Comment choisir la taille du conduit pour les installations électriques

1. Introduction

When planning an electrical installation—whether it’s for your home, a commercial building, or an outdoor project—choosing the right conduit size is one of the most important steps.

If the conduit is too small, the wires won’t fit properly, which can lead to overheating, damaged insulation, and even fire hazards. If the conduit is too large, you might be wasting money and space.

We can find some asking questions like:

- What size conduit for 6/3 wire?

- What size conduit for 200 amp serivice?

- What size conduti for 8 gauge wire?

These are all great questions—and they point to a bigger issue: understanding the connection between electrical current (amps), wire size (AWG), and conduit size is the key to a safe and code-compliant installation.

This guide is designed to walk you through the entire process step by step. We’ll explain the basic terms like “amp,” “gauge,” and “AWG,” show you how to calculate the correct conduit size, and give you real-world examples to make things easier to understand.

Whether you’re a DIY enthusiast, an apprentice electrician, a contractor, or simply someone curious about how electrical systems work, we hope this guide helpful for you to choose the right conduit size.

2. Understanding the Basics Before Choosing Conduit Pipe Size

2.1 What is Amp (Amperage)?

In electrical systems, “amp” (short for amperage) is a unit that measures how much electrical current is flowing through a wire. You can think of it like water flowing through a pipe—more amps means more current is moving.

Every electrical device—like lights, appliances, or machines—draws a certain amount of amps to operate. If the current flowing through a wire is too high for the wire’s capacity, the wire can overheat or even cause a fire.

In summary, amperage tells you the size of the electrical “load”. It’s the starting point when figuring out what size wire and conduit you’ll need.

That’s why it’s important to know how many amps your system needs before choosing your wire and conduit size.

2.2 What is AWG (American Wire Gauge)?

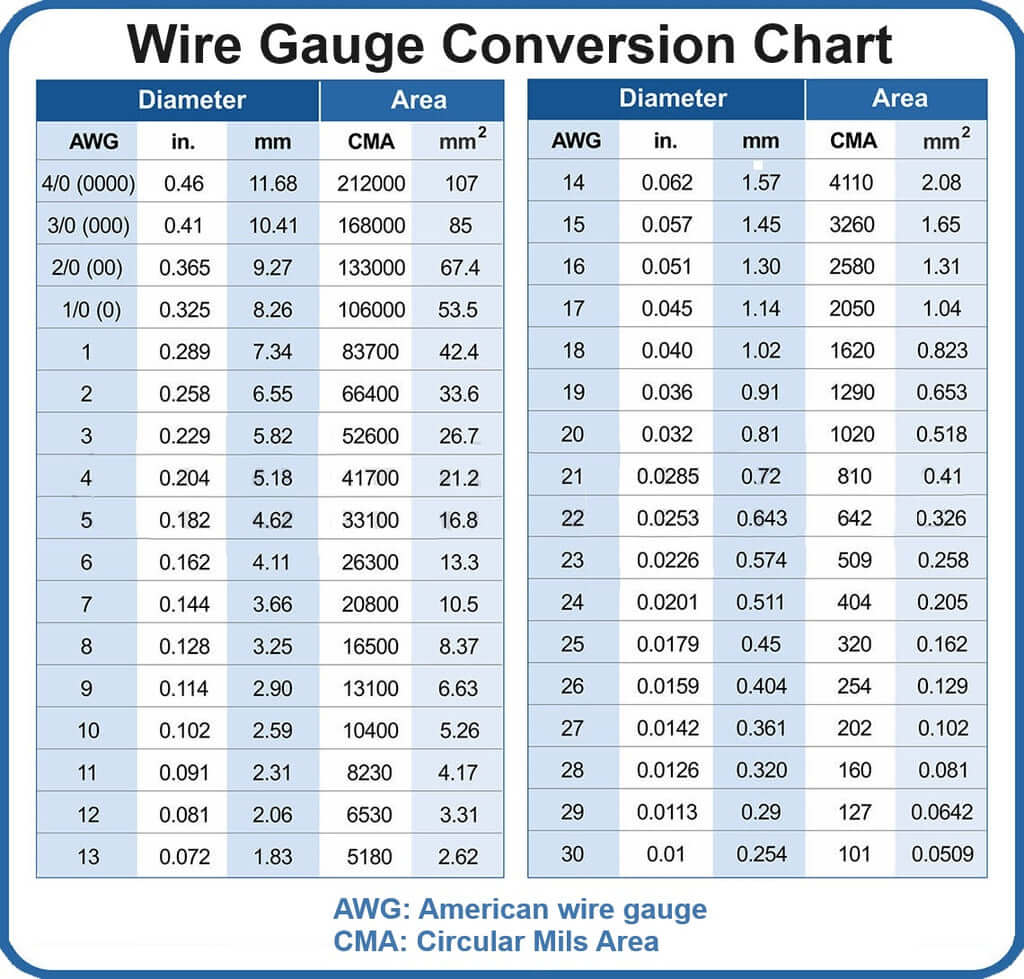

AWG stands for American Wire Gauge. It’s a standardized system used in the U.S. and many other countries to describe the thickness (or diameter) of electrical wires.

The lower the AWG number, the thicker the wire.

The higher the number, the thinner the wire.

In short, AWG tells you how thick the wire is, which determines how much electrical load it can safely handle. This is a key factor when calculating conduit size.

Additionally, when someone refers to “8 gauge” wire or “10 gauge” wire, they’re talking about the AWG of the wire.

Gauge is essentially the same as AWG. In the United States, AWG is the standard term for wire gauge, but gauge can also be used more generally to refer to wire thickness, especially in non-technical contexts.

2.3 How Amp and AWG Work Together

To safely install electrical systems, you need to consider both amps and AWG (or gauge). The ampacity of a wire (how many amps it can safely carry) is directly related to its gauge (thickness).

If you have a higher amp requirement (like for a large appliance or power system), you’ll need a thicker wire (lower AWG number) to safely carry that current.

If you need to power a 200 amp electrical panel, you’d need a much thicker wire than if you were wiring a light fixture that only draws 15 amps. The 200 amp system would require a lower AWG number (like 2 AWG or even 4/0 AWG), while the 15-amp circuit could be wired with a 14 AWG wire.

3. What are Electrical Conduit Piping Sizes and Types?

Electrical conduit is a protective tube or pipe used to enclose electrical wiring and shield it from physical damage, moisture, and other potential hazards.

Conduit size refers to the diameter or internal width of an electrical conduit.

Size of conduit determines how much wire can safely fit inside the conduit and whether the conduit can accommodate the required electrical load without risk of overheating, damage, or compliance issues.

Different conduit materials follow specific manufacturing standards, which regulate their inner diameter (ID), outer diameter (OD), wall thickness, and standard lengths.

4. What Are the Critical Considerations When Determining Conduit Size?

Okay, since we have learned about the basic and some details of electrical conduit sizes and we summarize the factors that influence us in making the conduit selecting choices.

Wire Size (AWG): As we mentioned above, the size of the wire you are using is one of the most important factors when choosing the conduit size.

The American Wire Gauge (AWG) number tells you the diameter of the wire and its current-carrying capacity. Larger wires require more space in the conduit because they have greater insulation and take up more room.

Wire Types (THHN, THWN, etc.): The insulation type of the wire affects its size and how it fits in the conduit. THHN (Thermoplastic High Heat-resistant Nylon-coated) and THWN (Thermoplastic Heat and Water-resistant Nylon-coated) are both common types of single conductor wires used in electrical installations.

Even though both wire types have similar current-carrying capacities, THWN tends to have a slightly thicker insulation compared to THHN. The extra insulation can increase the wire’s overall diameter, meaning THWN wires may need more space in the conduit than THHN wires of the same gauge.

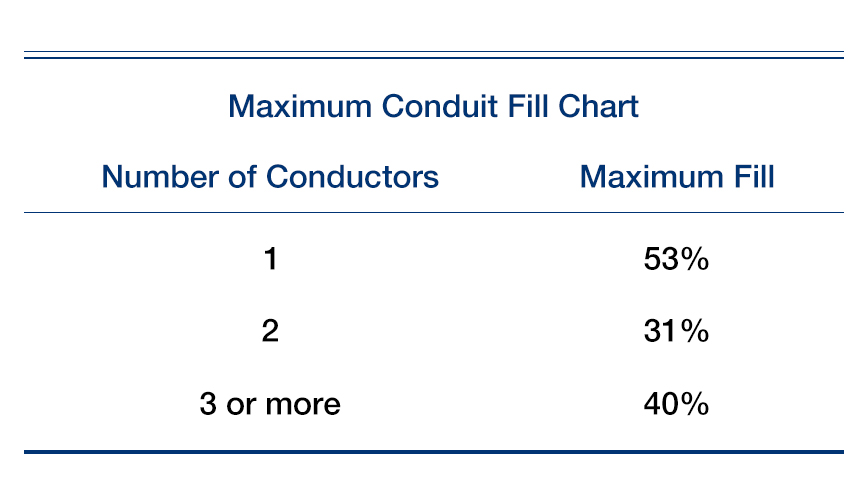

Number of Conductors: The total number of conductors, or wires, being run through the conduit impacts the size you need. More conductors mean more space is required.

In many installations, you may have multiple hot wires, a neutral wire, and a ground wire, all of which need to fit into the conduit.

Conduit Type: Different types of conduit, such as EMT (Electrical Metallic Tubing), PVC, Rigid Metal Conduit (RMC), and Flexible Conduit, have different internal diameters.

Température ambiante: In high-temperature environments, wires can overheat more quickly. When determining the correct conduit size, the ambient temperature of the area where the conduit will be installed must be considered.

High temperatures can reduce the conduit’s internal space, which means you may need to use a larger conduit to account for this factor.

Conduit Length and Bends: Longer conduit runs or those with many bends require more space for wires to ensure they’re not damaged during installation.

Bends and long runs can create friction and additional resistance, making it harder for wires to move through the conduit, especially during installation.

Expansion future: You may not need extra space for additional wires right now, but leaving room for future expansion can save time and money in the long run.

Adding wires later can require removing and replacing the conduit, which is costly and time-consuming.

5. How to Determine the Right Conduit Size?

Choosing the right conduit size is crucial to ensure safety, functionality, and compliance with electrical codes like NEC conduit size chart.

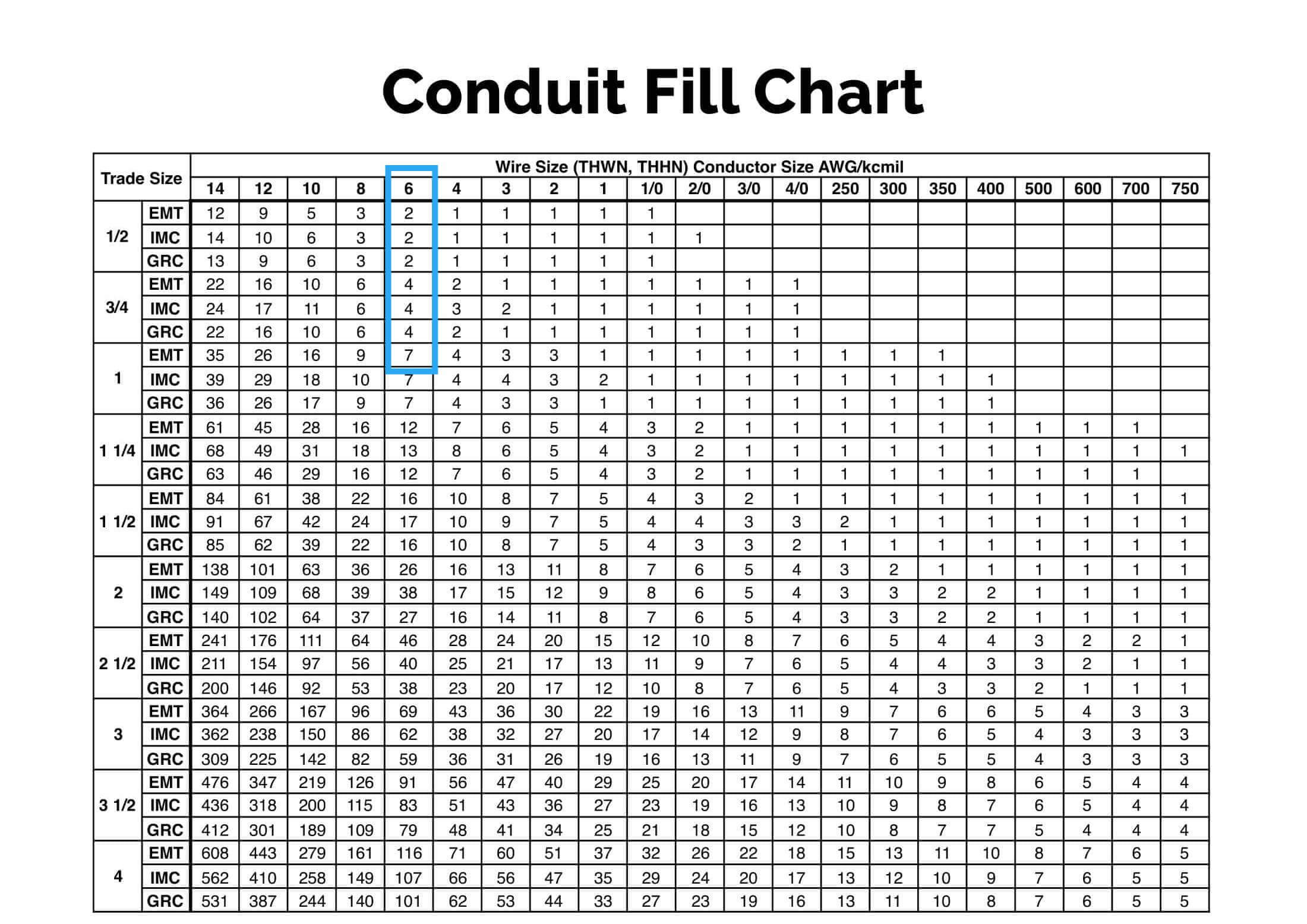

The NEC Conduit Size Chart is an essential tool for electricians and contractors to ensure that electrical installations are both safe and compliant with the National Electrical Code (NEC). This chart helps you select the appropriate conduit size based on the wire gauge (AWG), the number of conductors, and the amperage (amp) rating of the circuit.

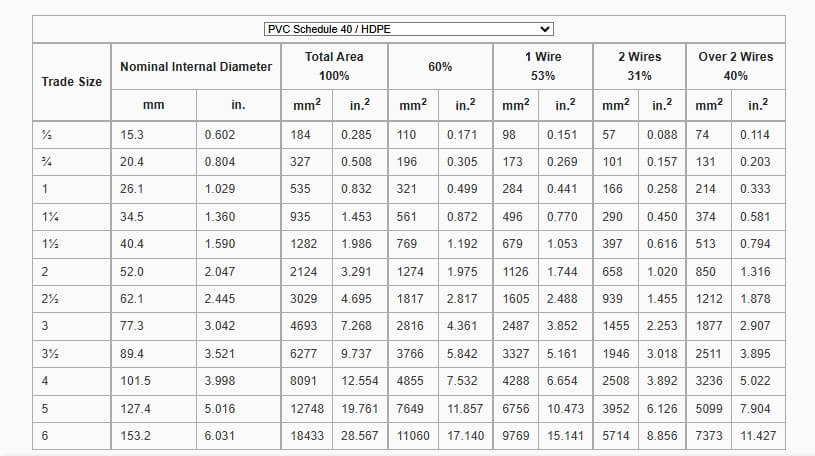

This guide concerning about PVC conduit fill chart we make the details introduction, if you have interested in conduit size chart for wire, learn more about this.

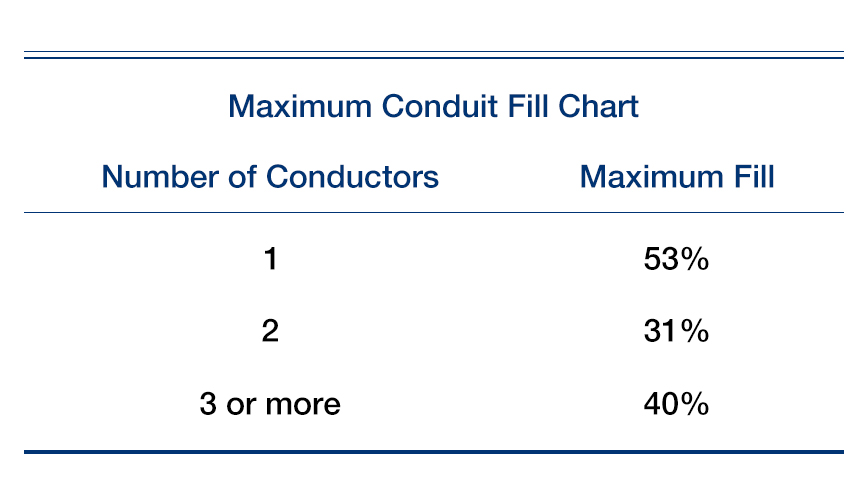

According to the NEC, a conduit should never be filled more than 40% with wires to allow for airflow and cooling. The chart will show the maximum number of conductors (wires) that can fit inside different sizes of conduit while adhering to this fill rule.

We will make different situation and help you to make the electrical conduit size calculator.

Question 1: 📌 What Size Conduit for 6/3 Wire?

What size of electrical conduit is required to properly and legally enclose a 6/3 electrical cable?

Let’s assume THHN wire, which is common in many installations. And you conduit type is EMT.

Answer 1: Look the conduit fill chart above, 6 AWG, ½ EMT can add 2 wires, and ¾ EMT can add 3 wires, ¾ EMT is okay.

Question 2: 📌 Choosing the right PVC conduit size for a 6/3 wire THHN wire?

The conduit fill chart do not mentioned above, at this time, it’s important to calculate how much space the wires will occupy inside the conduit and ensure they don’t exceed the recommended fill capacity.

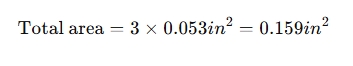

Answer 2: For 6/3 wire, there are 3 conductors, 6 AWG THHN wire has a typical outer diameter of around 0.254 inches.

And the area of one wire is 0.0507 in². For 3 conductors of 6 AWG, total area =0.1521 in².

And based on NEC guidelines (40% fill for three or more conductors),

- A ½ -inch Schedule 40 PVC conduit has a 40% fill capacity of about 0.114 in², not enough,

- A ¾-inch Schedule 40 PVC conduit has a 40% fill capacity of about 0.203 in², it’s okay,

Since your total wire area is 0.159 in², a ¾-inch conduit just barely meets the requirement.

However, if you’re also running a ground wire or want more space for pulling and cooling, use a 1-inch conduit for better safety and flexibility.

We can check for the NEC Chapter 9 Table 5 — Conductor Dimensions & Dimensions of Insulated Conductors and Fixture Wires. Tool in this website may be helpful.

If you do not use the calculator, just calculate by your self, here are the tips:

6 AWG THHN wire, which has an approximate outside diameter of 0.26 inches.

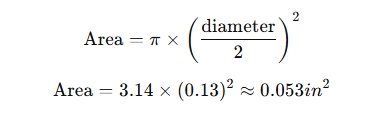

We calculate the area of one wire (assuming a circular cross-section) using this formula:

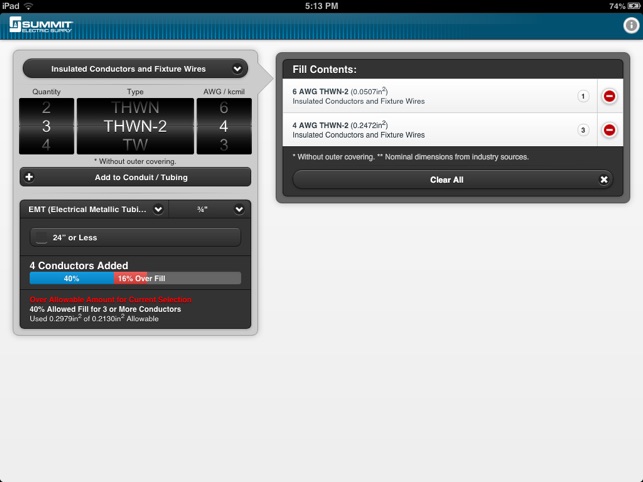

For three conductors of 6 AWG:

Question 3: 📌What size conduit for 200 amp service?

✅ To answer this clearly, let’s set the Assumptions (Standard Scenario)

Service size: 200 amps

Voltage: 120/240V single-phase (common in residential buildings)

Conductor type: Copper wire

Wire insulation type: THHN

Conduit type: Schedule 40 PVC conduit pipe

Number of conductors: 3 (2 hot + 1 neutral), ground wire not included for now

✅ Step 2: Determine the Correct Wire Size

The National Electrical Code (NEC) requires a minimum of 2/0 AWG for copper wire or 4/0 AWG for aluminum or copper-clad wire size for a 200 Amp panel.

Most electricians will opt for a 3/0 copper or 250 kcmil aluminum wire. Here we use 3/0 AWG copper wire (with THHN insulation).Always check the NEC Table 310.12 ampacity table for your wire type before deciding.

Each 3/0 AWG THHN copper wire has an approximate diameter of 0.584, cross-sectional area of 0.2679 in². Total wire area (for 3 conductors) is 0.8037 in².

✅ Step 3: Check Conduit Fill Capacity (NEC Guidelines)

Let’s check what size conduit fits at least 0.8037 in² fill capacity at 40% fill:

👉 So, the minimum conduit size you need is: 1.5 or 1-½ inch PVC Schedule 40 Conduit

6. Tools and Resources to Simplify the Process

Choosing the right conduit size can seem complex, but fortunately, there are many helpful tools and resources available to make the job easier.

🧮 Online Conduit Fill Calculators: Several websites offer free calculators where you input wire type (e.g., THHN, THWN) or conduit types (e.g., EMT, PVC, RMC).

📊 Conduit Sizing Charts: Conduit fill tables provided by the National Electrical Code (NEC) show The maximum number of wires allowed for different conduit sizes.

🏭 Manufacturer’s Catalogs: Conduit manufacturers (like Ctube) provide detailed catalogs that include Inner and outer diameters & Wall thickness.

Using these tools together can save time, reduce errors, and make your installation process smoother and more efficient. Just as we make the calculation above.

7. Common Conduit Sizes and Their Applications

There are several standard conduit sizes ranging from 1/2 inch to 8 inches, commonly used in residential, commercial, and industrial electrical installations.

Conduit 1/2 pouce

Smallest Conduit Size: This is the smallest standard conduit size and is typically used for individual branch circuits or applications requiring only a few wires. It’s ideal for light residential use, such as wiring for lighting and small appliances.

Conduit de 3/4 pouces

Utilisation résidentielle : Le conduit de 3/4 de pouce est un choix populaire dans les environnements résidentiels. Il convient au passage de plusieurs fils ou câbles dans un seul conduit, ce qui le rend idéal pour les circuits domestiques standard et les petites applications commerciales.

Conduit de 1 pouce

Installations commerciales et résidentielles de plus grande taille : La taille du conduit de 1 pouce est souvent utilisée dans les environnements commerciaux et les installations résidentielles de plus grande taille. Il peut accueillir un plus grand nombre de fils et convient aux panneaux de service principaux, aux sous-panneaux et à d'autres applications nécessitant un câblage plus étendu.

Conduit de 1-1/4 pouces

High Voltage and Commercial Applications: This size is commonly used for higher voltage circuits and commercial installations where larger wires or cables need to be routed. It’s also suitable for feeder circuits in large residential buildings or small commercial establishments.

Conduit de 1-1/2 pouces

Grandes installations commerciales et industrielles : le conduit de 1-1/2 pouce est conçu pour les applications commerciales et industrielles importantes où une quantité importante de câblage est nécessaire. Il offre suffisamment d'espace pour des faisceaux de câbles plus grands, ce qui le rend adapté aux systèmes de câblage complexes.

Tailles supplémentaires (par exemple, 2 pouces, 3 pouces, 4 pouces, 5 pouces, 6 pouces, 7 pouces, 8 pouces)

Applications industrielles et robustes : les tailles de conduits de 2 pouces et plus sont généralement réservées aux environnements industriels ou aux applications intensives. Ces conduits plus grands sont essentiels pour loger de gros faisceaux de fils ou de câbles, tels que ceux utilisés dans les installations de fabrication, les centres de données et les grands bâtiments commerciaux. Ils fournissent la capacité nécessaire pour des systèmes électriques étendus et garantissent une installation et une maintenance faciles.

8. Conclusion

Selecting the correct conduit size is a crucial part of any safe and efficient electrical installation. From understanding the relationship between amperage, wire gauge (AWG), and conduit fill capacity, to using tools like NEC charts and online calculators, this guide has walked you through each step with practical tips and clear explanations.

By combining code compliance, basic calculations, and the right resources, you’ll be able to choose conduit sizes confidently—ensuring your electrical systems remain both safe and future-ready.

Ctube is a trusted manufacturer of electrical conduit solutions based in China, offering a wide range of PVC conduit and fittings tailored to modern electrical needs. Our products include: Schedule 40 & 80 Conduit, Type EB & DB Underground Conduit. Special series like Low Smoke Halogen-Free and Solar Conduits.

All products meet rigorous quality standards (UL, ASTM, IEC, AS/NZS), and are tested for fire resistance, UV protection, pressure tolerance, and durability in extreme environments.

FAQ

Q1: Do different conduit types affect the size I need?

Yes. EMT, PVC, RMC, and flexible conduit all have different inner diameters. Always refer to the specific type’s sizing chart when planning your installation.

Q2: Can I mix different wire sizes in the same conduit?

Yes, but it’s important to calculate the total fill area correctly. Each wire size has a different cross-sectional area, and all of them combined must not exceed the allowed fill percentage based on the number of conductors.

Q3: How long can a conduit run be without a pull box?

According to NEC, if there are more than 360° of bends (e.g., four 90° elbows) in a single conduit run, a pull box is required to avoid damage during wire pulling.

Comment choisir la taille du conduit pour les installations électriques En savoir plus "