where durability and resistance to physical damage are essential. They offer a number of key benefits:

Strength and Protection: Metal trunking is highly durable and resistant to mechanical damage, making it ideal for industrial or high-traffic environments.

Fire Resistance: Metal does not burn, which provides added protection in the event of a fire.

EMI Shielding: Steel and metal trunking systems provide shielding against electromagnetic interference (EMI), which is important in sensitive areas like data centers and laboratories.

However, metal trunking tends to be more expensive than PVC, and it can be heavier, making installation more challenging.

2.1.3 Aluminum Cable Trunking

Aluminum is another popular choice for cable trunking, offering a balance between weight and durability. Aluminum trunking systems provide several key benefits:

Lightweight: Aluminum is much lighter than steel, making it easier to handle and install.

Corrosion Resistance: Aluminum is highly resistant to corrosion, particularly in environments where the trunking may be exposed to moisture or chemicals.

Aesthetic Appeal: Aluminum trunking often has a cleaner, more aesthetically pleasing appearance compared to steel, making it suitable for office buildings or visible installations.

However, aluminum may not be as strong as steel in high-impact situations, and it may require additional protection in areas with high mechanical stress.

2.2 Based on Application

Cable trunking systems can be categorized based on their installation environment and intended function. Different applications require specific designs to ensure optimal cable protection, accessibility, and safety. The three main types of application-based cable trunking are floor trunking, wall-mounted trunking, and overhead/industrial trunking.

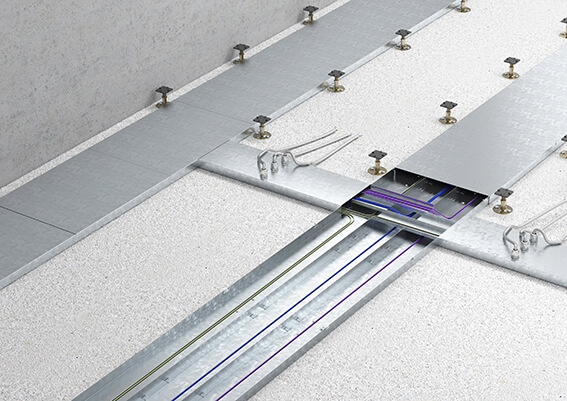

2.2.1 Floor Trunking

Floor trunking is designed for installations where cables need to run beneath flooring surfaces, ensuring both protection and a clutter-free environment. This type of trunking is commonly used in commercial offices, conference rooms, data centers, and retail spaces where multiple power, data, and communication cables must be routed efficiently without creating trip hazards.

2.2.2 Wall-Mounted Trunking

Wall-mounted trunking is one of the most commonly used cable management solutions, designed to run along walls and vertical surfaces to keep wiring organized and protected. It is widely applied in residential, commercial, and industrial settings, ensuring easy access while maintaining a neat and professional appearance.

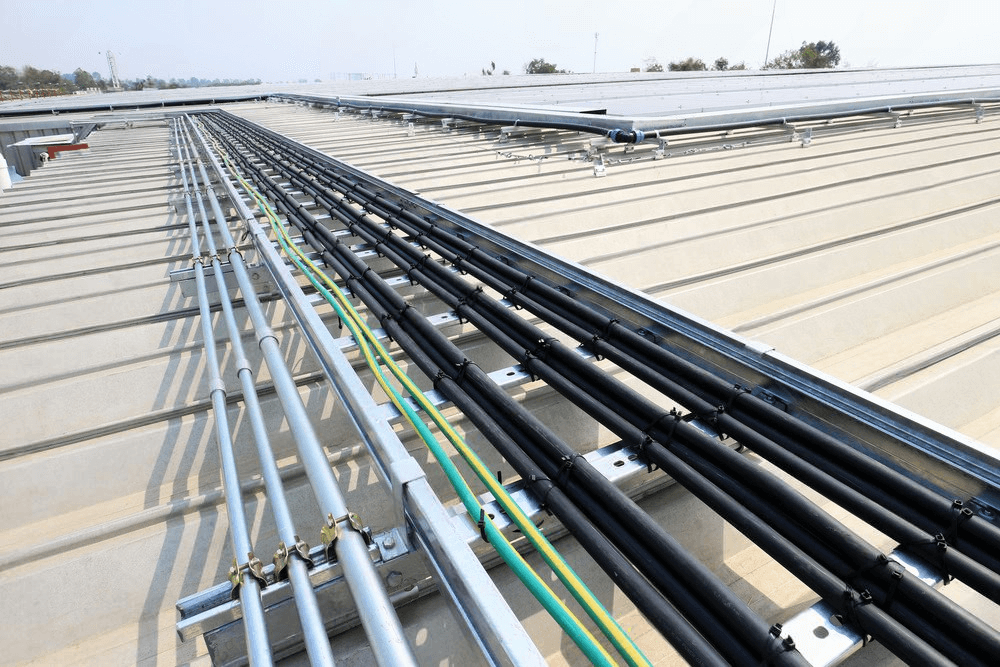

2.2.3 Overhead/Industrial Trunking

Overhead or industrial trunking is designed for environments where cables need to be routed above ground, typically along ceilings or overhead beams. This type of trunking is especially common in factories, warehouses, industrial plants, and large commercial buildings. It provides an efficient solution for managing cables in spaces where floor or wall installations may not be feasible due to space constraints or other operational factors.

2.3 Based on Structure

Cable trunking systems can also be classified based on their internal structure, which influences how cables are organized, protected, and accessed. The structural design of a trunking system determines its suitability for specific applications, the type of cable it can house, and how it facilitates future modifications. The main structural categories include single compartment, multi-compartment, perforated, and slotted or solid trunking systems.

2.3.1 Single Compartment

Single compartment trunking is the most straightforward design, offering a single enclosed space for routing and protecting cables. This type of trunking is ideal for applications where a limited number of cables are needed, and there is no immediate need to separate different cable types (e.g., power, data, and communication cables).

2.3.2 Multi-Compartment Trunking

Multi-compartment trunking is designed with several internal sections or dividers, allowing for the separation of different types of cables, such as power cables, data cables, and communication lines. This design is particularly useful in environments where it is essential to maintain organization and reduce the risk of interference between different cable types.

2.3.3 Perforated Trunking

Perforated trunking features small holes or slots along the sides of the trunking, allowing for better airflow and easy cable entry. This type of trunking is ideal for environments where ventilation and heat dissipation are crucial, such as in data centers or areas with high-density cable installations. The perforations also facilitate cable management, making it easier to add or remove cables without needing to open the trunking completely.

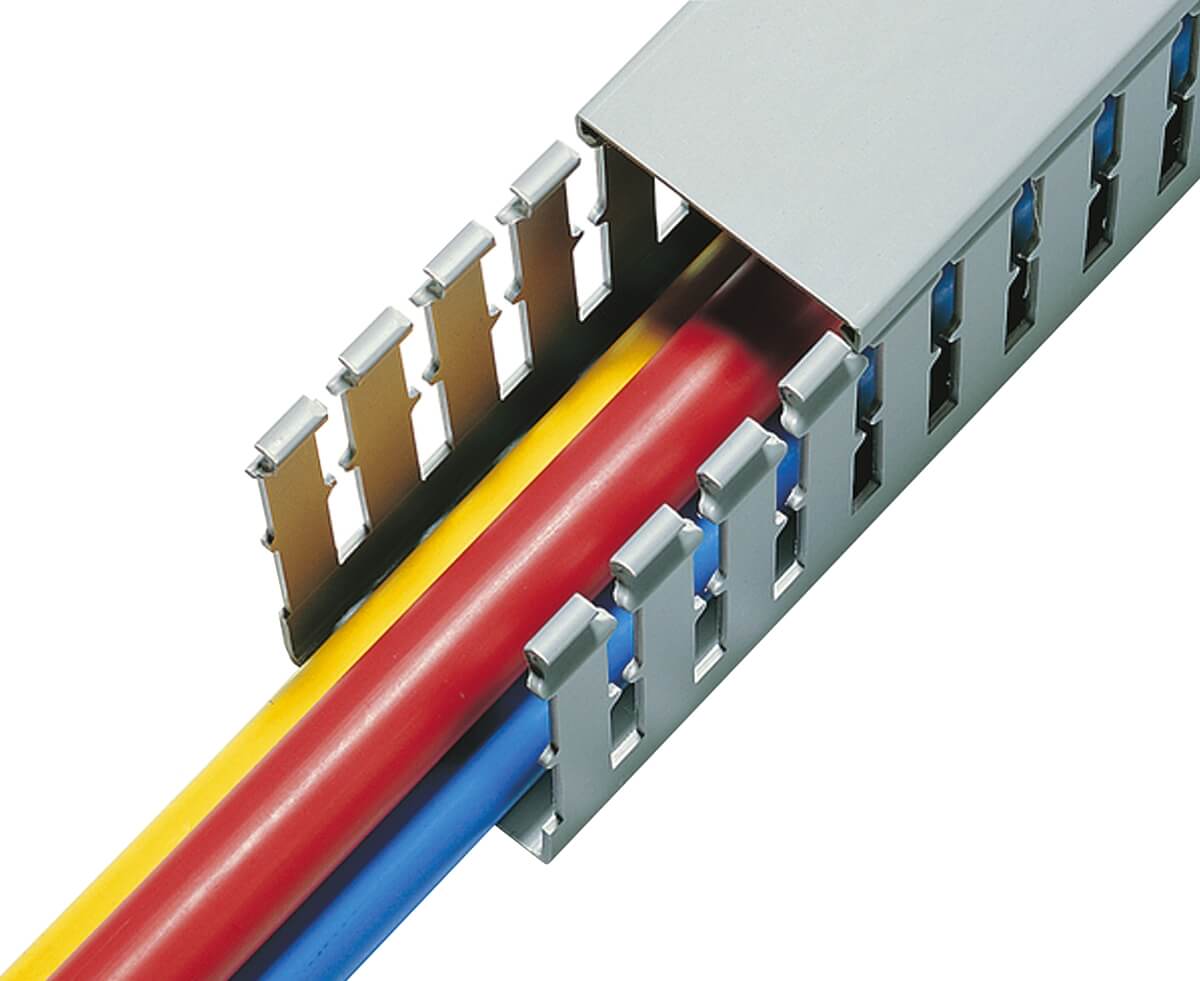

2.3.4 Solid vs Slotted Trunking

Solid and slotted trunking refer to two different structural configurations of cable management systems.

Solid trunking offers a completely enclosed space for cables, providing a high level of protection against dust, dirt, moisture, and physical damage.

The slotted design allows for quick access to cables, making it easier to add, remove, or modify cables without disassembling the entire system.

3. Cable Trunking Sizes and Dimensions

Selecting the correct size and dimensions for cable trunking is critical to ensuring that cables are adequately protected, organized, and easy to maintain. The size of the trunking system affects its ability to house multiple cables, allow for future expansions, and manage heat dissipation. In this section, we will explore the factors influencing the size of cable trunking, standard sizing conventions, and how to choose the right dimensions for different applications.

3.1 Factors Influencing Cable Trunking Size

Number and Type of Cables – The number and type of cables that need to be routed through the trunking will influence its size. For example, high-density systems like those in data centers will require larger trunking to accommodate numerous cables.

Cable Dimensions – The diameter of the cables being used is another important consideration. Larger cables or those with thicker insulation may require more space within the trunking to prevent damage and ensure proper ventilation.

Future Expansion – Planning for future expansions is critical when selecting trunking size. Trunking that is too small may lead to overcrowding, while selecting a larger size than needed can be cost-inefficient.

Ventilation Requirements – Certain applications, particularly in high-power environments, require trunking that allows for sufficient airflow to dissipate heat. This may affect the size and type of trunking selected.

3.2 Standard Cable Trunking Sizes

Cable trunking comes in a range of sizes, with standard dimensions often specified by international standards. The size of trunking is typically defined by its width, height, and internal compartment size.

Width – The width of the trunking refers to the horizontal space available for cables. It is essential to ensure that the width is sufficient to house the required number of cables while maintaining a manageable arrangement.

Common widths: 25mm, 50mm, 75mm, 100mm, 150mm, 200mm, etc.

Height – The height of the trunking is important for organizing cables in a vertical direction. Taller trunking can accommodate more cables and allow for better separation of cable types.

Common heights: 25mm, 50mm, 75mm, 100mm, 150mm, etc.

Depth – The depth is often considered alongside width and height, as it affects the available space for cables. It is typically available in shallow or deep options.

Common depths: 25mm, 50mm, 75mm, 100mm, etc.

Internal Compartments – Multi-compartment trunking will have internal dividers, which can vary in size depending on the number of cables and their specific type. These dividers ensure the trunking is optimized for organized and safe cable routing.

3.3 How to Choose the Right Size of Cable Trunking

Calculate the Total Number of Cables – Begin by calculating the total number of cables you will need to route. Consider all power, data, and communication cables, and estimate their total diameter when grouped together.

Measure Cable Dimensions – Measure the diameter of the cables to be used, including any insulation or protective sheathing. This will help determine the minimum required width and depth of the trunking.

Allow for Extra Space – Add extra space (typically 20-30%) to the total cross-sectional area of the cables to allow for flexibility, easy installation, and future additions to the system.

Account for Heat Dissipation – Ensure the trunking size allows adequate airflow for cooling, particularly in environments where cables may carry high currents or are grouped together in a dense configuration.

Consider Cable Separation – If you are using multi-compartment trunking, ensure the individual compartments are wide enough to separate cables without causing overcrowding.

3.4 Cable Trunking Size for Specific Applications

Different environments and applications require different trunking sizes. Below are examples of typical size requirements for various settings:

Residential and Small Commercial Installations – For low-density cable systems such as lighting and basic power distribution, smaller trunking sizes, such as 25mm x 50mm or 50mm x 75mm, are often sufficient.

Office Buildings and Data Centers – In environments where a significant number of power and data cables need to be routed together, larger trunking sizes such as 100mm x 100mm or 150mm x 150mm may be required.

Industrial Applications – Heavy-duty environments with complex machinery, high-voltage cables, or high-density wiring may need trunking sizes like 200mm x 200mm or even larger, depending on the complexity of the system.

4. Cable Trunking Regulations and Standards

Understanding the regulations and standards that govern the use of cable trunking is essential to ensure safety, compliance, and optimal performance in electrical installations.

4.1 International Standards for Cable Trunking

There are several international standards that provide guidelines for the construction, testing, and installation of cable trunking systems. These standards help ensure that the trunking systems are safe, reliable, and suitable for various applications.

IEC 61084 – This standard, developed by the International Electrotechnical Commission (IEC), defines the requirements for cable trunking systems used in electrical installations. It covers the dimensions, materials, mechanical properties, and performance characteristics of cable trunking, as well as fire resistance and load-bearing capacity.

BS EN 50085 – This European standard specifies the performance characteristics of cable trunking systems, focusing on dimensions, strength, and resistance to environmental conditions such as heat, moisture, and chemicals. It also addresses the necessary features to ensure that trunking is safe and effective for use in electrical installations.

4.2 National Regulations for Cable Trunking Installation

Different countries have their own regulations regarding the installation of cable systems. As one of the cable protection types, cable trunking installation should follow the national or local regulations.

National Electrical Code (NEC) – In the United States, the NEC governs the installation of electrical systems. The NEC outlines the requirements for conduit systems, cable protection, and accessibility for future modifications.

BS 7671 (IET Wiring Regulations) – In the UK, the IET Wiring Regulations (often referred to as BS 7671) provide comprehensive rules for electrical installations.

AS/NZS 3000 – In Australia and New Zealand, the AS/NZS 3000 standard is widely used for electrical installations, ensuring that the system is properly installed to minimize the risk of electrical hazards.

4.3 Certifications for Cable Trunking Systems

To ensure that cable trunking systems meet safety, environmental, and performance standards, they must be certified by recognized organizations.

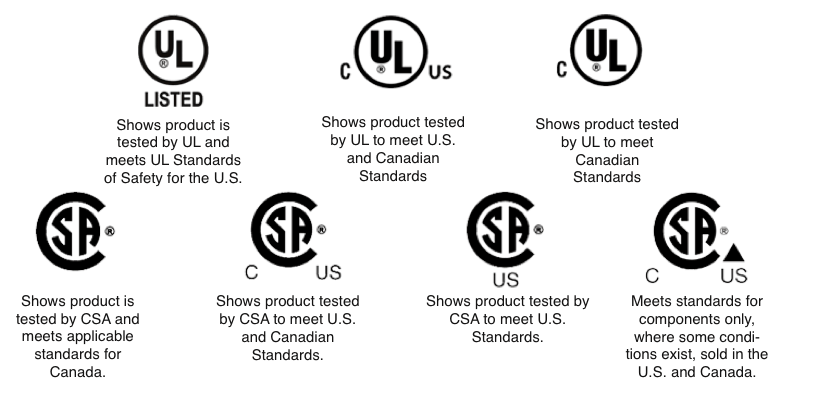

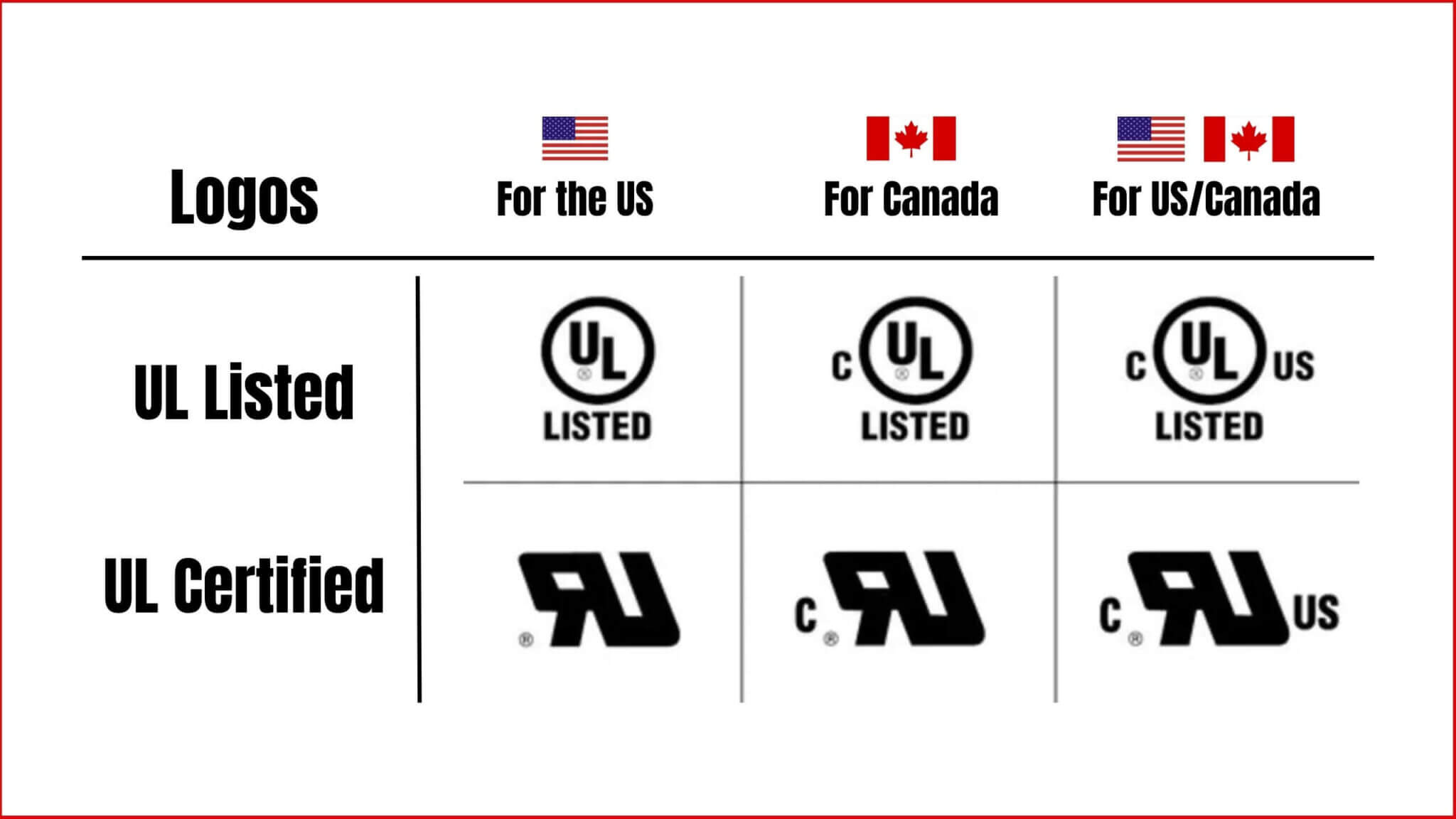

4.3.1 UL (Underwriters Laboratories) Certification

In the United States, UL certification is a key indicator that a cable trunking system meets safety and performance standards. UL tests the materials for fire resistance, mechanical durability, and electrical insulation properties.

4.3.2 CE Marking

The CE mark is required for products sold in the European Economic Area (EEA). It indicates that the cable trunking system complies with European Union (EU) regulations on safety, health, and environmental protection. CE marking is essential for ensuring that the product meets the necessary requirements for use in Europe.

4.3.3 IEC Certification

The International Electrotechnical Commission (IEC) sets global standards for electrical equipment. Key IEC standards include IEC 61084 for cable trunking systems, which covers design, dimensions, and mechanical performance.

4.3.4 RoHS Compliance

The RoHS (Restriction of Hazardous Substances) directive restricts the use of certain hazardous substances in electrical and electronic equipment.

4.3.5 ISO Certification

ISO certifications, such as ISO 9001 for quality management systems, demonstrate that the manufacturer adheres to international standards for product quality, consistency, and continuous improvement.

5. How to choose Cable Trunking

5.1 Key Factors in Choosing Cable Trunking

5.1.1 Material Selection Based on Performance Needs

Different materials offer varying levels of durability, protection, and environmental resistance. When choosing cable trunking, consider the following material properties.

Durability: Heavy-duty applications, such as industrial settings, require impact-resistant materials like steel or reinforced PVC.

Corrosion Resistance: For humid or chemical-exposed areas, aluminum or PVC trunking provides better resistance compared to standard metal options.

Fire Resistance: Environments requiring fire protection, such as commercial buildings and transport hubs, should use fire-rated trunking to minimize fire hazards.

UV and Weather Resistance: Outdoor installations should use UV-resistant PVC or powder-coated aluminum trunking to withstand prolonged sun exposure and harsh weather conditions.

5.1.2 Choosing the Right Trunking for Different Applications

The intended installation environment plays a key role in selecting the appropriate cable trunking system.

Indoor Applications: Offices, retail spaces, and commercial buildings benefit from PVC trunking due to its lightweight structure, easy installation, and cost-effectiveness.

Outdoor Applications: For external environments, weather-resistant metal or UV-stabilized PVC trunking is preferred to ensure long-term durability.

High-Temperature and Chemical Exposure Areas: Industrial facilities, chemical plants, and factories require fire-rated metal trunking or chemical-resistant PVC to ensure long-term reliability under extreme conditions.

5.2 Structural and Functional Considerations

Accessibility & Maintenance: If frequent access to cables is required, opt for removable-lid trunking or multi-compartment systems to separate and organize different circuits.

Aesthetic & Space Constraints: In visible areas, slimline PVC trunking provides a clean, discreet installation, while floor trunking helps prevent trip hazards in high-traffic spaces.

Cable Volume & Load Capacity: High-density wiring setups require multi-compartment or perforated trunking to improve organization and airflow.

5.3 Compliance and Safety Requirements

Always ensure the selected cable trunking meets industry regulations we mentioned above.

6. Comparison: Cable Trunking vs Other Cable Management Systems

6.1 Cable Tray vs. Cable Trunking

6.1.1 Structural Differences

Cable Trunking: A partially or fully enclosed pathway designed to organize and shield cables from dust, moisture, and physical impact. It often includes a removable cover for easy access.

Cable Tray: An open, ladder-like or perforated structure that supports cables while allowing maximum airflow and heat dissipation.

6.1.2 Performance Considerations

Protection: Trunking offers varying degrees of protection depending on its design. Fully enclosed trunking provides better shielding, while slotted or ventilated trunking offers moderate protection. Cable trays, being open, provide minimal direct protection but prevent overheating.

Accessibility: Trunking allows modifications by removing the cover, while cable trays enable direct access without disassembly.

6.1.3 Best Applications

Cable trunking is ideal for commercial buildings, offices, and structured electrical systems where organization and moderate protection are priorities.

Cable trays are commonly used in industrial environments, large-scale facilities, and areas with high heat dissipation needs.

6.2 Conduit vs. Cable Trunking

6.2.1 Design and Installation

Cable Trunking: A structured, often rectangular pathway that can be fully enclosed, ventilated, or slotted for easier cable access and organization.

Conduit: A tubular, rigid or flexible system that completely encloses individual or bundled cables, providing enhanced environmental protection.

6.2.2 Durability and Protection

Trunking provides moderate protection against dust, mechanical impact, and accidental contact but is less effective against moisture and extreme conditions.

Conduit, particularly rigid metal or heavy-duty PVC variants, offers superior resistance to water, fire, chemicals, and mechanical damage.

6.2.3 Best Applications

Cable trunking is commonly used in indoor environments where accessibility and organization are key, such as offices, control panels, and commercial settings.

Conduit is essential for harsh environments, including outdoor, underground, and industrial applications where cables require maximum protection.

7. الخاتمة

Wire protection is essential for ensuring the safety, longevity, and efficiency of electrical systems. Choosing the right material for a project—whether it’s cable trunking, conduit, or other protective solutions—is key to preventing hazards and maintaining smooth electrical operation. The best material is one that meets the specific needs of the installation environment, providing durability, fire resistance, and compliance with industry standards.

We hope this guide has provided valuable insights into cable trunking and helped you make informed decisions about cable management solutions.

في كتوب, we specialize in manufacturing high-quality electrical conduits designed for various applications, including residential, commercial, and industrial projects. Our products are built to meet strict safety and performance standards, offering reliable protection against environmental and mechanical factors.

Thanks for your reading and good luck with your projects.

الدليل الشامل لتوصيل الكابلات: أنواع التصميم والأحجام واللوائح وأفضل الممارسات اقرأ أكثر "