How to Connect Flexible Conduit to an Electrical Box: A Step-by-Step Guide

1. Introduction

Flexible conduit is a versatile and essential component in modern electrical systems, offering protection and flexibility for wires in various applications. Unlike rigid conduit, flexible conduit can bend and adapt to challenging layouts, making it ideal for spaces with tight corners, irregular shapes, or frequent adjustments. Whether in residential basements, commercial offices, or industrial facilities, flexible conduit plays a critical role in safeguarding wires from mechanical damage, environmental hazards, and wear and tear. It is commonly crafted from materials like plastic, metal, or a combination of both, ensuring durability and adaptability across diverse environments.

Properly connecting flexible conduit to an electrical box is not just a matter of convenience; it is a fundamental step for ensuring the safety and efficiency of the entire electrical system. A secure connection prevents wires from being exposed to harmful conditions such as moisture, mechanical stress, or accidental dislodgment. Moreover, adhering to correct installation practices helps maintain compliance with electrical codes like the National Electrical Code (NEC), which is mandatory for safe and legally sound installations. Failing to meet these standards can lead to costly repairs, penalties, or even safety hazards.

This guide will introduce knowledge and techniques necessary to create a secure, code-compliant connection between flexible conduit and an electrical box.

2. Tools and Materials You’ll Need

To properly connect flexible conduit to an electrical box, a thorough understanding of the required tools and materials is essential. Each element serves a specific purpose, ensuring that the installation is secure, compliant with electrical codes, and capable of withstanding environmental or operational stresses.

2.1 Types of Flexible Conduit

Flexible conduit is the backbone of this connection process, providing a protective housing for electrical wires. Here are some commonly used flexible conduit. Choosing the right conduit type is critical to match the installation environment.

Liquid-Tight Flexible Conduit (LFMC): LFMC features a durable metal core wrapped in a moisture-resistant PVC jacket. It is specifically designed for outdoor or damp environments, such as HVAC systems, exterior lighting, or areas exposed to splashes and rain. Its waterproof design prevents moisture from reaching electrical wires, ensuring safety and longevity.

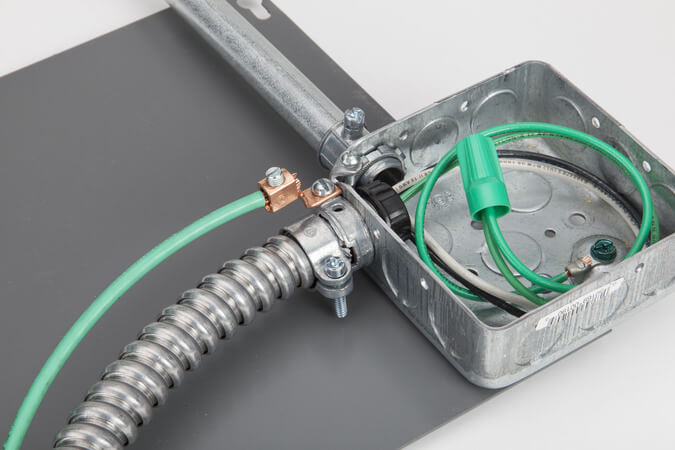

Metallic Flexible Conduit (FMC): Often referred to as “Greenfield” conduit, FMC consists of interlocked metal strips, providing a sturdy and flexible solution for indoor environments. It is ideal for industrial and commercial applications where mechanical protection is a priority, such as in equipment rooms or factories. FMC also allows for grounding when paired with metal boxes.

Non-Metallic Flexible Conduit (NMFC): Lightweight and corrosion-resistant, NMFC is a plastic-based conduit commonly made from PVC or polyethylene. It is perfect for residential installations and offers ease of handling and cutting. While cost-effective, NMFC is best suited for dry indoor spaces and may require additional protection in exposed environments. The widely used is the PVC corrugated conduit, so call electrical non-metallic tubing(ENT).

2.2 Types of Electrical Boxes

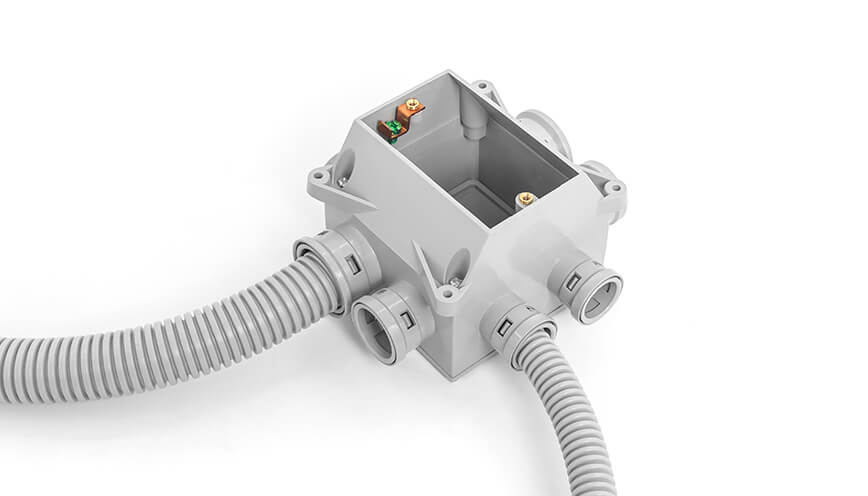

Electrical boxes serve as a junction point, housing wire connections and protecting them from external damage. The type of box chosen must align with the conduit type and the installation environment.

Junction Boxes: These large, multipurpose boxes are used to connect several wires, making them ideal for complex wiring systems. Junction boxes are frequently installed in walls, ceilings, or attics, and are compatible with various flexible conduit types.

Outlet Boxes: Smaller than junction boxes, outlet boxes are designed to house outlets, switches, or light fixtures. They are commonly used in residential and commercial buildings and can accommodate flexible conduit connections.

Weatherproof Boxes: Designed for outdoor or wet environments, these boxes are sealed to prevent water ingress. They pair perfectly with liquid-tight flexible conduits for use in areas like outdoor lighting, pool systems, or industrial washdown areas.

2.2.3 Metal vs. Plastic Boxes

Metal Boxes: Durable, heat-resistant, and conductive, metal boxes are often used in commercial and industrial settings. They provide a natural grounding path when used with metal conduits.

Plastic Boxes: Lightweight and non-conductive, plastic boxes are a cost-effective choice for residential use. They require separate grounding if used with metal conduits.

2.2.4 Box Sizing

Always consider the box size, ensuring it can comfortably house the number of wires and connectors. Overcrowding can lead to overheating and unsafe conditions.

2.3 Conduit Connectors

Conduit connectors are indispensable for attaching flexible conduit to an electrical box. They secure the conduit, ensure alignment, and maintain a safe enclosure for the wires.

Straight Connectors: These are the most basic type, designed to allow the conduit to enter the box in a straight path. They are ideal for installations where no directional changes are needed.

90-Degree Connectors: Used for making sharp turns without stressing the conduit or wires. These are essential in tight spaces or installations requiring a change in direction close to the box.

Strain Relief Connectors: These connectors are designed to secure the conduit while minimizing strain on the enclosed wires. They are particularly useful in areas subject to vibration or frequent movement.

Male and Female Connectors: These are used to join different conduit sections or to transition from conduit to box. Male connectors typically screw into female connectors for a secure fit.

Liquid-Tight Connectors: Specialized for use with liquid-tight flexible conduits, these connectors feature rubber gaskets or seals to prevent water ingress.

2.4 Hardware and Tools

A reliable connection requires more than just the conduit and connectors. The right hardware ensures stability and longevity:

Screws: Used to secure the connectors to the box. Choose corrosion-resistant screws, such as stainless steel, for outdoor or damp environments.

Nuts and Washers: Provide additional security, especially in metal boxes where a tight seal is critical to grounding and stability.

Locknuts and Bushings: Locknuts keep connectors firmly in place, while bushings prevent wires from rubbing against sharp edges.

Proper tools make the installation process smooth and efficient. Ensure all tools are of high quality and suited to the materials being used:

Wire Cutters/Strippers: Essential for preparing wires, these tools ensure clean cuts and proper insulation removal without damaging the wire core.

Screwdrivers: A set of screwdrivers (flathead, Phillips, or Torx) is necessary for securing connectors and box components. Opt for insulated handles for added safety when working near live wires.

Conduit Bender: While flexible conduit is naturally bendable, a conduit bender may be needed for precise angles, especially in metallic conduit applications.

Tape Measure: Accurate measurements ensure proper conduit lengths and reduce material waste. Always double-check measurements before cutting.

Utility Knife: Used for trimming excess material from non-metallic conduits or cleaning up rough edges.

Drill and Hole Saws: For installations requiring new openings in boxes or panels, these tools provide clean, precise cuts.

Level and Marker: A level ensures straight and professional-looking installations, while a marker helps plan conduit paths and mounting points.

3. Preparing the Conduit and Electrical Box

Proper preparation is essential for ensuring a safe, durable, and compliant electrical installation.

3.1 Measuring the Conduit

Accurate Measurement: Begin by measuring the exact length of conduit required to run from one electrical box to another, or from the box to an outlet, switch, or junction. Always use a measuring tape for accuracy, and ensure you’re measuring along the path where the conduit will be run, including any bends or turns.

Consider the Path: Flexible conduit can bend and be routed around obstacles, but sharp turns can damage the conduit or make it difficult to route. Make sure to plan for gradual bends. If you’re using conduit to route around corners or along walls, measure the total distance, adding a few extra inches for adjustments.

Account for Movement: Flexible conduit is often used in places where slight movement may occur (like walls or ceilings), so measure with some slack to accommodate this flexibility.

Allow for Bends: If you plan on bending the conduit, you need to account for the bend radius and add some extra length. Tight bends can strain the conduit and cables inside, leading to potential damage.

Bend Radius: Flexible conduit often has a minimum bend radius, which is the tightest curve it can safely make without damage. If you’re unsure, a general guideline is to maintain a bend radius at least three times the diameter of the conduit. For example, for a 1-inch conduit, the minimum bend radius would be approximately 3 inches.

3.2 Correct Cutting Techniques

To achieve a clean cut, use the correct cutting tool. For flexible conduit like ENT, conduit cutters (manual or power) are ideal because they make clean, precise cuts without deforming the conduit. Alternatively, a hack saw can also be used, but you’ll need to ensure the blade is fine-toothed to prevent fraying the edges.

Secure the Conduit: When cutting, it’s important to secure the conduit to avoid any movement that could lead to an uneven cut. Use a clamp, vice, or even a partner to hold the conduit in place while cutting. This step ensures a safer, more precise cut.

Cut Straight: A straight, even cut ensures that the conduit fits properly into the electrical box or connector without any gaps or misalignments. When cutting, keep the saw or cutter level, and always cut perpendicular to the length of the conduit.

Use a Guide: If you’re using a saw, a miter box or cutting jig can help guide your saw, ensuring a straight and square cut.

Pro Tip: After cutting, use a file or deburring tool to smooth out any sharp edges or burrs around the cut end of the conduit. This step is crucial to prevent the conduit from damaging the wires or making an improper fit when installed.

3.3 Preparing the Electrical Box

Inspect the Box: Electrical boxes are designed with pre-punched knockouts for various conduit sizes. Start by checking the box for a knockout that fits your conduit size. These knockouts are located on the sides or back of the box and can be easily removed to create an opening for the conduit.

Select the Right Knockout Size: Make sure that the knockout you select matches the diameter of the conduit. If the knockout is too large or too small, the conduit will not fit properly, leading to possible safety issues.

Clear Out Debris: Before making any connections, thoroughly inspect and clean the electrical box. Electrical boxes can collect dust, dirt, old wire insulation, and other debris that could obstruct a proper connection. Use a dry cloth to wipe down the box, and check for any old wires or metal fragments that could pose a hazard during installation.

Check for Obstructions: Ensure that there are no obstructions inside the box that could interfere with the conduit fitting or prevent it from sitting properly against the box wall. Any obstacles can cause issues when trying to secure the conduit, resulting in an unsafe connection.

Final Check: Before proceeding to install the conduit and make the connections, take a moment to double-check all preparations. Ensure that the lengths of the conduit are accurate, the sheaths are properly stripped, and the electrical box is clean and ready for connection. A final check before installation helps ensure everything goes smoothly, reducing the risk of mistakes or needing to redo the work later.

4. Step-by-Step Guide to Connecting the Flexible Conduit

Connecting flexible conduit to an electrical box is a process that requires careful attention to detail. A secure connection ensures both the safety and functionality of the electrical system, protecting the wires inside and preventing wear or accidental disconnections. Below is a comprehensive step-by-step guide on how to connect flexible conduit to an electrical box, ensuring a successful and safe installation.

Step 1: Position the Conduit and Box

Start by positioning the electrical box and flexible conduit where they will be connected. Ensure that both the box and the conduit are securely positioned in relation to each other to minimize strain on the wiring and connectors.

Align the Conduit with the Box: Before making any physical connection, take a moment to ensure that the conduit will line up properly with the electrical box’s knockout. This will help avoid unnecessary bending or twisting, which can put stress on both the conduit and the internal wiring.

Allow Space for Bends (If Necessary): If the flexible conduit needs to be bent to make a connection, allow for the appropriate amount of space. Flexible conduit is easy to bend by hand, but it’s important not to over-bend it, as this can damage the wires inside.

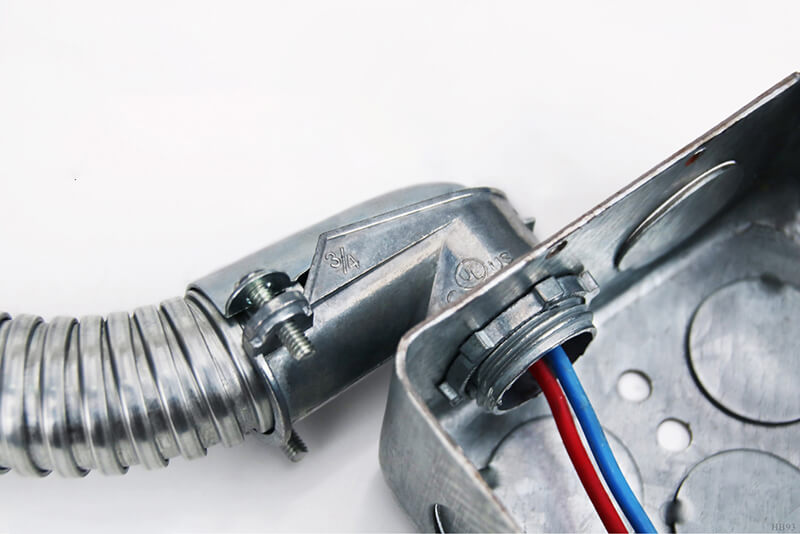

Step 2: Attach the Conduit Connector

The conduit connector is the part that will physically join the flexible conduit to the electrical box. Choose a connector that matches the size of the conduit and fits the knockout on the electrical box. There are various types of conduit connectors, such as straight, 90-degree, strain relief, and male/female connectors, depending on the requirements of your installation.

Insert the Conduit into the Connector: Slide the end of the flexible conduit into the connector, ensuring that the wire inside is not damaged. Most connectors will have a grommet or a compression seal to protect the wire and prevent abrasion.

Ensure the Proper Fit: The conduit should fit snugly inside the connector. If the connector has a threaded end (such as a compression-type connector), ensure that the threads engage properly for a secure connection.

Strain Relief (If Required): For installations where the conduit may be subject to physical strain, or where it needs extra support, use a strain relief connector. This type of connector prevents the conduit from being pulled out of the box under tension.

Step 3: Secure the Connector to the Electrical Box

Once the conduit is inserted into the connector, it’s time to secure the connector to the electrical box. This step is critical for ensuring the conduit is firmly attached and will not come loose over time, which could lead to safety hazards.

Tighten the Connector: Use a screwdriver to tighten any screws or bolts that hold the connector in place. Make sure the connector is flush against the box, with no gaps between the box and the conduit. This will ensure a solid, stable connection.

Use Locknuts (If Necessary): Some connectors, especially those used with metallic conduit, may require locknuts to secure them. Locknuts are placed on the inside of the box and tightened to hold the connector in place. Be sure to tighten the locknut securely, but avoid over-tightening, as this could damage the box or connector threads.

Ensure a Secure Seal: If using a liquid-tight connector, check to see if it has a rubber seal that helps prevent moisture from entering the box. This is especially important in outdoor or damp environments.

Step 4: Tighten the Conduit

After the connector is securely fastened to the box, tighten the flexible conduit itself to ensure it is firmly seated in the connector. This step is essential for ensuring the integrity of the conduit and protecting the wires from being exposed or pulled out.

Push the Conduit Into the Connector: For certain types of connectors, you will need to push the flexible conduit further into the connector until it is fully seated. If the connector has a compression or locking mechanism, tighten it to securely hold the conduit in place.

Check for Movement: Once the conduit is tightened, gently tug on it to ensure it’s firmly connected. There should be no movement between the conduit and the box. If there is, recheck the connection and ensure that all screws, bolts, or locking mechanisms are properly tightened.

Step 5: Secure the Wires Inside the Conduit

Now that the conduit is securely connected to the box, the next step is to ensure that the wires inside the conduit are properly secured. This is important for preventing any wires from coming loose or creating a safety hazard.

Check the Wire Length: Ensure that the wires inside the conduit are long enough to reach their intended terminals or connectors without being stretched tight. If necessary, trim any excess wire to avoid tangling or excess slack.

Strip and Connect the Wires: If you haven’t already done so, strip the wires as needed and connect them to the appropriate terminals inside the electrical box. Ensure that the wire connections are tight and secure, with no exposed wire.

Secure the Wires: If the electrical box has a wire clamp or strain relief for securing wires, use it to hold the wires in place. This will prevent the wires from moving within the conduit and keep them protected from damage.

Step 6: Final Checks

After everything is connected, it’s essential to perform a final check to ensure the installation is both safe and compliant with electrical codes.

Check for Proper Tightness: Double-check that all connections, including the conduit connector, conduit, and electrical box screws, are securely tightened. Loose connections can lead to electrical shorts, increased resistance, or even fire hazards.

Verify Grounding Connections: Ensure that any grounding wire or component is properly connected to the grounding terminal in the electrical box.

Inspect for Exposed Wires: Make sure no wire is exposed beyond the electrical box or the connector. Exposed wires can create shock hazards, so they should be properly secured and insulated.

Step 7: Test the Connection

Once the connection is made and everything is tightened, it’s important to test the installation before finalizing everything.

Power On the System: If safe to do so, power on the electrical system to ensure the connection is functioning properly. Check that there are no issues with the wiring, such as short circuits, excessive heat, or tripped breakers.

Look for Issues: Inspect the area around the conduit and electrical box for any signs of overheating, sparks, or unusual noises. These could indicate a problem with the connection that needs to be addressed before continuing.

5. Compliance and Safety Standards

When working with electrical conduit installations, ensuring compliance with safety standards and codes is critical for both the safety of the installation and the protection of the property. Several standards and certifications are in place to guide professionals in selecting and installing the right materials and ensuring that the entire system operates effectively and safely. These standards include the National Electrical Code (NEC), UL and CSA certifications, and adherence to local building codes.

5.1 NEC Code Requirements: Key Standards for Conduit Installations

The National Electrical Code (NEC) is the primary standard for the safe installation of electrical wiring and equipment in the United States. When it comes to conduit installations, the NEC provides clear guidelines that help professionals avoid dangerous mistakes and ensure long-lasting, safe systems. The NEC covers aspects such as the types of conduit to use, their size, and the methods of installation.

In the following, we make some reference on the requirements for junction box installation fo readers.

5.1.1 NEC 314.28: Guidelines for Junction Box Material

This section sets forth the standards for the materials used to construct junction boxes.

Junction boxes must be constructed of materials that are compatible with the environment and conditions where they are installed. This includes fire resistance, durability, and protection against mechanical impact.

Materials commonly used for junction boxes include metal (steel, aluminum) or non-metallic materials (PVC, fiberglass), depending on environmental conditions such as exposure to moisture or chemicals.

Boxes must also meet specific standards for corrosion resistance if used in environments like coastal areas where saltwater can cause corrosion.

If the junction box is to be used in hazardous locations (explosive or flammable environments), the materials must comply with the specific hazardous location requirements (see NEC 370-29).

The box material must be able to withstand the temperature ranges and stresses expected in the environment.

5.1.2 NEC 314.16: Volume Size of the Junction Box

This section provides guidance on the proper volume (size) of junction boxes to ensure safe operation and prevent overheating.

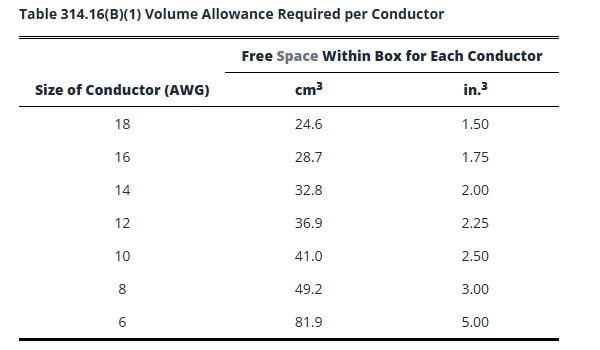

Box Fill Calculations: The size of the junction box must be large enough to accommodate all the conductors, devices, and fittings it houses without overcrowding.

The fill calculation involves the conductor size, the number of conductors, devices (like switches or receptacles), clamps, and grounding conductors.

Box Volume: The required volume depends on several factors.

For conductors: Each conductor (live, neutral, or ground) contributes a specific number of cubic inches based on its gauge.

For devices: Switches, outlets, and similar devices require a certain amount of space within the box.

Clamps and connectors: These components also add to the fill calculation.

Box Fill Formula: The NEC provides a table (NEC Table 314.16(B)) that assigns cubic inch values for each item. The total fill must not exceed the volume rating of the box to avoid overheating, electrical faults, or difficulty in making proper connections.

5.1.3 NEC 370-29: Junction Boxes for Hazardous Locations

This section outlines requirements for junction boxes in hazardous locations, where there is a risk of explosion or fire due to flammable gases, vapors, or dust.

Explosion-Proof and Dust-Ignition-Proof Boxes: Junction boxes used in hazardous locations must be rated as explosion-proof (Class I, Division 1 or 2) or dust-ignition-proof (Class II, Division 1 or 2). These boxes must prevent ignition from electrical equipment sparks, arcs, or heat.

Sealing and Gasketing: The boxes must have seals and gaskets that prevent the entry of flammable materials, dust, or liquids that could ignite.

Cover Design: The covers must be tightly sealed and able to withstand high-pressure releases without allowing hazardous substances to escape.

Material Considerations: The materials of the box must be designed to prevent corrosion and degradation in environments with hazardous chemicals, gases, or extreme temperatures.

5.1.4 NEC 314.29: Junction Boxes for Non-Hazardous Locations

This section applies to junction boxes in non-hazardous locations where the risk of explosion or fire is minimal.

General Safety: The box should meet general safety standards, providing enough space for safe electrical connections and preventing overheating.

Weatherproofing: In areas with exposure to moisture, dust, or dirt (such as outdoor installations), the box must be weatherproof and rated for the environmental conditions. For example, outdoor boxes need to be rated for wet or damp locations (e.g., NEMA 3R, 4, or 4X).

Code Compliance: Non-hazardous junction boxes must still comply with all other applicable sections of the NEC, including those related to grounding (NEC 250.110), working space (NEC 110.26), and box fill calculations (NEC 314.16).

5.1.5 NEC 250.110: Guidelines for Junction Box Grounding

This section ensures that electrical systems are properly grounded to prevent shock hazards and electrical fires.

Grounding Connections: Junction boxes must have a proper grounding connection. This includes a bonding jumper or ground wire that connects the box to the grounding system of the building or structure.

Metallic Boxes: For metallic junction boxes, the box itself is used as a grounding conductor. A grounding screw or terminal must be provided inside the box to connect the ground wire.

Non-Metallic Boxes: Non-metallic junction boxes require an external ground wire to be connected to a grounding terminal or ground screw. The plastic material of the box does not conduct electricity, so an independent ground conductor must be run to the box.

Integrity of Grounding System: The grounding system must be maintained throughout the electrical installation to ensure the safe operation of the electrical system and prevent electric shock.

5.1.6 NEC 110.26: Guidelines for Clearance

This section establishes the required working space around electrical equipment, including junction boxes, to ensure safety during installation, maintenance, and emergency procedures.

Front Clearance: A minimum working space must be provided in front of electrical panels and junction boxes to allow safe operation and maintenance. Typically, this space must be at least 30 inches wide and extend from the floor to the ceiling, depending on the voltage and amperage.

Depth of Clearance: The minimum depth of the working space depends on the voltage (e.g., for 600 volts or less, the space must be at least 3 feet deep). Higher voltages require greater clearances.

Height Clearance: For safe access to the junction box, the top of the box or electrical panel should be installed with adequate height clearance, typically at least 6.5 feet above the floor.

Obstructions: There must be no obstructions in the working space that could hinder the installation or servicing of the junction box, and all access points must remain clear.

5.2 UL and CSA Certifications: Importance of Certified Materials and Connectors

UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certifications play a crucial role in maintaining safety in electrical conduit installations. These organizations are responsible for testing and certifying electrical products and components, ensuring that they meet stringent safety standards.

For materials like electrical conduits, connectors, and junction boxes, UL certification ensures that the products have been tested for fire resistance, durability, and the ability to withstand extreme conditions. Conduits that carry the UL label indicate they have met the necessary safety and performance standards for a variety of environments. Similarly, CSA certification confirms that products meet Canadian safety standards, ensuring they are safe for use in electrical systems across Canada.

Using certified materials and connectors is crucial because it minimizes the risk of electrical faults or fires caused by defective components. When products carry these certifications, installers and building owners can be confident that the materials have undergone rigorous testing and are suitable for their intended use. Additionally, certified components ensure compliance with the NEC and other safety standards, making it easier to pass inspections and meet legal requirements.

6. Conclusion

Connecting flexible conduit to an electrical box may seem like a straightforward task, but it plays a crucial role in ensuring the safety, efficiency, and durability of an electrical system. Proper installation protects electrical wires from damage, reduces the risk of electrical faults, and ensures compliance with industry standards and regulations.

Ctube is a trusted provider of high-quality flexible conduits and electrical accessories designed to meet diverse project requirements. Our flexible conduits are manufactured to the highest standards and certified by UL, CSA, and AS/NZS 2053, ensuring exceptional performance, durability, and compliance with international safety and quality standards.

In addition to flexible conduits, we offer a comprehensive range of electrical boxes and related accessories, such as cup combs, tailored to various applications. These products are engineered to provide reliable solutions for residential, commercial, and industrial projects, making them ideal for demanding environments.

At Ctube, we pride ourselves on offering customized solutions to meet the specific needs of our clients. Whether your project requires a specialized conduit type or a complete set of electrical accessories, our team is ready to assist. We combine innovation, quality, and excellent customer service to help you achieve your project goals efficiently and effectively.

Thanks for your reading, and good luck with your projects.

FAQs

1. Can flexible conduit be used outdoors?

Yes, flexible conduit can be used outdoors, but it is essential to choose the right type for outdoor applications. When using flexible conduit outdoors, ensure it is UV-resistant and compatible with the environmental conditions, such as extreme temperatures or heavy rainfall. Always check the manufacturer’s specifications and local building codes for outdoor use.

2. How do I know if I’m using the right size connector for my conduit?

Choosing the correct size connector involves matching the connector to the diameter of your flexible conduit. Conduits are typically measured by their nominal size (e.g., ½ inch, ¾ inch), which should align with the size marked on the connector. Additionally, ensure the connector is compatible with the type of conduit you’re using (e.g., liquid-tight or metallic). Properly sized connectors ensure a secure fit, prevent movement, and maintain the integrity of the system.

3. What if my conduit is too short to reach the electrical box?

If your flexible conduit is too short, you have two options:

Use a Conduit Coupler: This accessory allows you to connect two pieces of conduit securely, extending its length. Be sure the coupler matches the conduit type and size.

Replace with a Longer Conduit: If possible, replace the shorter section with a longer piece to eliminate potential weak points.

Ensure that any connections are properly sealed, especially in environments where moisture or debris could enter the system. Additionally, avoid stretching or over-bending the conduit as this can damage the wiring or compromise the installation.

How to Connect Flexible Conduit to an Electrical Box: A Step-by-Step Guide Read More »