Top 10 Electrical Conduit Pipe Suppliers in Singapore

1. Cantex

Company Values and Vision

Cantex Inc. is a distinguished name in the electrical conduit industry, recognized for its unwavering commitment to quality and customer satisfaction. The company’s core values revolve around integrity, innovation, and sustainability. Cantex prioritizes maintaining high standards of performance and reliability in its products while fostering a culture of continuous improvement. Their vision is to lead the industry through excellence in manufacturing and a deep understanding of customer needs, ensuring that every product not only meets but exceeds expectations.

Product Range: Electrical Conduits and Fittings

Cantex offers an extensive selection of electrical conduit and fitting solutions designed to cater to various application needs:

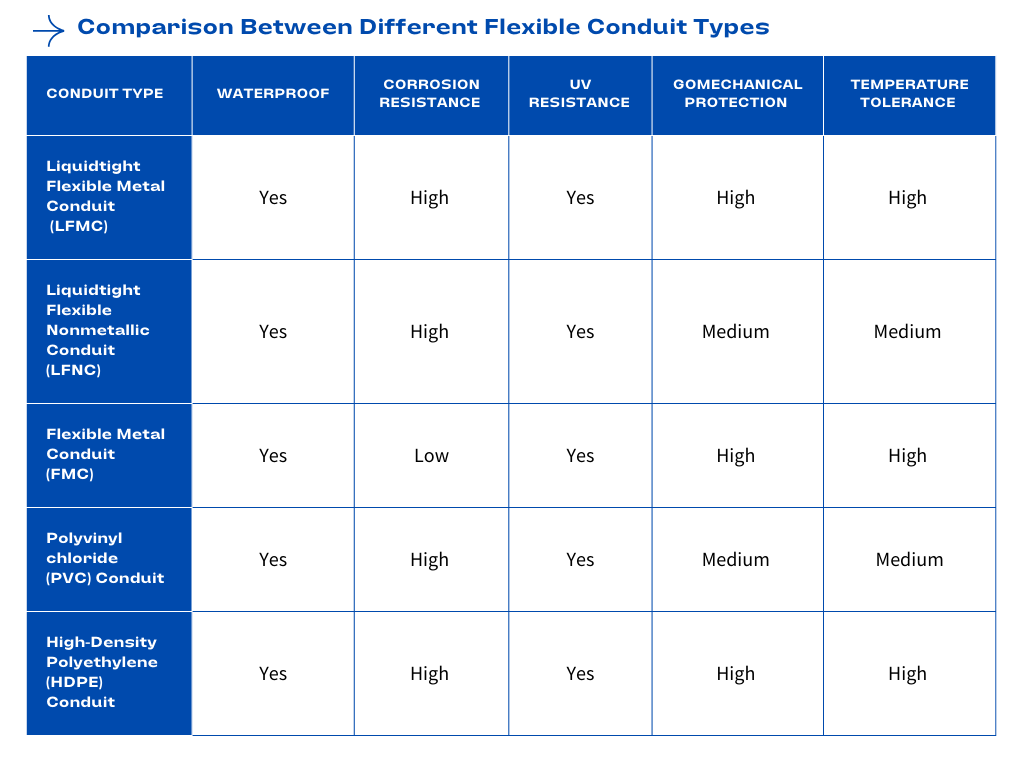

- PVC Conduit: Cantex’s PVC conduit is renowned for its durability, corrosion resistance, and versatility. It is available in both standard and heavy-duty options, making it suitable for a wide range of residential and commercial installations.

- Fittings and Accessories: The company provides a diverse array of fittings, including couplings, elbows, and connectors. These components are engineered for secure and reliable connections, ensuring a robust and long-lasting installation.

- Specialty Products: In addition to standard offerings, Cantex features specialty products such as flexible conduit and specialized conduit systems. These are tailored to meet specific requirements, including high-temperature applications and environments subject to heavy mechanical stress.

2. Ipex

Company Values and Vision

With over 80 years of industry experience, Iplex has established itself as a prominent provider of conduit solutions, focusing on delivering high-quality products and services. The company’s core values of safety, innovation, and customer collaboration drive its commitment to addressing industry challenges and offering effective solutions. Iplex’s vision is to lead the market with sustainable and innovative products, ensuring that their solutions meet current needs and anticipate future demands.

Product Range: Electrical and Telecommunications Conduits

Iplex offers a comprehensive range of conduits designed for various applications in the electrical and telecommunications sectors:

- PVC-U Conduits: Iplex’s PVC-U conduits are designed to protect cables in both buried and above-ground installations. PVC-U is widely used due to its lightweight properties, ease of assembly, and non-conductivity. These conduits are suitable for safeguarding both fiber optic and telecommunication cables.

- Comprehensive Delivery Options: To optimize project management, Iplex provides conduit pipes, electrical pits, and accessories as a complete package. This approach offers time and cost savings for project managers and contractors by simplifying procurement and installation processes.

- Polyethylene (PE100) Conduits: For applications involving trenchless or direct burial installations, Iplex supplies polyethylene conduits available in coils or large drums. PE100 conduits are known for their durability and flexibility, making them suitable for demanding underground environments.

3. Atkore

Company Values and Expertise

Atkore is a global leader in electrical solutions, renowned for its extensive experience and innovation in the industry. With a century of expertise, Atkore is dedicated to providing high-quality products that power and protect critical infrastructure. The company is committed to delivering comprehensive solutions that ensure electricity flows safely, efficiently, and effectively across various applications. Atkore’s dedication to customer satisfaction and operational excellence solidifies its reputation as a trusted and preferred supplier worldwide.

Comprehensive Product Range

Atkore offers a broad portfolio of electrical products designed to meet diverse needs across various sectors:

- Conduit Solutions: Atkore provides a wide selection of conduits, including steel, PVC, and aluminum, as well as PVC-coated options. These conduits are engineered to protect electrical wiring in different environments, ensuring durability and reliability.

- Armored and Flexible Cables: The company’s armored cables offer enhanced protection for challenging conditions, while flexible conduits are ideal for dynamic installations requiring adaptability.

- Support Systems: Essential components such as strut systems, wire baskets, and cable trays are available to support and organize electrical infrastructure, contributing to efficient project execution.

4. Electri-Flex

Company Values and Legacy

For 65 years, Electri-Flex has been a trailblazer in the electrical industry, renowned for its innovation, quality, and value-added solutions in flexible conduit, wire, and cable protection. The company’s commitment to excellence is reflected in its dedicated workforce and industry-leading manufacturer representatives. Electri-Flex’s strong legacy is built on a foundation of superior craftsmanship and a forward-looking approach, ensuring its continued success in the 21st century and beyond.

Comprehensive Product Range

Electri-Flex offers an extensive array of flexible electrical conduits, catering to various needs and applications:

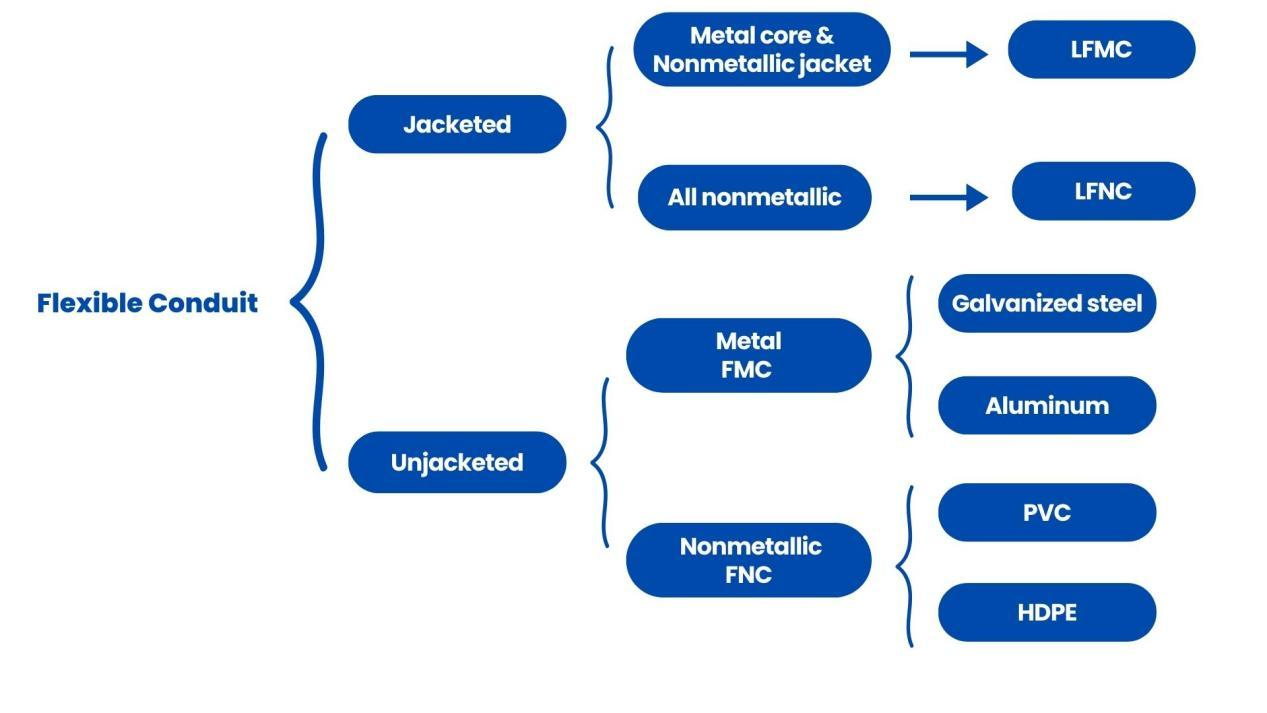

- Unjacketed/Jacketed Metallic Conduit: Known for its flexibility and strength, ideal for various environments without an outer jacket. And also provides robust protection with an additional layer of jacket material for enhanced durability and resistance to environmental factors.

- EMI/RFI Shield-Flex®: Offers three levels of shielding effectiveness to protect sensitive electronic circuits from electromagnetic and radio frequency interference. Available with halogen-free jacketing for added safety.

- Nonmetallic Conduit: Lightweight and corrosion-resistant, made from flexible and rigid PVC, suitable for corrosive environments and weight-sensitive applications.

- Stainless Steel Conduit: Provides exceptional durability and resistance to corrosion, suitable for harsh or high-temperature environments.

- Specialized Conduit: Their halogen-free conduits are designed to minimize toxic smoke in the event of a fire. Antimicrobial conduits are also available, incorporating properties that prevent microbial growth, making them ideal for hygienic environments. Corrosion-resistant conduits are built to withstand corrosive elements, ensuring long-term performance and reliability. Additionally, Electri-Flex provides low and high temperature conduits that remain flexible in cold environments and resist aging in high temperatures. These options are available in both nonmetallic and jacketed metallic varieties.

5. Bahra Electric

Company Overview and Values

Founded in 2008 as Bahra Cables, Bahra Electric has rapidly emerged as a key player in the electrical industry. Initially focused on wires and cables, the company quickly rose to become the 48th largest wire and cable manufacturer globally in just eight years. This achievement reflects Bahra Electric’s dedication to innovation, quality, and customer satisfaction. As part of its growth strategy, Bahra Electric has diversified its offerings, now producing a wide range of complementary electrical products, expanding to 11 main product lines that meet the critical needs of customers in various sectors.

Product Offering and Commitment to Quality

- Conduit Solutions: Bahra Electric manufactures a range of conduits, including Extra Heavy Duty, Heavy Duty, Medium Duty, and Light Duty options. These conduits comply with international standards (NEMA, IEC, SASO) and are designed to provide reliable protection for electrical wiring in various applications.

- Couplings and Adapters: The company offers a variety of coupling options, including standard, expansion, and telescoping double tube expansion couplings. Bahra Electric also provides male and female adapters, ensuring compatibility and flexibility in installation.

- Boxes and Bends: Bahra Electric produces a wide selection of electrical boxes, such as loop-in, terminal, and angle boxes, as well as heavy-duty bends with bell ends or couplings. These products ensure safe and effective routing of electrical conduits.

- Saddles and Accessories: The product range includes strap saddles and saddles with bases, along with essential accessories like circular lids, extension rings, adaptable boxes, bending springs, and PVC solvent cement for smooth installations.

6. ANAMET Electrical, Inc.

Company Overview and Values

Founded in 1908, ANAMET Electrical, Inc. has established itself as a global leader in the manufacture of flexible, liquid-tight conduit systems. Originally known for its expertise in durable conduit solutions, the company has expanded its product offerings to meet the evolving needs of various industries. ANAMET Electrical is renowned for its commitment to innovation, quality, and customer satisfaction, with a strong emphasis on adhering to stringent safety and performance standards.

Product Offering and Commitment to Quality

- Conduit Solutions: ANAMET Electrical provides a comprehensive range of conduit systems, including the ANACONDA SEALTITE® series. These products are designed to protect electrical wiring and cables in harsh environments, offering solutions for outdoor, underground, and confined space installations. The conduit options include types for extreme temperatures, corrosive conditions, and special applications such as zero halogen and anti-static environments.

- Flexible Metallic Conduit: The company’s flexible metallic conduits are available in both UL listed and non-listed varieties. These conduits are constructed from various metals, including aluminum and galvanized steel, providing flexibility and resistance to corrosion and crush. They are suitable for commercial, industrial, and OEM applications.

- Non-Metallic Conduit: ANAMET offers non-metallic options that are CSA certified and RoHS compliant. These conduits are ideal for applications requiring flexibility, corrosion resistance, and continuous flexing. Products include liquid-tight, non-conductive conduits with various reinforcing materials.

- Specialty Conduit: The company’s specialty conduit range includes solutions for high-level shielding, radiation resistance, and extreme temperatures. This includes conduits designed for use in nuclear containment areas, high-temperature environments, and food-grade applications.

- Fittings and Accessories: ANAMET Electrical’s product lineup also features a broad selection of fittings and accessories. This includes metallic and plastic fittings for secure connections, as well as high-performance accessories like fixture whips, cord grips, and fire protection materials.

7. Steel Tube Institute

Company Overview and Values

The Steel Tube Institute (STI) serves as a vital resource and leader in the steel tube and conduit industry. With a focus on advancing manufacturing techniques and promoting the benefits of steel products, STI collaborates with top industry members to provide innovative solutions for various sectors. Their mission is rooted in delivering high-quality steel tubing products while educating specifiers, designers, and builders on the unmatched utility and versatility of steel in modern applications.

Product Offering and Commitment to Quality

The Steel Tube Institute is recognized for its high standards and diverse product offerings in steel conduit and tubing. STI’s steel conduit products are integral to its mission, reflecting the company’s dedication to delivering reliable, resilient, and sustainable solutions for electrical systems.

- Rigid Metal Conduit (RMC): Manufactured to deliver maximum durability, RMC is an essential product for environments requiring the highest level of mechanical protection. STI’s RMC is built to withstand severe physical impacts and environmental stress, making it ideal for industrial and outdoor applications. The product’s strength reflects STI’s commitment to producing raceways that safeguard electrical conductors in the most demanding conditions.

- Intermediate Metal Conduit (IMC): IMC from STI combines strength with lightweight properties, offering a flexible solution that balances protection and ease of installation. IMC is perfect for projects that require robust protection but benefit from a lighter, more manageable conduit option, aligning with STI’s mission of providing versatile solutions for a broad range of projects.

- Electrical Metallic Tubing (EMT): Known for its ease of use and cost-effectiveness, STI’s EMT is a go-to product for residential and commercial applications. EMT offers reliable protection for electrical wiring in spaces that don’t require the heavy-duty strength of RMC or IMC, yet still demand high-quality performance. The lightweight and bendable nature of EMT exemplifies STI’s focus on providing flexible, efficient, and reliable solutions.

8. Whitehouse Flexible Tubing Ltd

Company Overview and Values

Whitehouse Flexible Tubing Ltd is a family-owned business with a long and proud history that dates back to the late 1800s when George Whitehouse established a brass foundry in Birmingham. Over the years, the company evolved and adapted to market demands, transitioning from manufacturing brass products like bedsteads and door handles to focusing on flexible tubing solutions for various industrial applications. Guided by four generations of family leadership, the company has continued its commitment to innovation, customer satisfaction, and quality. Today, Whitehouse Flexible Tubing Ltd remains at the forefront of flexible tubing manufacturing, with a dedication to providing reliable solutions to customers across different industries.

Product Offering and Commitment to Quality

- Flexible Metal Conduits: Whitehouse Flexible Tubing Ltd produces a diverse range of flexible metallic conduits, including PVC-covered, galvanized, and stainless steel options. These conduits are ideal for the protection of electrical cables in construction and industrial applications. The Galvanized Steel PVC Covered Conduit provides excellent protection with its low smoke & fume (LSF) PVC coating, making it suitable for general-purpose applications, while the Stainless Steel Uncovered Conduit offers enhanced temperature resistance for demanding environments.

- Fittings and Accessories: The company also manufactures a variety of high-quality fittings to complement its conduit products. These include the Swivel Conduit Fitting, a two-piece brass nickel-plated fitting designed for ease of installation, and the Fixed Male Conduit Fitting, which offers a secure, durable connection. Whitehouse also provides Plain Hole Fittings, ideal for seamless installations in a variety of environments.

9. Champion Fiberglass

Company Overview and Values

Founded with a vision to revolutionize conduit solutions, Champion Fiberglass has become a leading name in the industry, known for its innovation and commitment to excellence. The company specializes in producing high-quality fiberglass conduit (RTRC), a material increasingly favored for its lightweight yet durable properties.

Champion Fiberglass is dedicated to sustainability and efficiency, reflecting in its state-of-the-art manufacturing processes that optimize performance while reducing costs. By focusing on innovation and customer satisfaction, the company supports engineers and industry professionals in achieving their project goals with confidence.

Product Offering and Commitment to Quality

- Champion Fiberglass delivers a diverse range of high-quality products engineered to enhance performance and durability in various applications

- Champion Duct: Offers robust and flexible fiberglass ducting solutions designed to provide reliable protection and performance for electrical systems, even in demanding environments.

- Champion Fiberglass Elbows: Precision-engineered elbows that facilitate smooth and efficient directional changes in conduit systems, ensuring seamless installation and operational efficiency.

- Champion Flame Shield Phenolic Conduit: Delivers exceptional fire resistance for applications requiring enhanced safety and protection against fire hazards.

- Champion Haz Duct XW Type: Specialized ducting for hazardous environments, providing superior protection and ensuring compliance with stringent safety standards.

- Champion Utility & Pole Risers: Durable risers designed for utility and pole applications, ensuring secure and reliable connections under various environmental conditions.

10. Ctube

Company Overview and Values

Ctube, a premier PVC conduit and fittings manufacturer based in China, is renowned for its commitment to providing high-quality solutions for cable management and protection. Established with a focus on innovation and excellence, Ctube has earned a reputation as a trusted partner in the electrical conduit industry by continually investing in advanced manufacturing technologies and maintaining a customer-centric approach. The company’s dedication to advanced manufacturing processes and rigorous quality control ensures that its products consistently meet the highest standards of performance and reliability, driving its position as a leader in the field.

Product Offering and Commitment to Quality

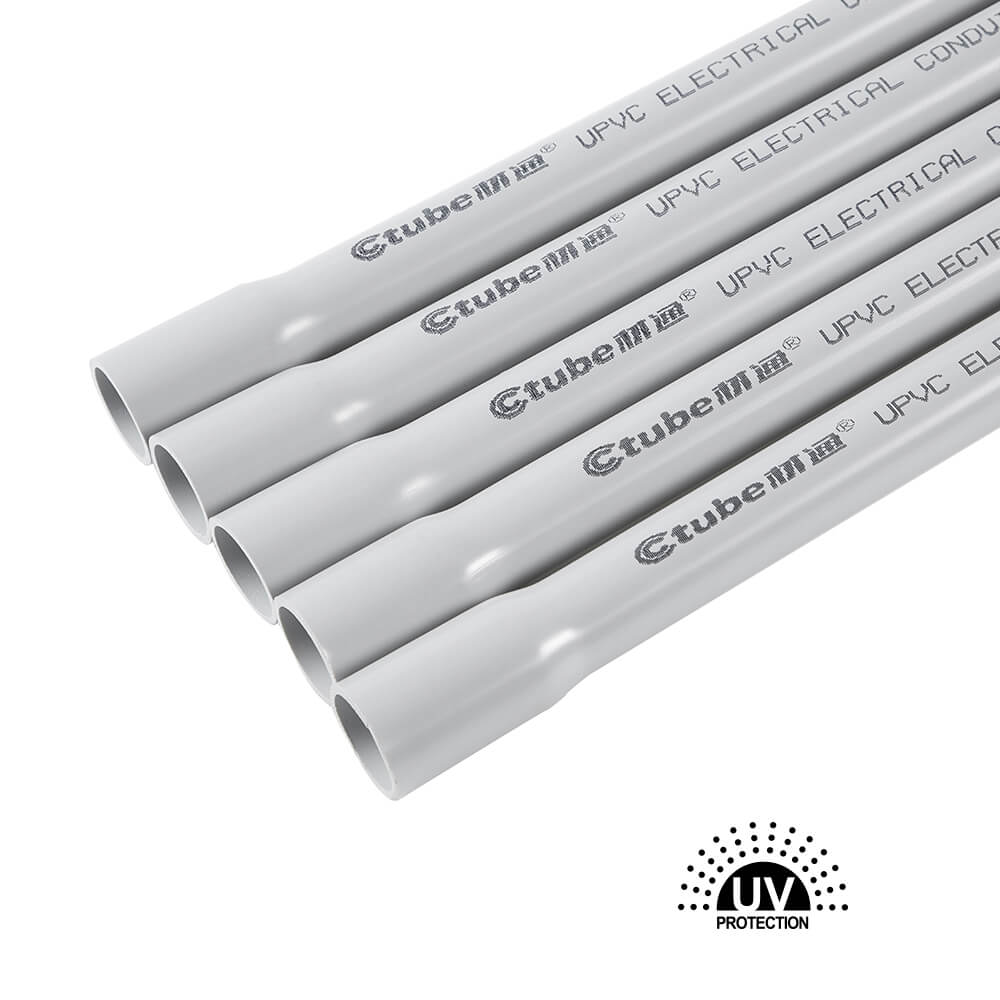

Ctube’s extensive product range is known for its durability, flexibility, and superior protection for electrical wiring, ensuring long-lasting and efficient performance in diverse applications. The lineup includes:

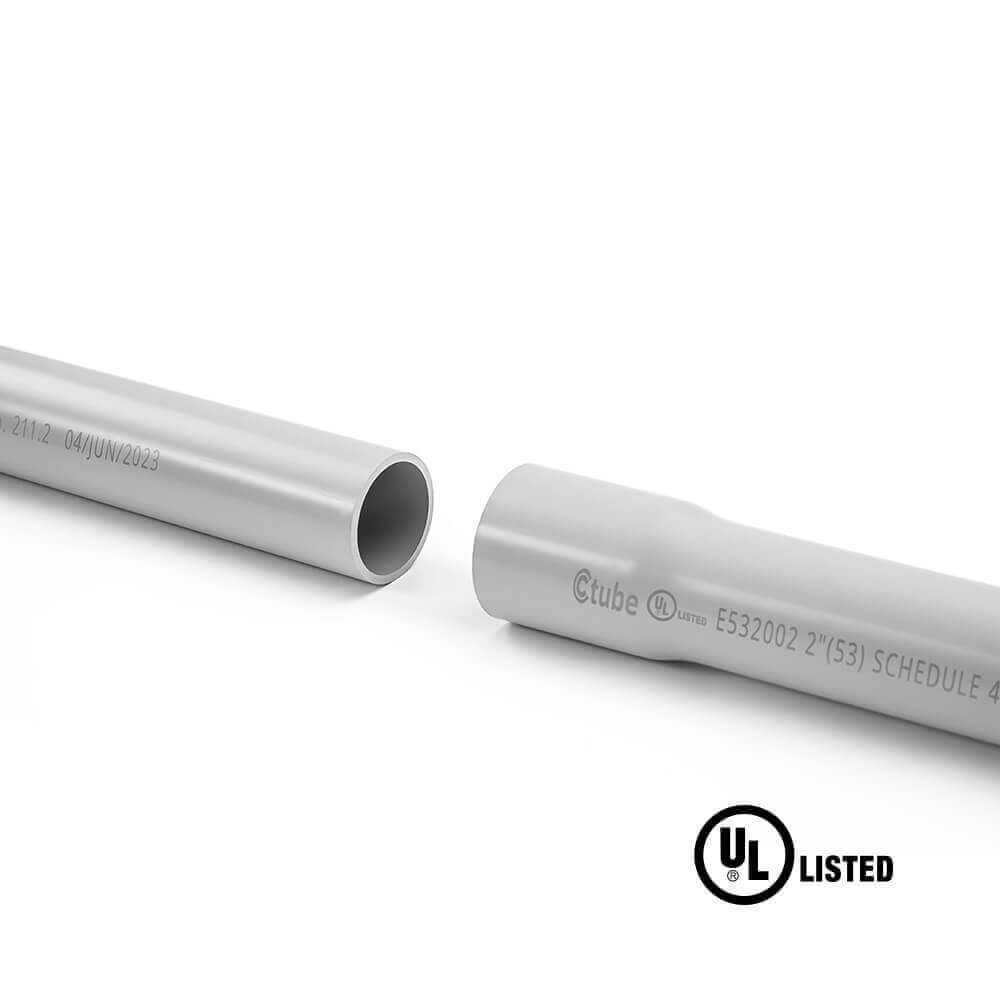

- PVC Rigid Conduit and Electrical Nonmetallic Tubing (ENT): Designed for versatile and reliable cable management across various applications, these products offer excellent resistance to impact, chemicals, and environmental factors, making them suitable for both residential and industrial settings.

- Conduit Fittings: A comprehensive selection of fittings, including couplings, adaptable boxes, and male adapters, ensuring seamless connections and system integrity. These fittings are engineered to provide secure and reliable junctions, preventing issues such as leaks and disconnections.

- Low Smoke Halogen Free Conduits: Specially engineered to emit minimal smoke and no toxic gases during a fire, enhancing safety in critical environments such as hospitals, schools, and commercial buildings. This ensures that emergency situations are managed more effectively, minimizing risks to life and property.

- Photovoltaic Solar Conduits: Built to withstand extreme outdoor conditions with exceptional UV resistance, these conduits are crucial for solar power systems, including the world’s largest solar project, the Abu Dhabi Al Dhafra PV2 Solar Power Project. Their robust design supports long-term performance and reliability in harsh environmental conditions.

Product complies with the AS/NZS 2053 Standard, UL listings, and CSA certification, reflecting Ctube’s adherence to the highest quality and safety standards. This commitment not only ensures the reliability and durability of their products but also reinforces Ctube’s dedication to meeting global industry benchmarks and customer expectations.

Top 10 Electrical Conduit Pipe Suppliers in Singapore Read More »