Understanding PVC Conduit Fill Charts: A Comprehensive Guide (2025)

1. Introduction

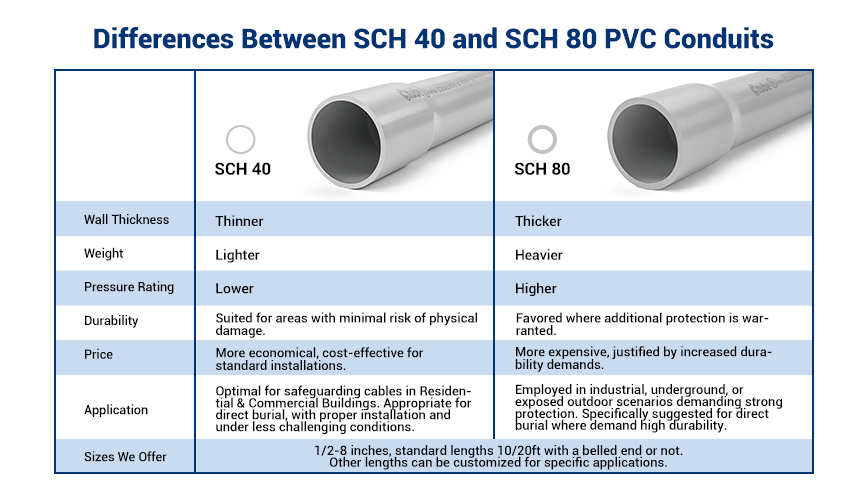

When talking about electrical conduit, most people focus on the obvious choices—what material to use, which type to go for (like Schedule 40 or Schedule 80), and what size fits the job. These are all important decisions. But there’s one more factor that often flies under the radar, even though it’s just as critical: how much wire you can actually put inside the conduit. That’s where PVC conduit fill charts come into play.

These charts are more than just technical tables—they’re practical tools used by electricians, contractors, and engineers to make sure they don’t overload a conduit with too many wires.

In this post, you’ll learn how to determine the right amount of wire that can safely go into different types and sizes of PVC conduit. And also the other conduit material. We’ll show you how to read and use conduit fill charts, understand basic wire sizing, and consider key factors like insulation type, conduit material, and installation environment. Hope this post helpful. And now we start.

2. What is a Conduit Fill Chart and Why it matter?

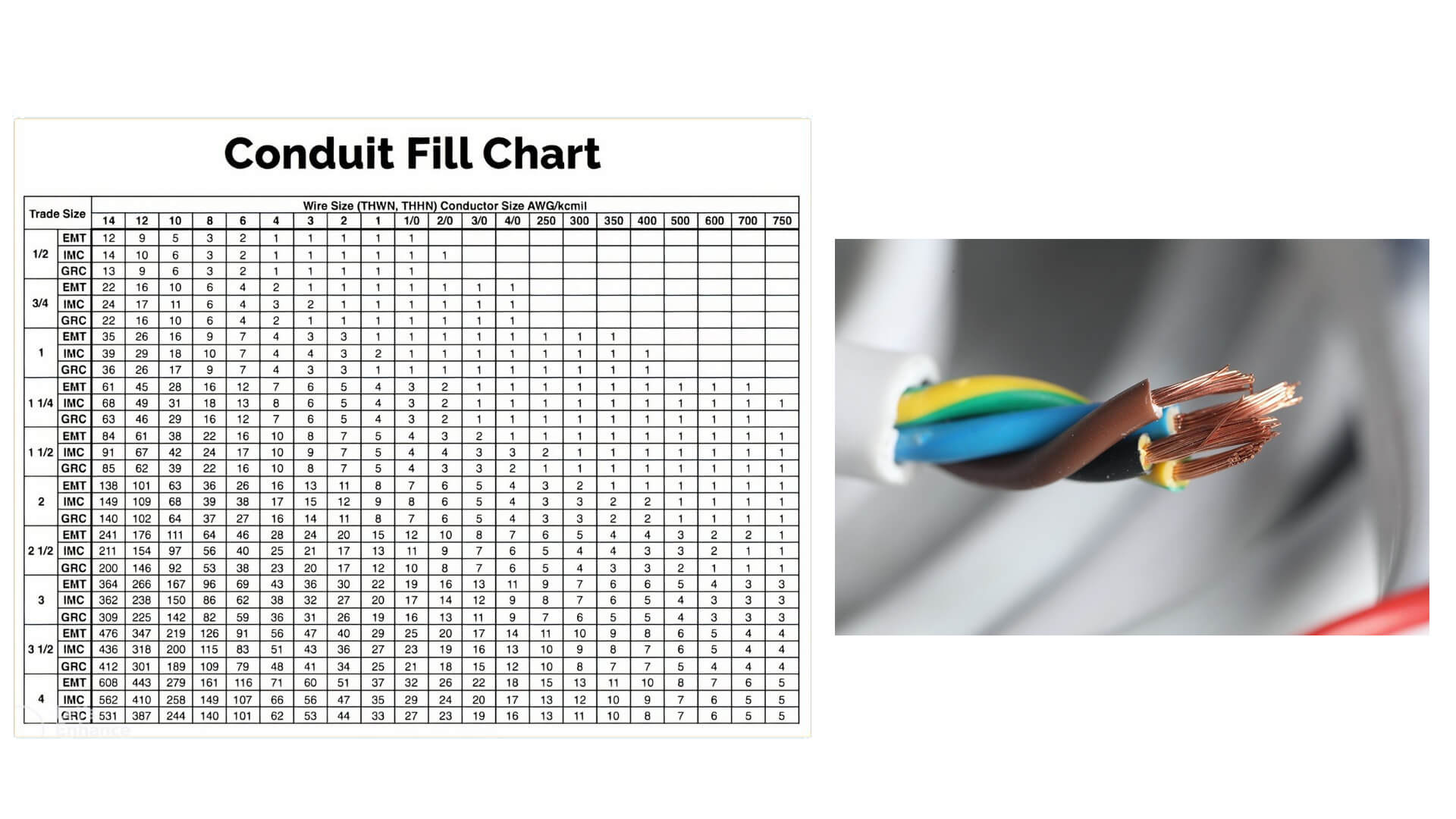

A conduit fill chart is a reference table that tells you how many electrical wires / cables (or conductors) of a certain size can safely fit into a specific size of conduit. These charts are based on standards set by codes like the National Electrical Code (NEC) and Canadian Electrical Code (CEC) to ensure proper airflow around the wires and prevent overheating.

Why does this matter? Because cramming too many wires into a conduit can lead to increased resistance, heat buildup, damaged insulation, and even electrical fires. Fill charts help you avoid all of that by giving you exact limits—usually shown as a percentage of the conduit’s internal area.

3. Wires, Cables, and Conductors – What’s the Difference?

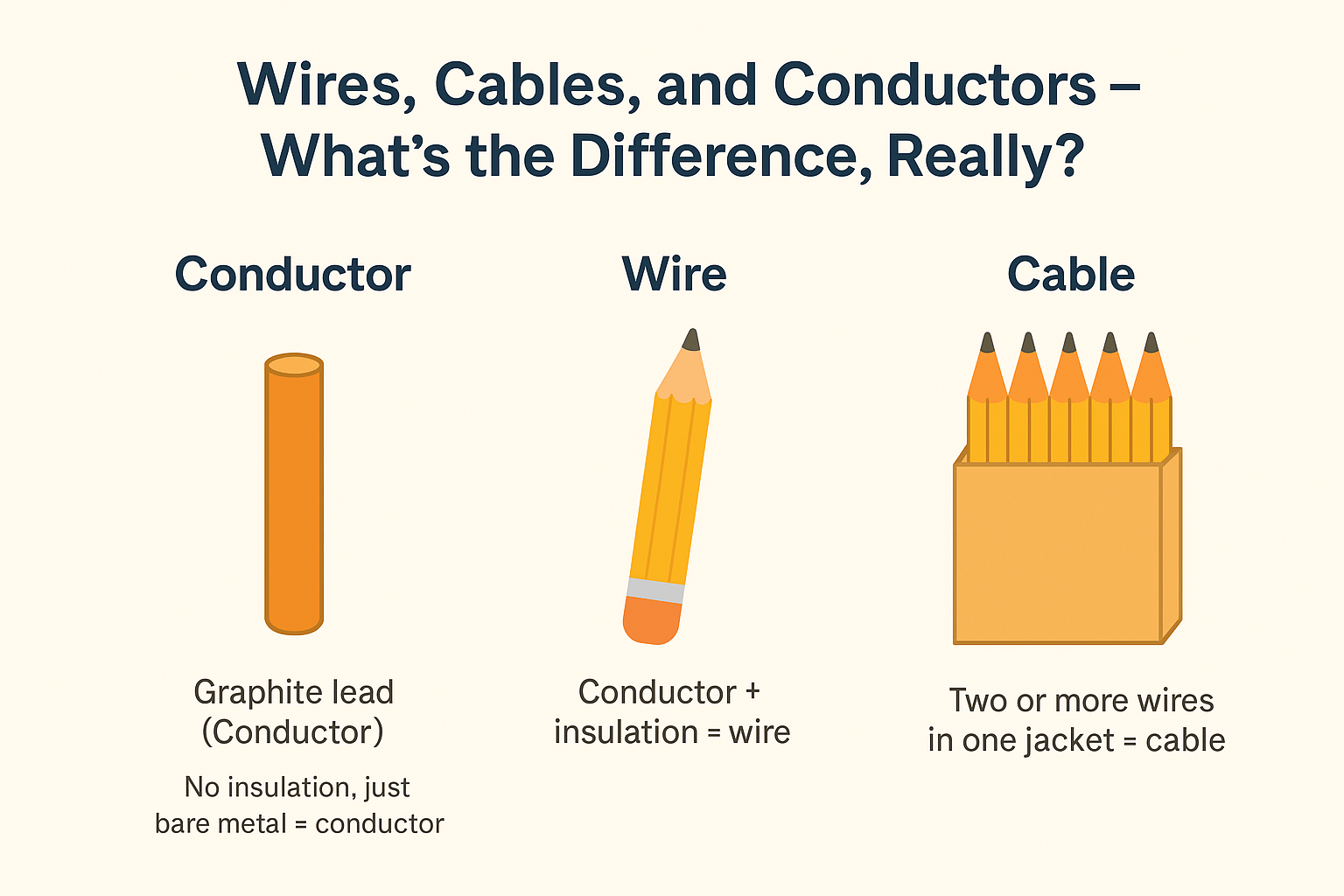

In the last section, we have mentioned about cables and wires. And in everyday conversations, we tend to use the words wire, cable, and conductor like they all mean the same thing. And honestly? That’s totally normal. On the job site or even in general electrical work, people say “pull a wire” or “run a cable” without always being super specific. But when it comes to things like conduit fill calculations, those small differences start to matter.

A conductor is just the metal part inside—usually copper or aluminum—that electricity flows through. It’s the starting point. No insulation, just bare metal = conductor.

A wire is a conductor that has been wrapped in insulation, making it safe to handle and install. So when we say “wire,” we’re usually talking about one insulated conductor. So, Conductor + insulation = wire.

A cable is a group of two or more insulated wires, bundled together in an outer jacket. It’s like packaging multiple wires together for easier installation. That means, Two or more wires in one jacket = cable.

Let’s say for using analogy as the picture show above.

- The conductor is the graphite lead in a pencil.

- The wire is the full pencil, with wood casing protecting the lead.

- The cable is the box of pencils, bundling several together.

Now that we’ve cleared up what wires, cables, and conductors really are, you might be wondering—how do we know how many of them can safely fit inside a conduit?

In North America, the National Electrical Code (NEC) in the U.S. and the Canadian Electrical Code (CEC) in Canada lay out the rules for safe electrical installations. These codes provide the official limits for conduit fill percentages, depending on how many wires you’re pulling and what type of wire you’re using.

And here’s another key piece: the size of the wire. This is where AWG (American Wire Gauge) comes in. AWG is the standard system we use to measure wire diameters. Smaller numbers mean thicker wires, which take up more space in your conduit—so size definitely matters here.

Plus, not all cables are created equal. There are different cable types, like THHN, XHHW, NM, or MC, each with different insulation thicknesses and uses. And yes—the type of cable affects your conduit fill, too.

We will go through each of the important keywords mentioned here one by one such as conduit fill percentages, types of wires, cables and AWG, so you can understand them better for more details. And the first one.

4. What Are Conduit Fill Percentages?

When you install electrical wires inside a conduit, you can’t just stuff in as many as will physically fit. That’s where conduit fill percentage comes in—it’s all about how much space inside the conduit the wires are allowed to take up, based on safety and code requirements.

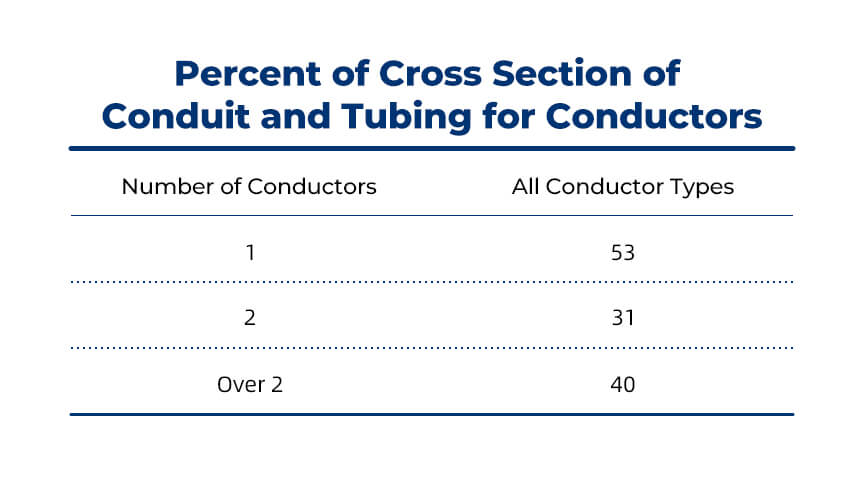

According to the NEC and CEC, the amount of fill you’re allowed depends on how many conductors you’re putting inside the conduit:

One wire: You can fill up to 53% of the conduit’s inner area.

Two wires: You’re limited to 31%.

Three or more wires: You can use up to 40% of the space.

5. What is an American Wire Gauge?

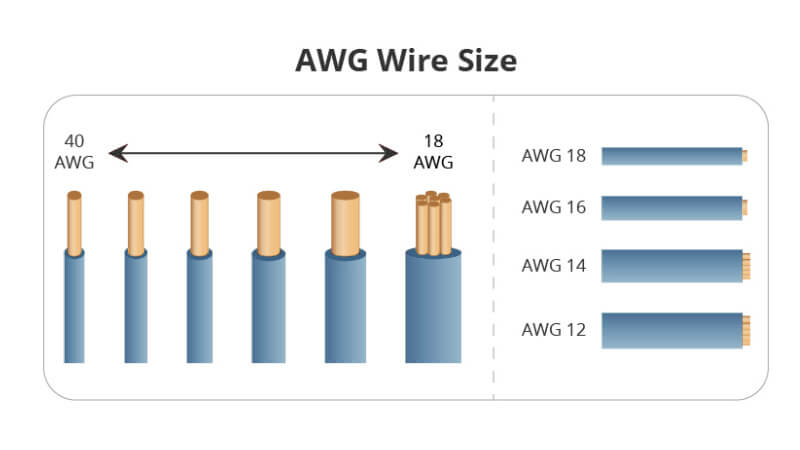

Let’s talk about AWG, short for American Wire Gauge. You’ll see this everywhere when dealing with electrical wiring. Basically, it’s a standard way to measure the thickness (or diameter) of a wire.

The AWG scale is inversely proportional to the wire diameter; a higher AWG number indicates a thinner wire, while a lower number corresponds to a thicker wire. So it means the higher the number, the thinner the wire. For example, a 14 AWG wire is actually much thinner than a 6 AWG wire.

Why does this matter? Because thicker wires can carry more electricity, and they take up more space inside your conduit. When you’re calculating conduit fill, you’ll need to know the AWG of your wires to figure out how much space each one uses.

In short, AWG helps you pick the right size wire for the job, and helps make sure your conduit isn’t too full.

And the next section we introduce the types of cables and wires.

6. Common Wire and Cables Types, Materials and Their Meanings

As we mentioned above, a wire is a single conductor, while a cable is a bundle of wires. And they all have different types.

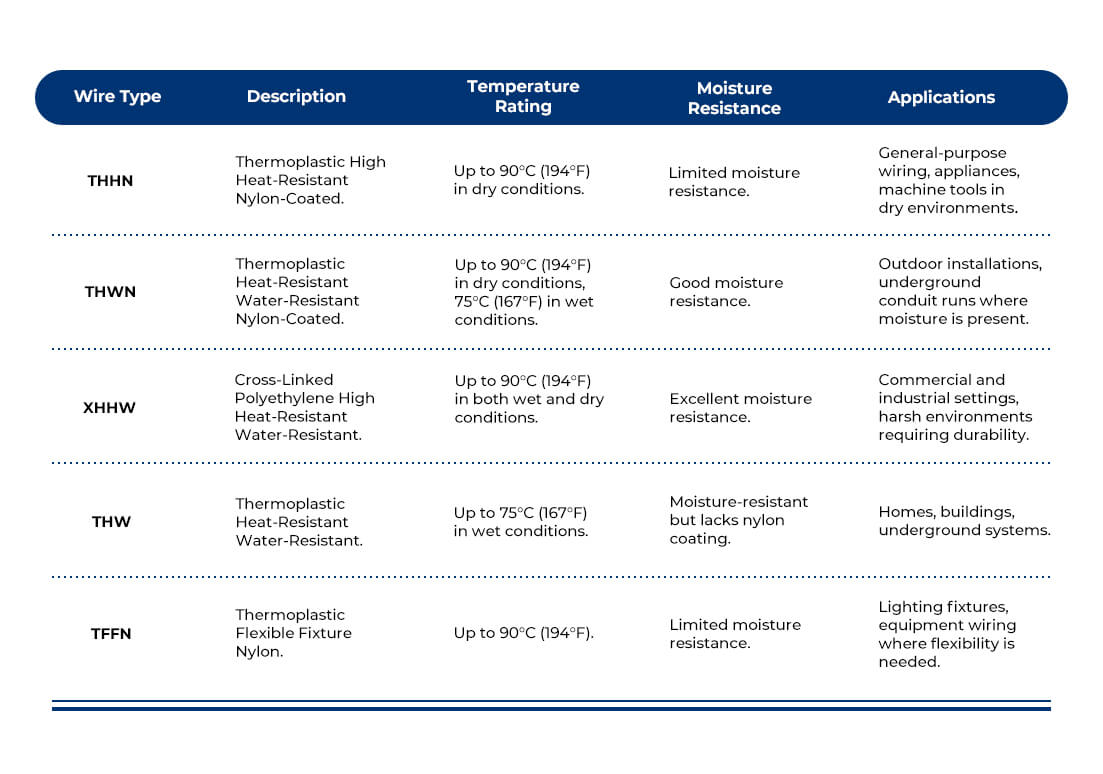

If you’ve ever looked at electrical wire and wondered what all those letters mean—don’t worry, you’re not alone. Names like THHN, XHHW, THWN might seem confusing at first, but they actually tell you a lot about how the wire is built and where it can be used.

Here’s what those letters stand for, in case you want to decode a wire type on the fly:

Letter | Meaning |

T | Thermoplastic insulation |

H | Heat resistant |

HH | High heat resistance |

W | Water resistant |

N | Nylon jacket for added protection |

X | Cross-linked polyethylene insulation |

F | Flexible (as in TFFN for fixture wire) |

And here we introduce some common types. To better understand, here we make a comparison table.

Just like wires, cables come in different types, each with its own name, structure, and purpose. Let’s take a look at what makes each one unique.

Underground Feeder (UF) Cable: UF cable is made to go directly into the ground without needing a conduit. It’s water-resistant, tough, and built to handle outdoor conditions. You’ll often see it used for garden lights, water pumps, or power going out to sheds and garages.

Metal-Clad (MC) Cable: MC cable comes with a strong metal jacket that protects the wires inside. It also helps with grounding. It’s ideal for places where the cable might get bumped or damaged—like factories, warehouses, or commercial buildings.

Armored (AC) Cable: AC cable has a flexible metal covering, which gives it good protection while still being easy to bend. It often includes a bonding strip for grounding. It’s commonly used in basements, older buildings, and small commercial jobs.

Non-Metallic Sheathed (NM) Cable: NM cable, often called Romex, has multiple wires wrapped in a plastic outer layer. It’s lightweight, affordable, and easy to run through walls. Perfect for wiring lights, outlets, and appliances in homes.

Coaxial Cable: Coaxial cable is used to carry high-frequency signals, like your TV or internet. It has a center wire, surrounded by insulation, a metal shield, and a protective jacket. It’s built to reduce signal loss and block interference.

Twisted Pair Cable: This cable has two wires twisted around each other to help cancel out electrical interference. It’s often used in phones, computer networks, and other communication systems where clean signals are important.

Single-Conductor Cable: A single insulated wire, often used for grounding, simple electrical systems, or connecting to batteries and motors.

Multi-Conductor Cable: This cable bundles several insulated wires together inside one jacket. It’s useful when you need to run multiple signals or power lines through the same route—like in control panels or sound systems.

7. How to Use a PVC Conduit Fill Chart?

Alright, now that we’ve gotten all the technical jargon out of the way, let’s dive into the real nitty-gritty: how to actually use a PVC conduit fill chart. We’ll break it down step by step in the following.

First of all, let’s break it down into three simple steps. It’s pretty straightforward, but there are some important details to watch out for along the way. We’ll go through each step one by one so you don’t miss anything.

The steps generally are:

- Figuring out the size and type of your conduit,

- Identifying the wire size and type,

- Calculate the Total Area of All Wires,

- Apply the NEC Fill Percentage Rule,

- Checking the fill chart and doing the math to make sure you’re not overstuffing the conduit.

And in different situation, the steps can be adjusted. We will make the different examples in the followings.

It’s also important to keep in mind that different materials of conduit can affect how much space is available for wires. Different conduit materials (like PVC, EMT, flexible metal, etc.) have different fill capacities and code requirements.

This guide focuses specifically on PVC conduits. If you’re using a different material, make sure to consult the appropriate fill chart for that type.

Now that you’ve seen the overall process, let’s break it down with a real-world scenario so it’s easier to understand and apply on the job.

About checking the first and second step we have mentioned, the dimensions and details about the wire—such as its area and insulation type—are typically provided by the supplier at the time of purchase.

For example, the supplier’s product specifications or labels on the wire tube will indicate the wire’s area (usually in square inches)

- Key Takeaways: What to Do in Different Scenarios

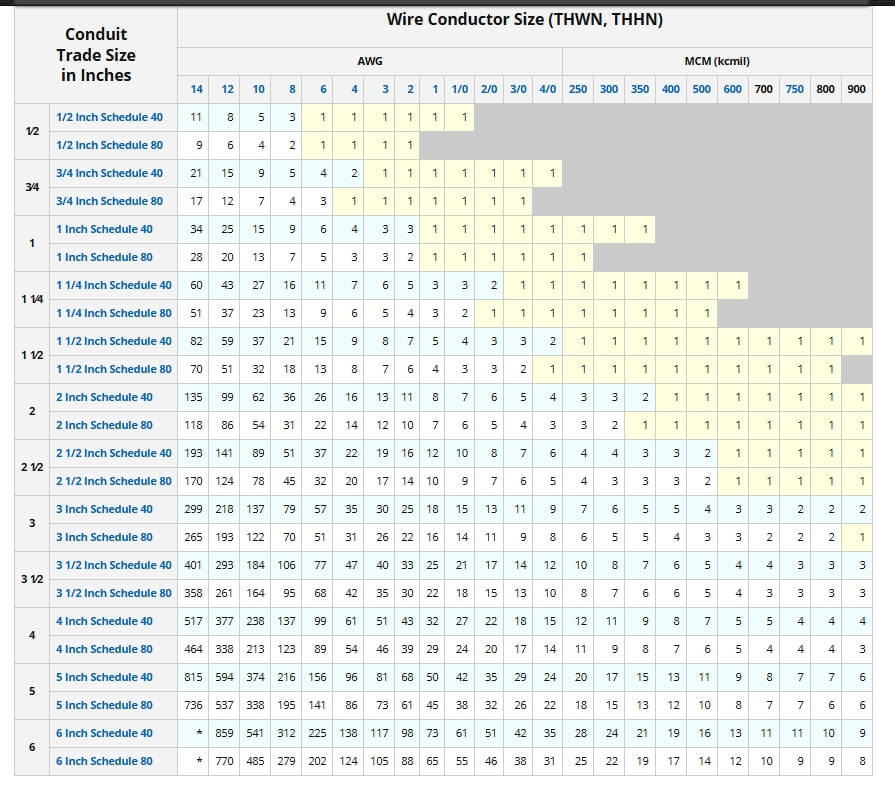

- Limited Conduit Size: If you are limited to using only one size of conduit, like a 3/4 inch Schedule 40 PVC conduit, and you need to determine how many 12 AWG THHN wires can safely fit, here’s how to use the fill table:

- Locate Conduit Size: Find the row that corresponds to your conduit size, which is “3/4 Inch Schedule 40”.

- Locate Wire Size: Find the column that corresponds to your wire size, which is “12 AWG”.

Find the Intersection: At the intersection of the “3/4 Inch Schedule 40” row and the “12 AWG” column, you will find the number that indicates the maximum number of 12 AWG THHN wires that can safely fit in the conduit.

Based on the table, the number at the intersection is 15.

Therefore, you can fit 15 12 AWG THHN wires safely into a 3/4 inch Schedule 40 PVC conduit without exceeding the maximum fill limit.

Limited Wires, Multiple Conduit Choices: If you have a fixed number of wires but can choose the conduit size, you’ll calculate the total wire fill and then pick a conduit size that offers enough room (while staying within the fill limits) for the wires you need to use.

Let’s say you’ve got 10 pieces of 10 AWG THHN wire that need to run through a conduit. You don’t want to split them up—you want all of them in the same conduit. Luckily, you have a few different conduit sizes available to choose from, like ¾ inch, 1 inch, and 1¼ inch Schedule 40 PVC conduit.

Steps: You have 10 pieces of 10 AWG THHN wire. Check the Fill Chart above for each available conduit size, find the entry that corresponds to a 10 AWG.

Determine Conduit Size

3/4 Inch Schedule 40: Can fit 9 wires. Not enough for your 10 wires.

1 Inch Schedule 40: Can fit 15 wires.

Select the Conduit

You can use a 1 Inch Schedule 40, because it can accommodate 15 pieces. Therefore, 1 Inch Schedule 40 is the smallest suitable conduit for your needs.

In the process, maybe you confused about why we do not Apply NEC Fill Percentage Rule, and here we tell you the reason and When to Manually Apply the NEC Fill Percentage Rule.

- Mixed Wire Sizes: When you have different sizes of wires in the same conduit.

- Uncommon Wire Types: When using wire types not listed in the chart.

- Complex Calculations: When the installation involves a large number of conductors or specific requirements not easily found in a chart.

- Verification: When you need to verify that the values in the chart align with your specific installation conditions.

Same Scenario, how to check? You have 10 pieces of 10 AWG THHN wire. Available conduit like ¾ inch, 1 inch, and 1¼ inch Schedule 40 PVC conduit.

Step 1: Look Up the Area of One Wire

From NEC Chapter 9, Table 5, we see:10 AWG THHN = 0.0211 in² per wire

You have 10 wires: 0.0211 in² × 10 = 0.211 in² total

NEC Chapter 9, Table 5, lists the approximate cross-sectional areas of different wire types. Each wire insulation type has a slightly different area, even for the same wire gauge. You find this number from the official NEC fill tables, or sometimes manufacturers will list it on their wire datasheets. The tool in this website maybe helpful.

Step 2: Check Each Conduit Option

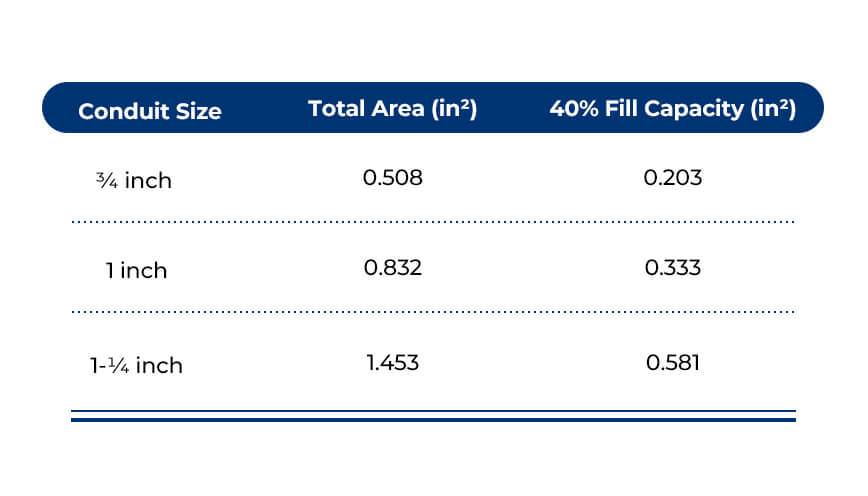

From NEC Chapter 9, Table 4, here are the 40% fill capacities for Schedule 40 PVC Conduit:

NEC Chapter 9, Table 4 is a key table from the National Electrical Code (NEC). It shows the total cross-sectional area and the maximum wire fill capacity for different sizes and types of conduit. The tool in this website maybe helpful.

8. Conclusion

Understanding PVC Conduit Fill Charts: A Comprehensive Guide (2025) Read More »