5 Benefits of Using PVC Electrical Conduit in Your Next Project

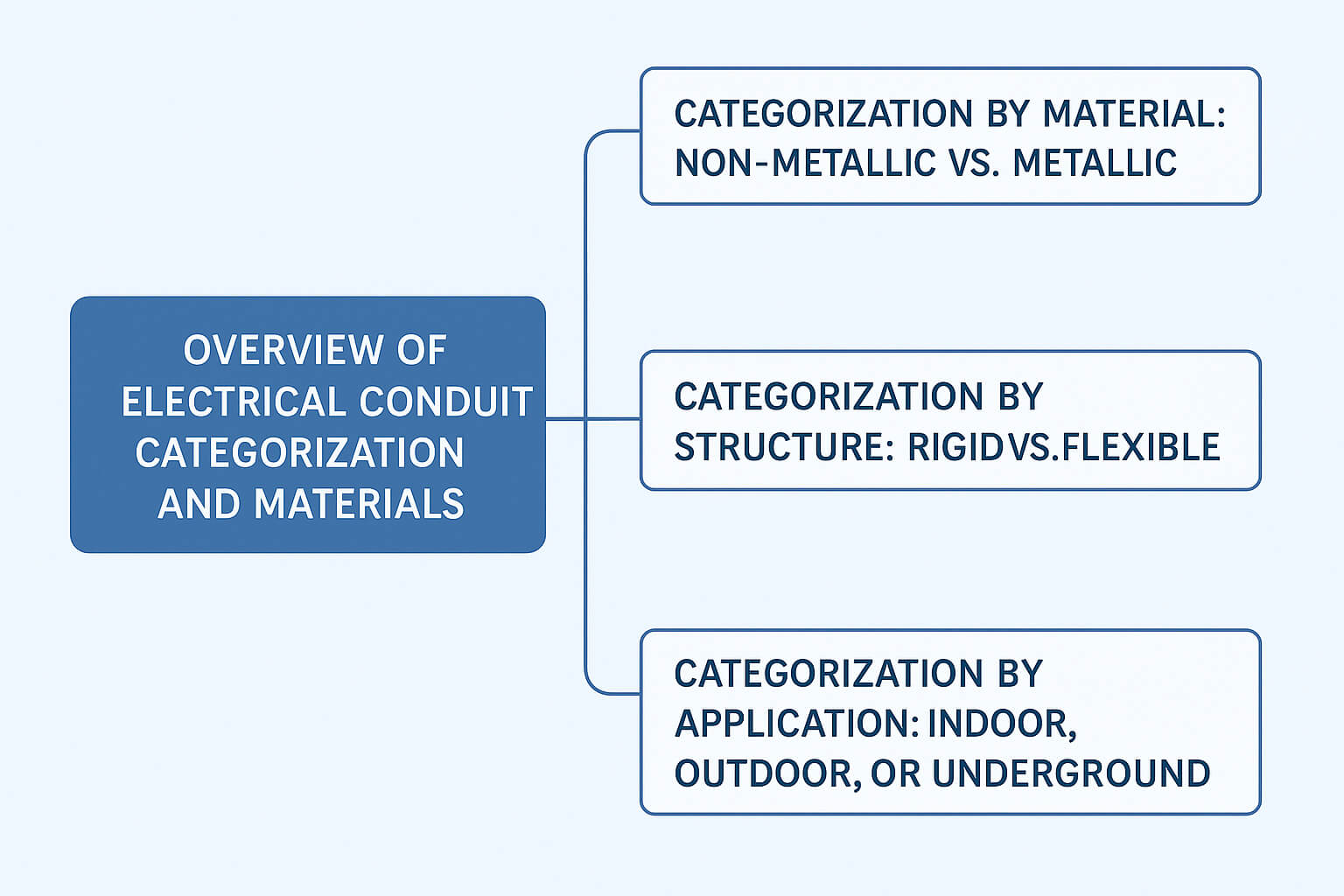

1. Introduction to Electrical Conduit Pipe

In modern electrical installations, choosing the right conduit material is a critical decision that impacts safety, longevity, and overall project cost.

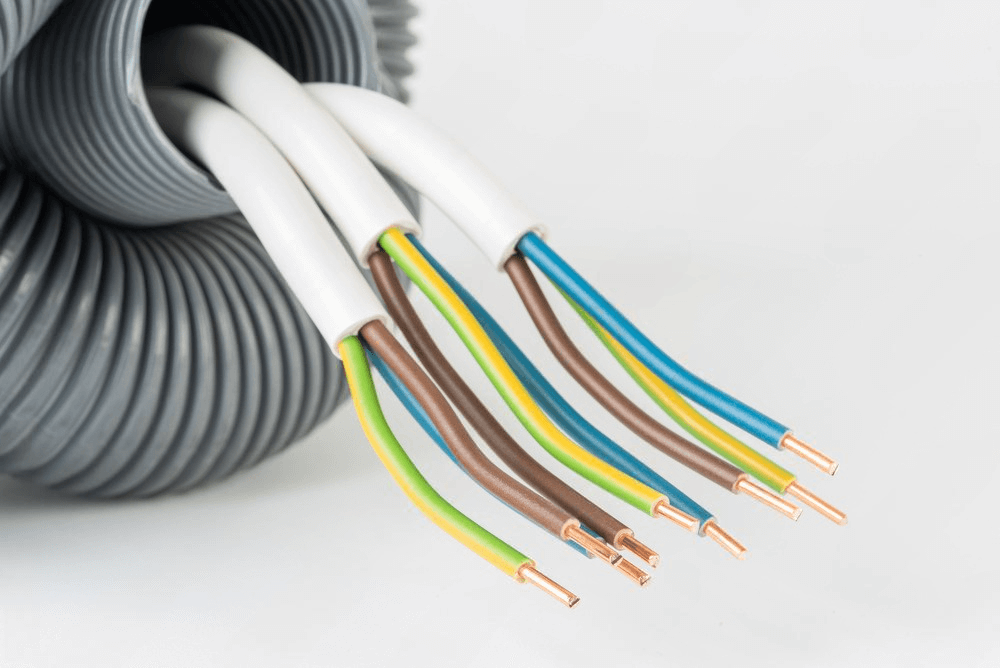

Whether you’re planning to pull wire through conduit in a commercial setting, run electrical wire underground, or install a wall wire conduit system for residential applications, selecting the appropriate material ensures smoother installation and long-term reliability.

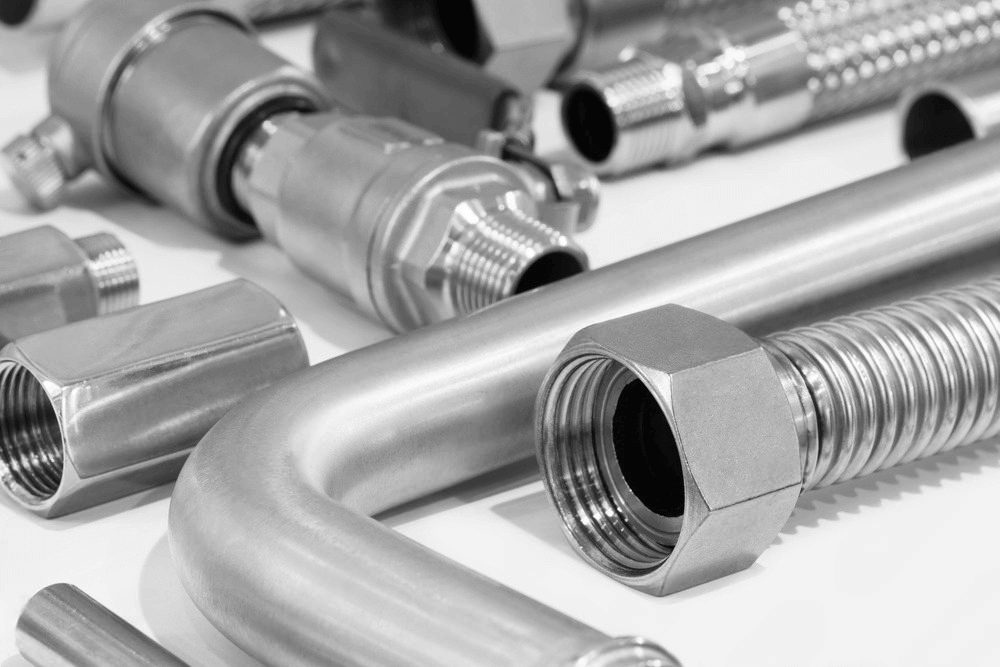

From metal conduit known for EMI shielding to HDPE conduit used in directional boring, and RTRC conduit for heavy-duty corrosion resistance, each option offers unique features.

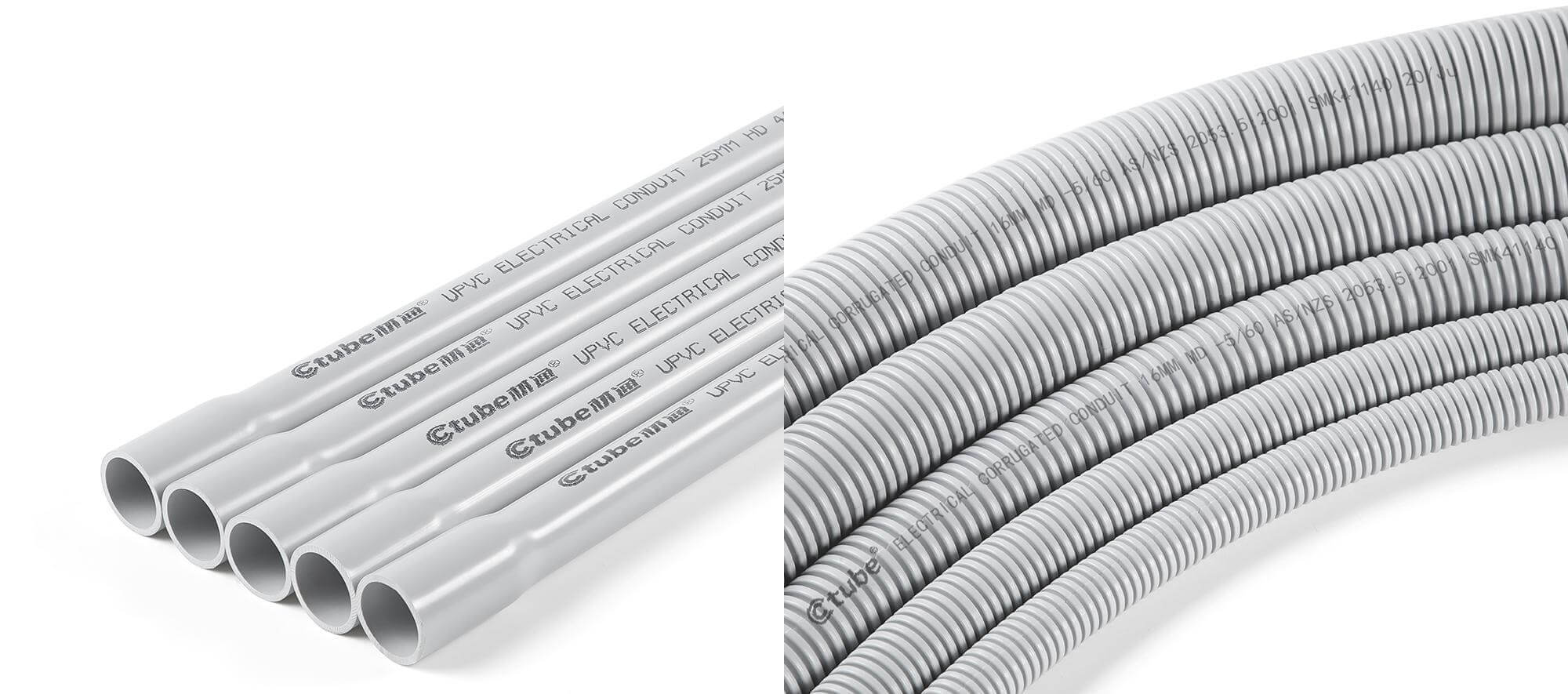

However, PVC electrical conduit—available in both rigid and flexible types—continues to be a leading choice for many professionals due to its ease of use and cost efficiency.

This post is tailored for electrical contractors, engineers, and construction professionals looking to streamline installation, hide wires effectively, and maintain compliance with electrical codes.

We’ll explore the top five benefits of using PVC conduit, including real-world comparisons and applications such as running wire through conduit systems for walls, ceilings, or underground use.

2. Corrosion Resistance of PVC Electric Conduit

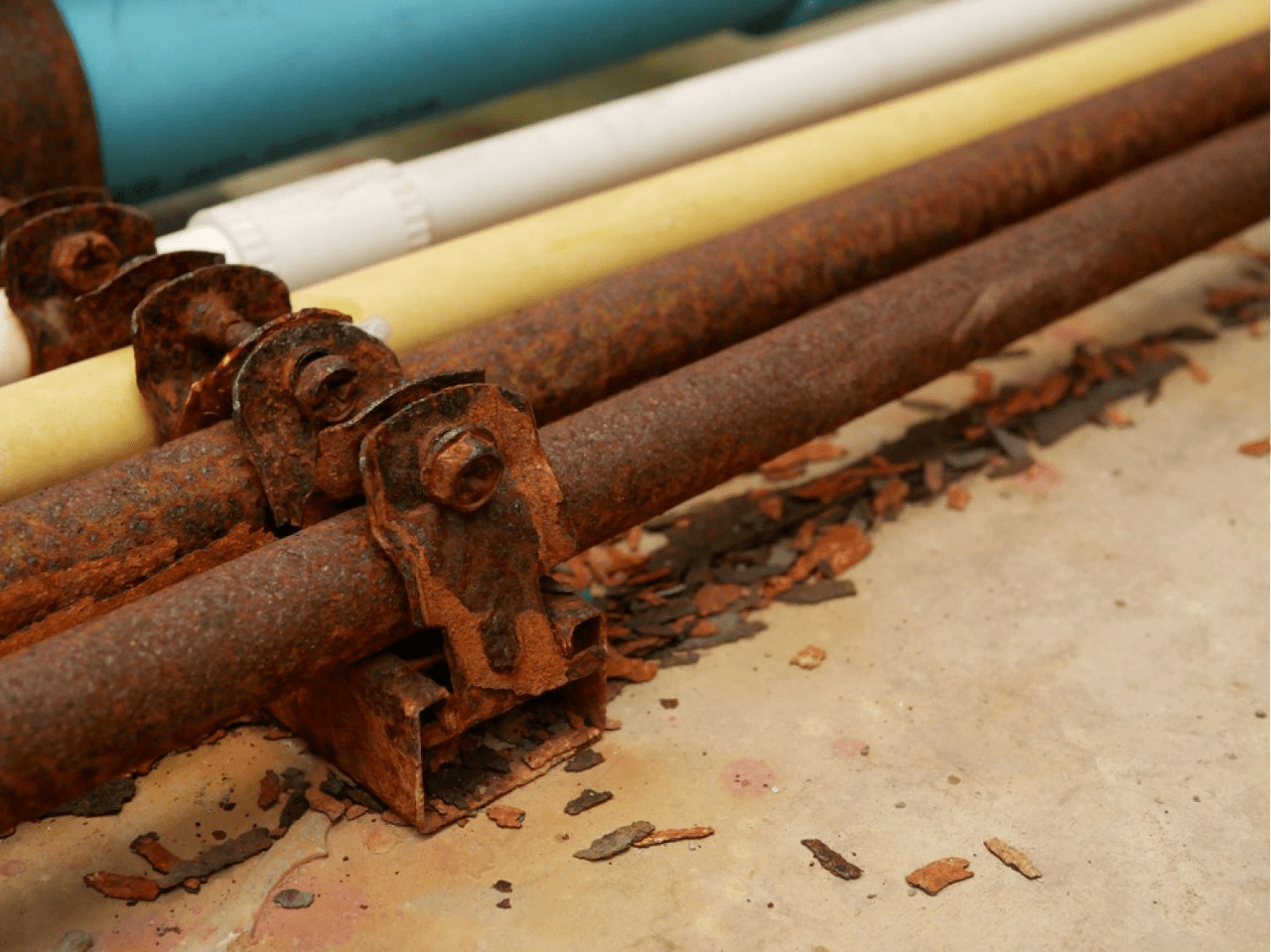

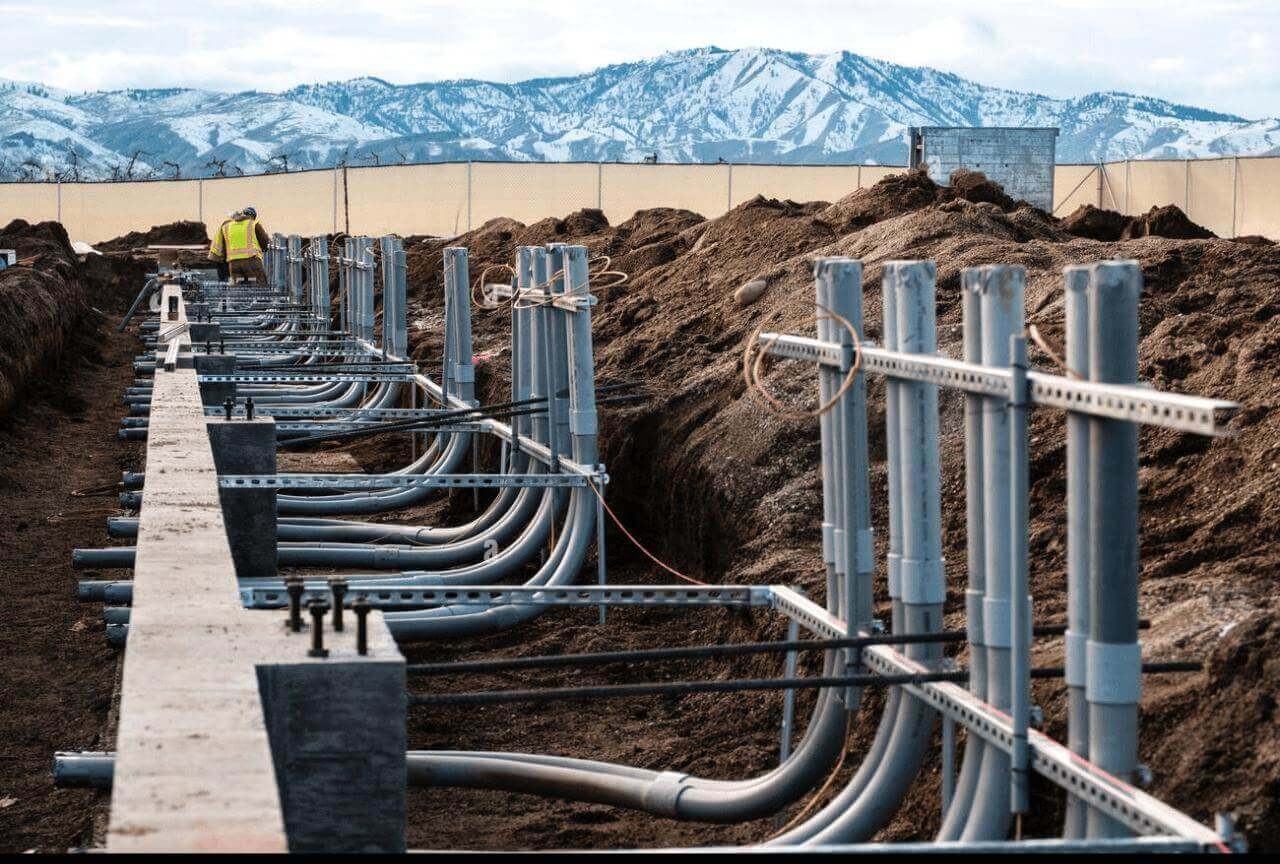

When it comes to installing PVC conduit outside or burying conduit underground, corrosion resistance becomes a top priority.

Unlike metal pipe conduit or metal wire conduit, which are prone to rust when exposed to moisture, chemicals, or acidic soil, PVC underground electrical conduit is non-metallic and naturally immune to corrosion—making it an ideal solution for wet or buried environments.

This rustproof characteristic is especially important in regions with high ground moisture, where pvc conduit bury depth often exceeds 18 inches to meet safety requirements.

According to the NEC code for buried conduit, the buried electrical conduit must maintain structural integrity and protection from physical damage.

- Under residential driveways, NEC buried conduit depth typically requires at least 18 inches.

- For buried electrical conduit under concrete or inside structures, the conduit bury depth can be as shallow as 6–12 inches, provided additional mechanical protection is used.

In comparison, systems using electrical metal conduit may require coatings or seals to prevent corrosion.

Even liquidtight flexible metal conduit, while offering water resistance, can degrade over time in underground or humid conditions—and it tends to be more expensive due to its complex structure and material costs.

By contrast, PVC electrical conduit serves as a waterproof conduit solution by default, offering reliable protection without the need for external treatments—and at a significantly lower cost, making it a more budget-friendly choice for many installations.

It’s also worth noting that other non-metallic options like High-density polyethylene conduit and fiberglass conduit offer similar resistance to rust.

However, PVC stands out for its balance of corrosion resistance, affordability, and ease of installation—making it a contractor favorite when running wire inside conduit systems underground or through exterior walls.

Whether you’re pulling wire inside conduit across a damp basement, setting up a wall wire conduit exposed to rain, or complying with NEC buried conduit depth in outdoor applications, PVC conduit delivers long-term protection without the risk of corrosion-related failures.

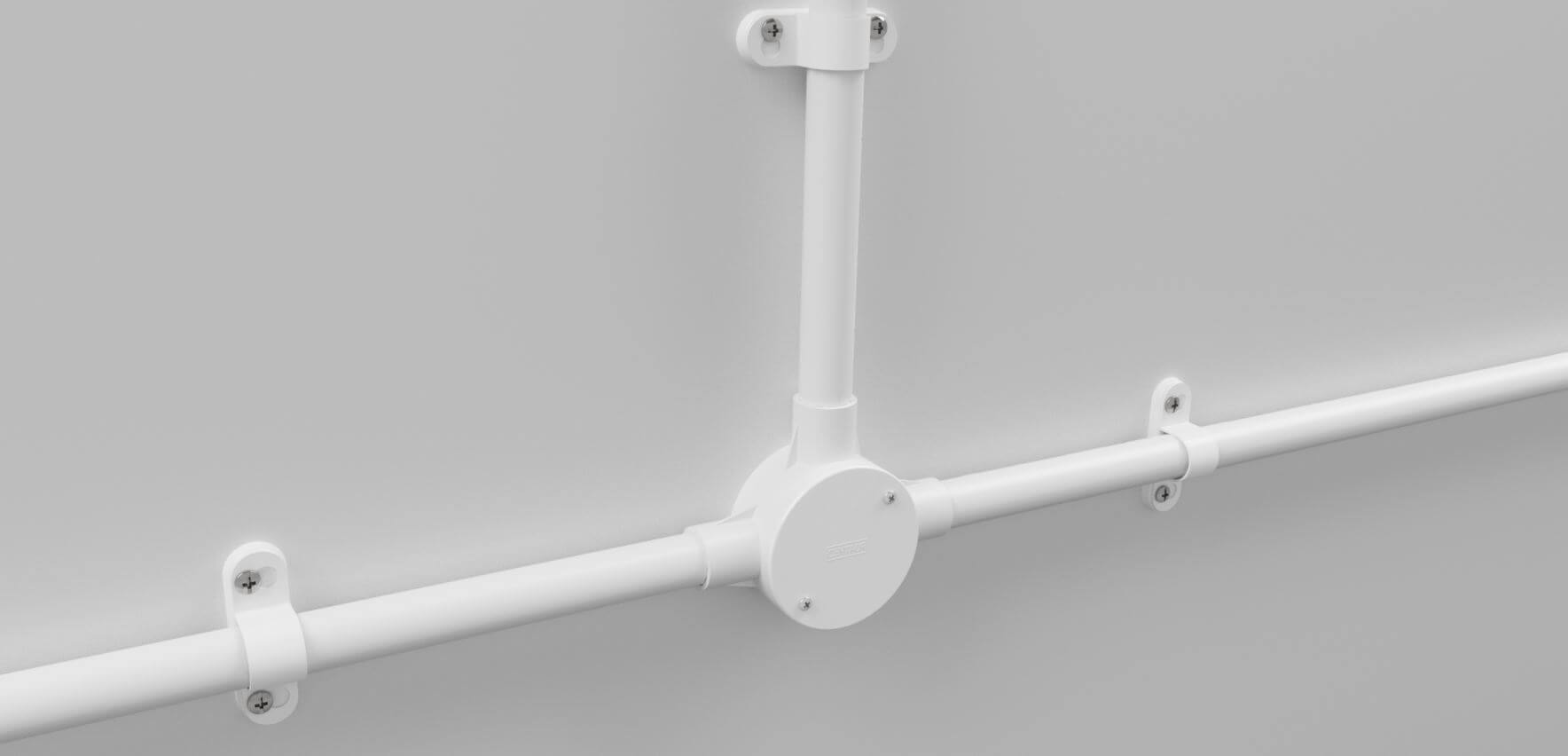

3. Easy and Efficient Installation PVC Conduit Pipe

One of the most appreciated advantages of PVC electrical conduit is its ease of installation—especially when compared to traditional metal conduit systems.

PVC conduit is significantly lighter than metal options, reducing the physical effort and labor costs associated with handling and mounting.

While rigid PVC conduit may require additional fittings such as PVC elbows, PVC conduit tee connectors, or sweep elbow bends, it can be quickly assembled using PVC primer and glue, making the joining process both secure and straightforward.

Although flexible conduit—both metallic and non-metallic—generally offers greater maneuverability and can be easier to route around obstacles, PVC flexible conduit still stands out due to its simple cut-and-glue method and compatibility with standard accessories like gang boxes, switch boxes, and outdoor junction boxes.

Additionally, PVC electrical conduit connectors and rigid conduit connectors are often designed for easy push-and-twist assembly, without the need for screws or locking rings commonly required in metal conduit connectors or EMT conduit connectors.

PVC, on the other hand, offers smooth interior walls that reduce friction during pulling wire through conduit, lowering the chances of insulation damage and speeding up the overall process.

When installing metal systems, installers must also account for potential issues like the risk of damaging wires at the conduit ends during wire pulling—especially in sharp bends or poorly deburred edges.

Moreover, installing metal conduit—such as EMT, rigid steel conduit—often involves the use of specialized tools like metal conduit benders, metal conduit pipe cutters, and a variety of metal conduit fittings and connectors for conduit.

These require threading, tightening screws, and sometimes sealing, which can slow down installation and increase complexity.

For outdoor use, pairing waterproof electrical boxes or outdoor outlet boxes with PVC conduit ensures a weather-resistant and code-compliant system without requiring extensive protective measures and worry about the rust protection.

Overall, for contractors and electricians looking to reduce labor time, avoid specialized metalworking tools, and streamline the installation of underground or surface-mounted systems, PVC conduit offers a user-friendly and efficient solution.

4. Cost Efficiency of Electrical Pipe PVC Conduiting

We’ve mentioned cost-saving advantages briefly in earlier sections—PVC conduit is also significantly lighter than metal electrical conduit, which means it can be transported and installed by fewer people without heavy lifting tools.

This reduces labor costs and speeds up installation—especially important in projects with long conduit runs and multiple conduit sizes.

And here we take a closer look at how PVC conduit provides cost efficiency in a more complete way.

Lower Material Costs of PVC Conduit

When comparing prices, PVC conduit is generally a more cost-effective option than metal conduit, particularly when comparing products with similar strength levels.

For example, a 10 ft length of Schedule 40 PVC conduit typically ranges from $6 to $20, depending on diameter and supplier. In contrast, EMT conduit of similar size may cost $10 to $30, and rigid galvanized steel conduit can reach $50 or even over $100 per 10 ft. In some extreme cases, prices of rigid metal conduit even exceed $1000 per bundle, especially for large conduit sizes or heavy-duty installations.

The prices referenced here are based on publicly available listings from Google Shopping and are for general reference only. For accurate and up-to-date pricing, please consult directly with your supplier or distributor.

If you’re interested in our PVC conduit pipe or want to get a quote, feel free to send us an email through the Ctube website.

Savings on Conduit and Accessories and Tools

PVC conduit also reduces the need for specialized tools and accessories. Installing metal conduit often requires a metal conduit bender, a metal conduit cutter tool, and multiple metal conduit connectors such as emt conduit connectors, rigid conduit connectors, or connectors for conduit in different configurations.

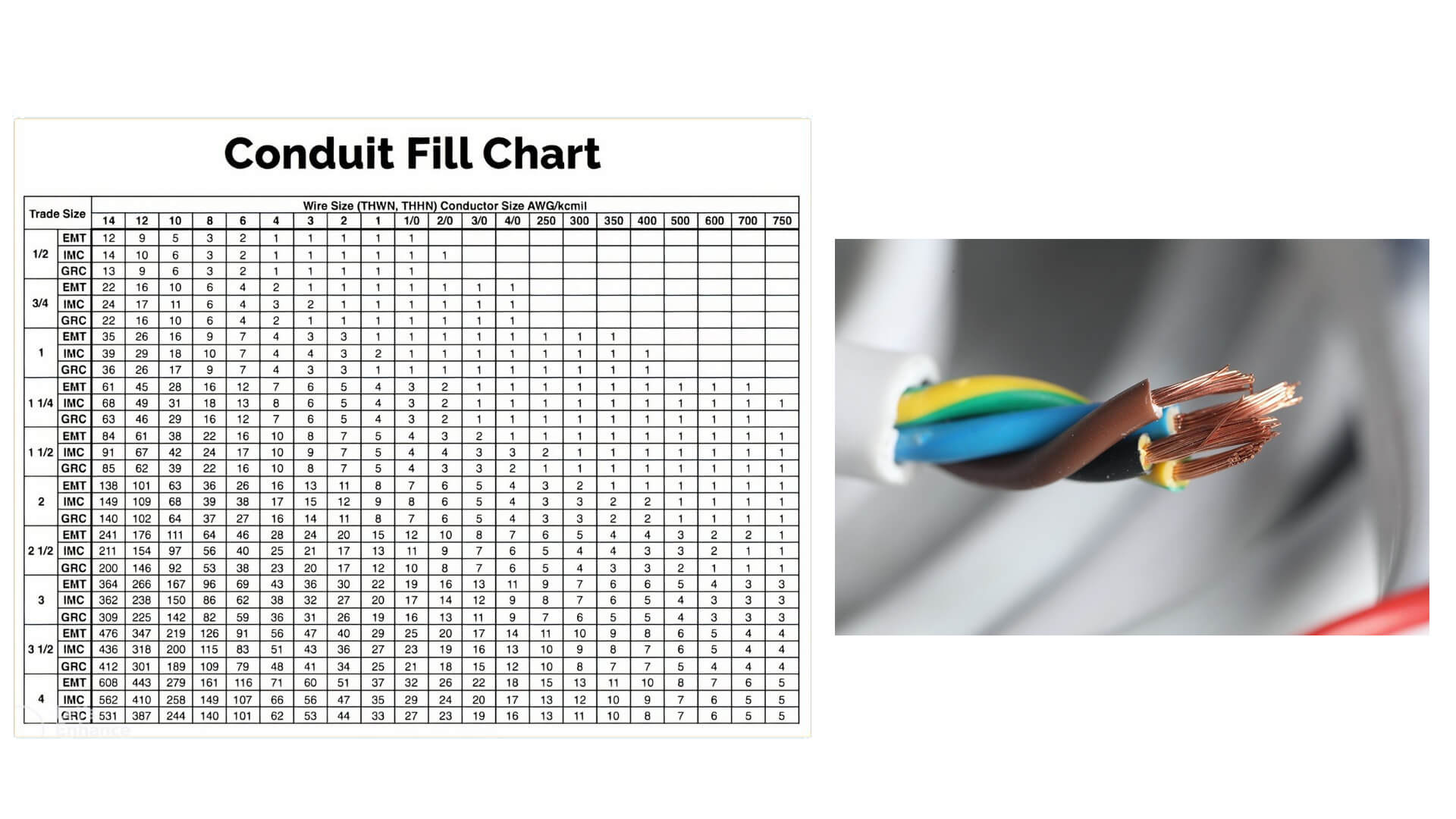

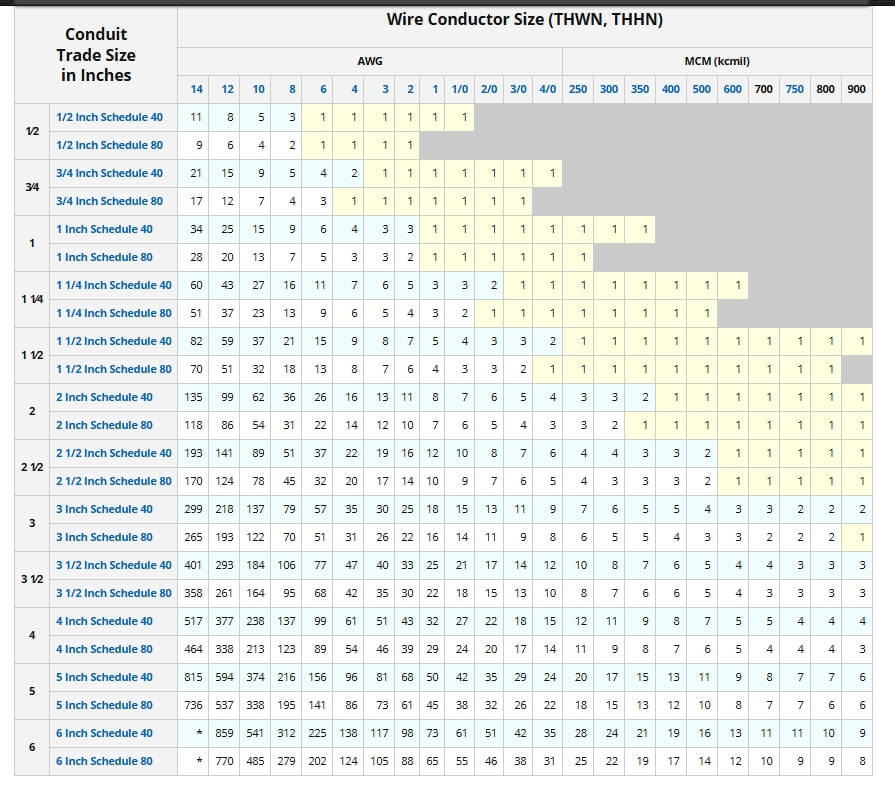

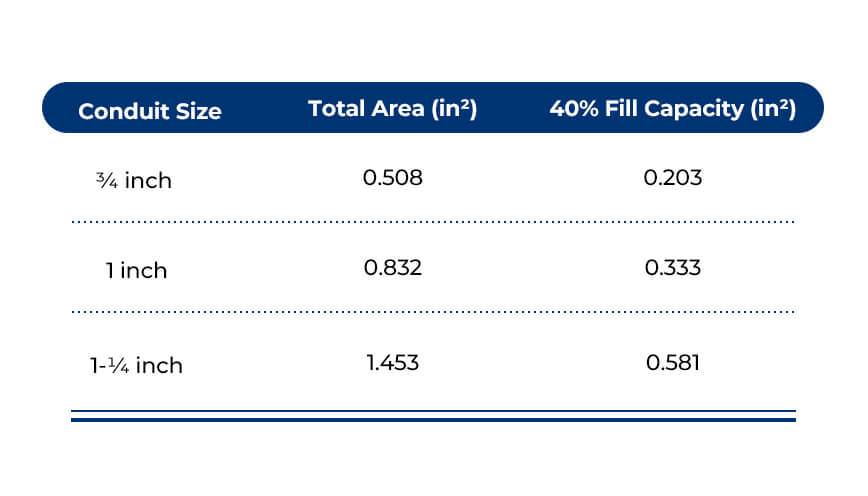

Each adds to both cost and complexity. You’ll also need tools for bending conduit offset and conduit fill calculations to avoid overloading tight metal bends.

In contrast, PVC conduit can usually be cut with a basic hand tool and connected with PVC elbows, PVC conduit tees, sweep elbow bends, or PVC pipe elbow joints using primer and glue—a simple process known as glueing electrical conduit.

There’s no need for screw tightening or grounding, and the fittings, like electrical box fittings, gang boxes, switch boxes, outdoor outlet boxes, or outdoor junction boxes, are typically plastic-based and waterproof by design.

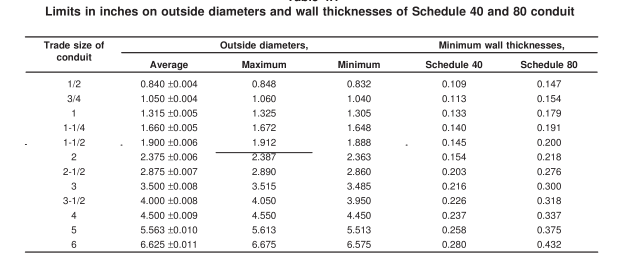

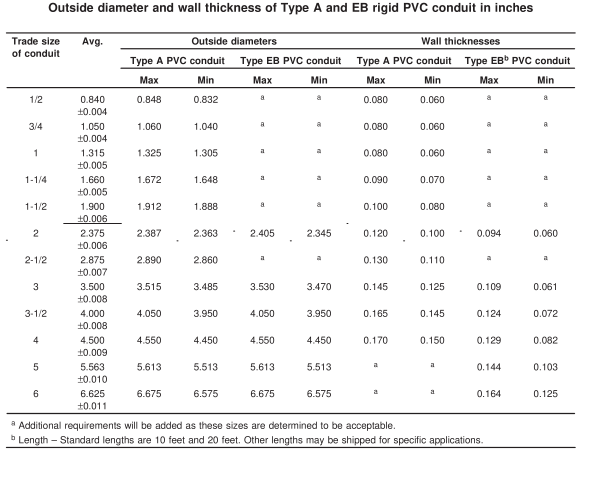

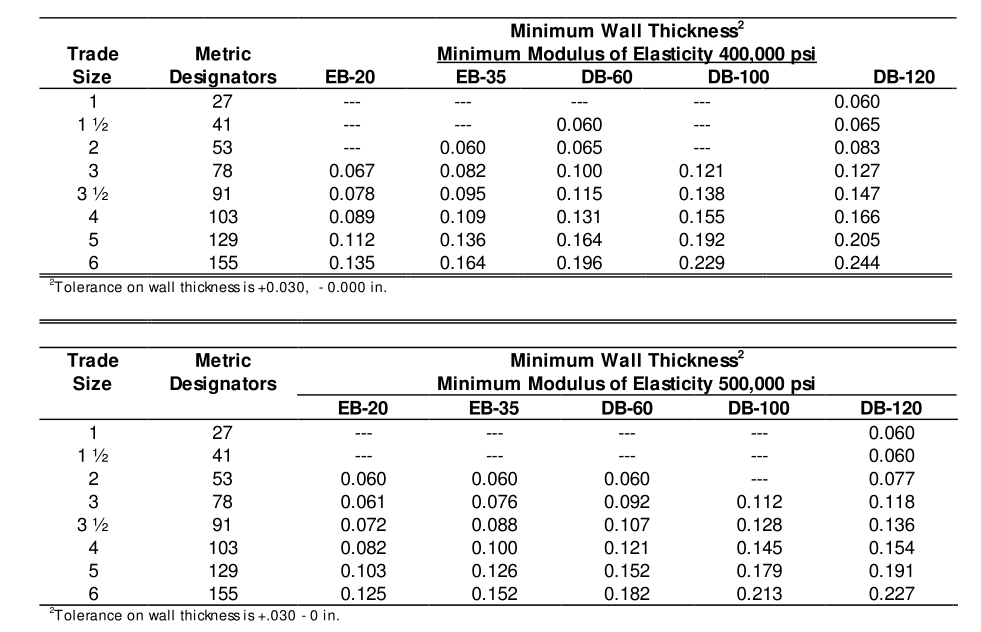

While PVC conduit such as Schedule 40 and Schedule 80 might cost more than basic emt conduit, they deliver higher impact resistance and durability in harsh environments—without requiring anti-corrosion coatings or grounding hardware. That makes them more cost-effective in the long run, especially when comparing total lifecycle costs.

PVC conduit systems also integrate smoothly with HDPE, RTRC, or metal conduit in hybrid installations, offering designers flexibility without sacrificing budget control.

5. Non-Conductive A Key Safety Advantage of PVC Conduit

One of the major advantages of PVC conduit—whether it’s rigid PVC conduit or PVC flexible conduit—is that it is non-conductive by nature.

Made from polyvinyl chloride, this type of electric conduit does not conduct electricity, which significantly reduces the risk of electric shock during installation or maintenance.

This property makes it an ideal choice for residential, commercial, and industrial electrical systems where safety is a top concern.

In contrast, rigid metal conduit (RMC), galvanized conduit, and flexible metal tubing (FMT) are made of conductive materials like steel or aluminum. Tthese metal options require a separate grounding system to ensure safety.

Moreover, the non-conductive property of PVC supports better safety practices when using conduit cutter tools or performing conduit fill calculations and layout planning.

For applications that involve moisture exposure—such as underground electrical installations or areas near water sources—PVC’s insulating characteristic becomes even more valuable. In such cases, even galvanized conduit or coated flexible metal tubing may corrode over time and lose insulation integrity, while PVC conduit retains its performance without posing a shock hazard.

6. Durability of Electrical Pipe Polyvinyl Chloride Conduit

You may have already noticed how durable PVC conduit is when we talked about corrosion and rust resistance, that’s because durability isn’t just one feature—it’s something that shows up in many different ways throughout the performance of polyvinyl chloride conduit.

In fact, these performance features are all underpinned by one fundamental characteristic: the inherent mechanical strength of PVC.

We use the UL 651 Standard for Safety for Schedule 40, 80, Type EB and A Rigid PVC Conduit and Fittings as an example to show the key durability tests that high-quality PVC conduit must pass.

Tensile Strength: This test checks if the conduit can stretch without breaking. It makes sure the pipe stays strong when pulled during installation.

Impact Resistance: This test drops a heavy object on the pipe to see if it cracks. It shows how well the conduit handles bumps or hits, even in cold weather.

Low Temperature Handling: This test makes sure the conduit won’t break when bent or installed in cold climates.

Crush Resistance: This test presses down on the conduit to check if it flattens. It ensures the pipe can handle weight from soil, concrete, or equipment.

Deflection Under Load: This test checks how much the pipe bends under pressure. A strong pipe shouldn’t sag too much.

Sunlight Resistance: This test exposes the pipe to UV light to see if it weakens. It helps ensure the conduit won’t crack or fade outdoors.

Water Absorption: This test checks how much water the pipe absorbs. Good PVC conduit should stay dry to protect wires inside.

Joint Water Tightness: This test checks if water can get through the pipe’s connection points. It helps keep electrical systems safe.

Pipe Stiffness: This test measures how stiff the pipe is. Stiff pipes are better for underground and heavy-duty use.

Aging of Rubber Parts: If the conduit uses rubber rings or seals, this test makes sure they last a long time and don’t wear out too quickly.

These testing protocols, often required by UL, ASTM, or NEC standards, validate that PVC conduit systems won’t crack, collapse, or degrade over time—even under challenging conditions.

This is particularly important for underground installations or exposed environments where soil shifts, temperature swings, or vibration from nearby construction might otherwise damage more fragile materials.

In this way, even though the word “durability” might sound simple, it’s the result of careful material science, rigorous testing, and long-term real-world performance. For contractors and engineers, choosing PVC conduit isn’t just about upfront convenience—it’s a decision that secures a project’s reliability far into the future.

7. Conclusion

Throughout this article, we’ve explored the key benefits of PVC conduit—from its resistance to corrosion and ease of installation, to its cost efficiency, safety, durability, and non-conductive properties. Whether you’re running conduit underground, installing outdoor electrical systems, or managing indoor wiring, PVC offers a lightweight, affordable, and reliable solution.

We hope this guide has provided you with practical insights and helped answer your questions about choosing between PVC and metal conduit systems. Thank you for taking the time to read—we aim to make your decision-making process easier and more informed.

At Ctube, we’re proud to offer a wide range of high-quality PVC conduit and fittings, including schedule 40 PVC conduit, schedule 80 PVC conduit, and flexible conduit options. Also provide buried electrical conduit like Type EB, DB.

All our products meet rigorous standards like UL 651, UL 1653, CSA C22.2 and AS/NZS 2053, ensuring safe and durable performance in demanding environments.

Whether your project is residential, commercial, or industrial, Ctube is here to support you with dependable solutions and expert guidance.

For more product information or to request samples, feel free to contact our team or visit our website. We’re always here to help you build with confidence.

FAQs

Q1: When to use metal conduit vs PVC conduit?

Use metal conduit when you need extra strength or protection against impact—like in exposed areas or commercial buildings. Use PVC conduit when you want something lightweight, easy to install, and resistant to rust—especially for underground or outdoor use.

Q2: How to cut pvc conduit?

To cut PVC conduit, use a PVC cutter tool, a fine-tooth saw, or a miter saw. Just measure your length, mark it, then cut straight across—be sure to smooth the edges with a deburring tool or sandpaper to avoid sharp edges.

Q3: Do you glue electrical conduit?

Yes, electrical conduit, particularly PVC conduit, is typically glued using a special solvent cement. This cement is applied to the ends of the conduit and fittings to create a secure, watertight bond.

The process involves cleaning the surfaces first, applying the solvent cement, and then quickly joining the pieces together while ensuring they are properly aligned.

The joint should be left to cure for a certain amount of time to achieve maximum strength. Always follow manufacturer instructions and local electrical codes when using solvent cement.

5 Benefits of Using PVC Electrical Conduit in Your Next Project Read More »