How Temperature Affects PVC Electrical Conduit Pipes

1. Introduction

1.1 What are PVC Electrical Conduit Pipes?

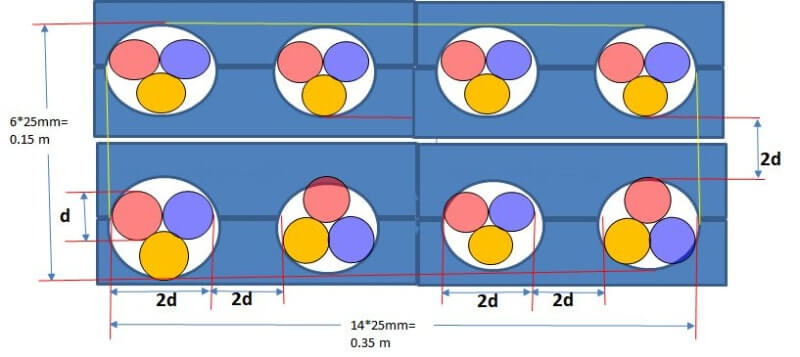

PVC (Polyvinyl Chloride) electrical conduit pipes are rigid or flexible pipes used to protect and route electrical wiring in both residential and commercial buildings. These pipes act as protective channels for electrical cables, shielding them from mechanical damage, moisture, chemicals, and other environmental factors. The primary purpose of PVC conduit is to ensure the safe transport of electrical wiring while offering an easy-to-install, low-maintenance, and durable solution for wiring systems.

PVC conduit pipes have become a popular choice for electrical installations due to their excellent combination of properties. They are highly durable, resistant to corrosion, and can withstand impacts and pressure. PVC conduits are also affordable and versatile, available in a range of sizes and configurations, making them suitable for various applications—from residential homes to large industrial facilities.

1.2 Why is Temperature a Key Factor?

Temperature plays a crucial role in the performance and longevity of PVC electrical conduit pipes. The physical and mechanical properties of PVC, such as its flexibility, strength, and resistance to impact, are all influenced by temperature variations. When the temperature fluctuates, PVC conduit pipes may expand or contract, affecting their ability to maintain a secure fit and proper insulation for electrical cables.

At higher temperatures, PVC may become more pliable, potentially leading to deformation or warping. On the other hand, extreme cold temperatures can make the material more brittle and prone to cracking. Therefore, understanding how temperature affects PVC conduit is essential to ensure that the installation remains safe, effective, and long-lasting, particularly in regions subject to temperature extremes.

Properly managing temperature effects during installation and use of PVC conduit is key to ensuring the safety and reliability of the electrical system. By selecting the right type of PVC conduit and considering temperature conditions in the installation environment, you can prevent damage to the conduit and the wiring inside it, ensuring a smooth and long-lasting electrical setup.

2. Overview of PVC’s Thermoplastic Nature

2.1 Thermoplastic Behavior and Molecular Structure

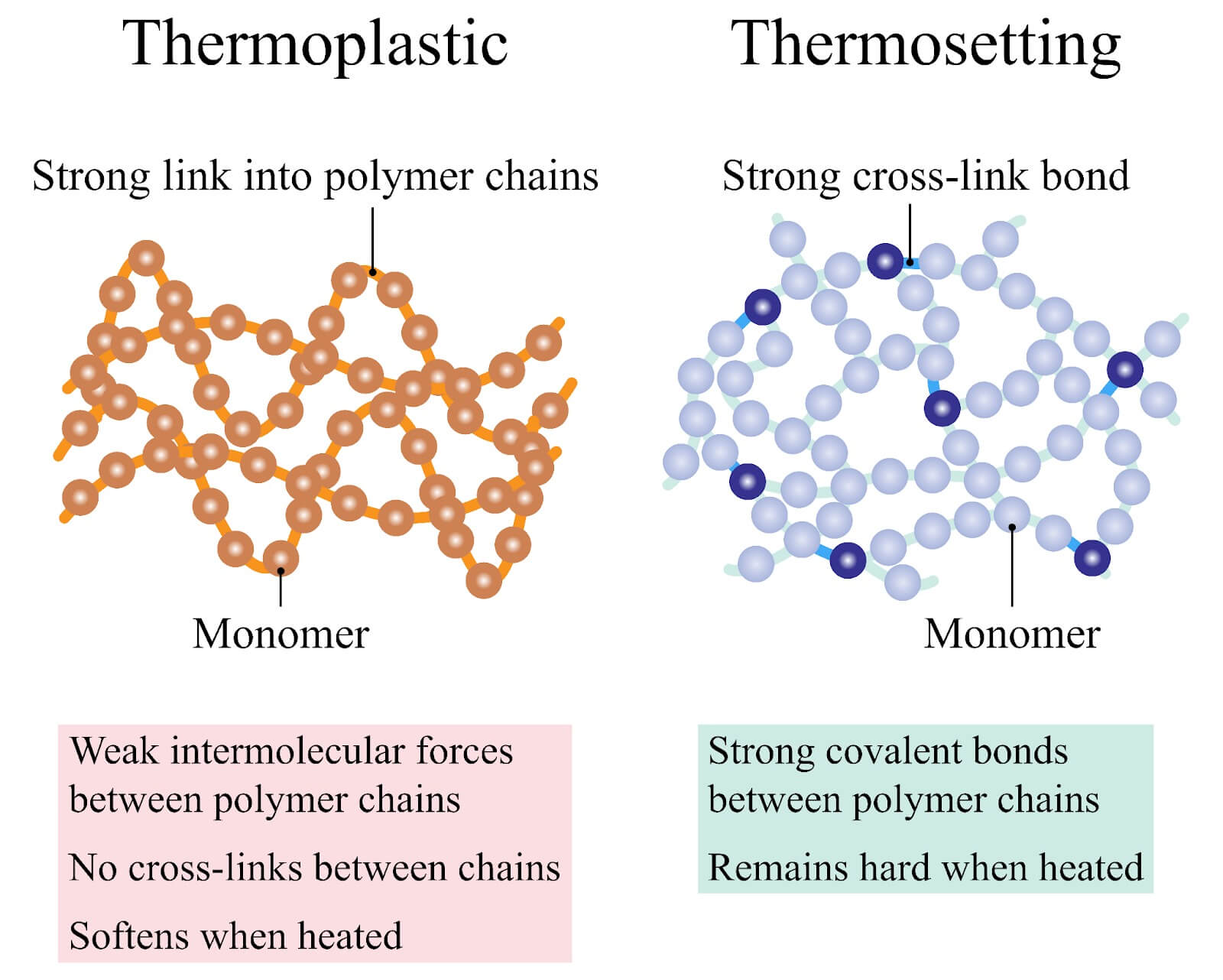

PVC (Polyvinyl Chloride) is a thermoplastic material, meaning it softens and becomes moldable when heated and solidifies upon cooling. This reversible behavior is due to its molecular structure, which comprises long polymer chains held together by intermolecular forces weaker than the covalent bonds in thermosetting plastics. These characteristics allow PVC to be reshaped multiple times through processes such as extrusion, molding, and welding, making it a versatile choice for manufacturing electrical conduit pipes.

When heated, the polymer chains gain energy and move more freely, causing PVC to soften and become flexible. This property is beneficial during installation, where bending or shaping the conduit is often required. Upon cooling, the chains contract, solidifying the PVC into a rigid and stable form suitable for providing structural support.

2.2 Sensitivity to Temperature Variations

PVC’s response to temperature changes has practical implications for its performance in electrical installations.

- At higher temperatures, PVC becomes softer and more pliable. While this flexibility is useful for certain applications, excessive heat can lead to deformation or a reduction in mechanical strength.

- At lower temperatures, PVC hardens and becomes more brittle. This rigidity can improve structural stability but increases the risk of cracking or breaking under sudden impacts or stress.

These temperature-sensitive properties make proper handling and installation critical, particularly in environments with extreme heat or cold. Understanding and managing these thermal behaviors ensures the effective and reliable use of PVC conduits in diverse applications.

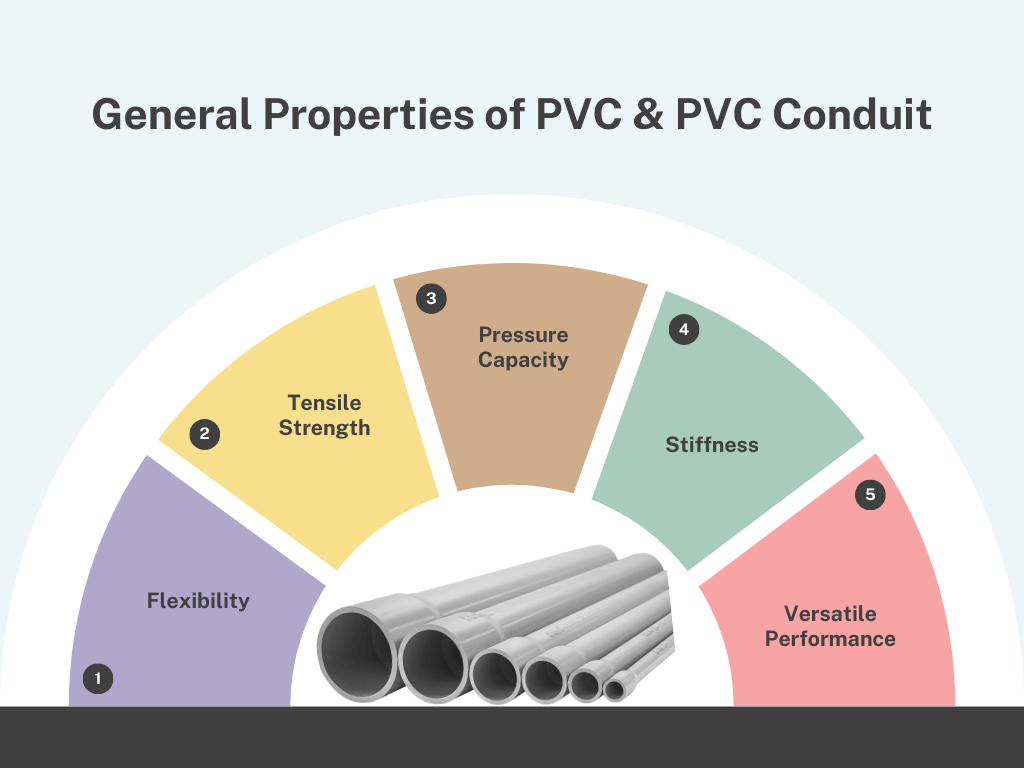

2.3 General Properties of PVC & PVC Conduit

At standard conditions, typically around 73°F (23°C), PVC exhibits a balance of physical properties that make it a popular choice for electrical conduit applications:

- Flexibility: At moderate temperatures, PVC is sufficiently flexible, allowing it to bend without breaking. This flexibility is ideal for installation in tight spaces or around corners, where the conduit needs to be easily shaped to fit the required path.

- Tensile Strength: PVC has a high tensile strength, meaning it can withstand significant pulling forces without breaking or stretching. This property ensures that PVC conduit pipes maintain their structural integrity under tension during installation and use.

- Pressure Capacity: PVC conduits can withstand high internal pressure, making them suitable for applications where electrical cables may be subject to pressure. This resistance to pressure also adds to the conduit’s durability and overall lifespan.

- Stiffness: PVC is relatively stiff at standard temperatures, which helps it retain its shape and resist deformation under normal conditions. This stiffness is particularly important for maintaining the conduit’s protective function, as it ensures that the pipe does not collapse or become misshapen over time.

While PVC performs well under standard conditions, understanding how it behaves under varying temperature conditions is essential to ensure the long-term reliability and safety of PVC electrical conduit pipes in real-world applications.

3. Effects of High Temperatures on PVC Pipes

3.1 Increased Flexibility

When PVC pipes are exposed to high temperatures, they undergo a softening process that reduces their stiffness and enhances their flexibility. This occurs because the polymer chains that make up PVC gain more energy at higher temperatures, allowing them to move more freely. As a result, the material becomes more pliable, making the pipe easier to bend and shape. This increased flexibility can be advantageous in certain situations where pipes need to be adjusted to fit around obstacles or when bending is necessary for the installation.

Benefits: The added flexibility at high temperatures is particularly useful in outdoor applications, where PVC pipes need to be bent to navigate around corners or through tight spaces. For example, installing PVC conduit in a hot climate may make it easier to shape the pipe without using additional bending tools or equipment. This flexibility allows for more efficient and quicker installations, especially when adjustments or reconfigurations are needed.

Challenges: However, while flexibility can make installation easier, it also introduces some long-term risks. In hot climates, where temperatures may remain elevated for extended periods, the increased pliability of the PVC can cause the pipes to sag or warp. Over time, this deformation can lead to several issues, including:

- Sagging: The conduit may lose its intended shape and begin to droop or bend under its own weight or the weight of the electrical cables inside. This sagging can cause the conduit to pull away from its mounting points, creating gaps or weak points in the system.

- Warping: Warped pipes may not align properly with fittings, compromising the seal or connection and potentially leading to leaks, damage to the wiring, or even electrical hazards.

To mitigate these risks, installers should consider using additional support brackets, spacers, or hangers when installing PVC conduit in hot environments. These measures help keep the conduit securely in place and maintain its structural integrity, even as the temperature rises.

3.2 Reduced Pressure Capacity

As the temperature increases, the ability of PVC pipes to withstand internal pressure decreases. This reduction in pressure resistance occurs because the material becomes more flexible and less rigid at higher temperatures, making it unable to hold up under the same pressure as it would at lower temperatures.

In order to better understanding, we provide some data of plumbing or fluid pipe in the followings.

- Pressure Capacity Reduction: The pressure capacity of PVC pipes diminishes as the temperature rises. For instance, a Schedule 40 PVC pipe rated for 450 PSI at 73°F may only be rated for about 200 PSI at 140°F. This illustrates a drastic reduction in pressure handling capability with increasing temperature.

- Temperature Effects: The baseline reference for PVC’s pressure ratings is typically around 22°C (73°F). As temperatures exceed this baseline, the material becomes less rigid and more prone to deformation under pressure. For example, at 43°C, the pressure capacity can drop significantly, necessitating careful consideration in applications involving hot fluids.

- Derating Factors: For instance, a formula can be used to adjust the pressure rating based on temperature increases. At 60°C, a common derating factor might reduce the allowable pressure capacity to 70% of its original rating at 22°C.

- Practical Implications: This reduction in pressure capacity is crucial for applications involving hot water or other heated fluids, as exceeding the rated pressure at higher temperatures can lead to pipe failures such as bursts or leaks.

This change happens because the increased molecular mobility at higher temperatures allows the polymer chains to shift more easily, making the pipe more prone to deformation under pressure. The material is less able to resist the internal forces acting on it when the temperature rises, leading to a decrease in its overall pressure capacity.

Derating Factors: To account for these changes in pressure capacity, manufacturers use derating factors that adjust the pipe’s pressure rating based on its operating temperature. These factors provide a guideline for determining the safe operating pressure at different temperatures. For instance, if the temperature of the environment or the fluid inside the conduit increases, the pressure rating must be adjusted downward to ensure the pipe can safely handle the pressure without failure. Engineers and installers should carefully consult the manufacturer’s pressure charts to apply the correct derating factors and select the appropriate pipe for the specific temperature conditions.

Importance in High-Pressure Systems: In applications where high-pressure systems are involved, such as in industrial or hydraulic installations, it’s crucial to consider the effect of temperature on PVC pipes. Failure to apply derating factors in these conditions can result in catastrophic pipe failure, leading to leaks, system damage, or even safety hazards.

3.3 Thermal Expansion

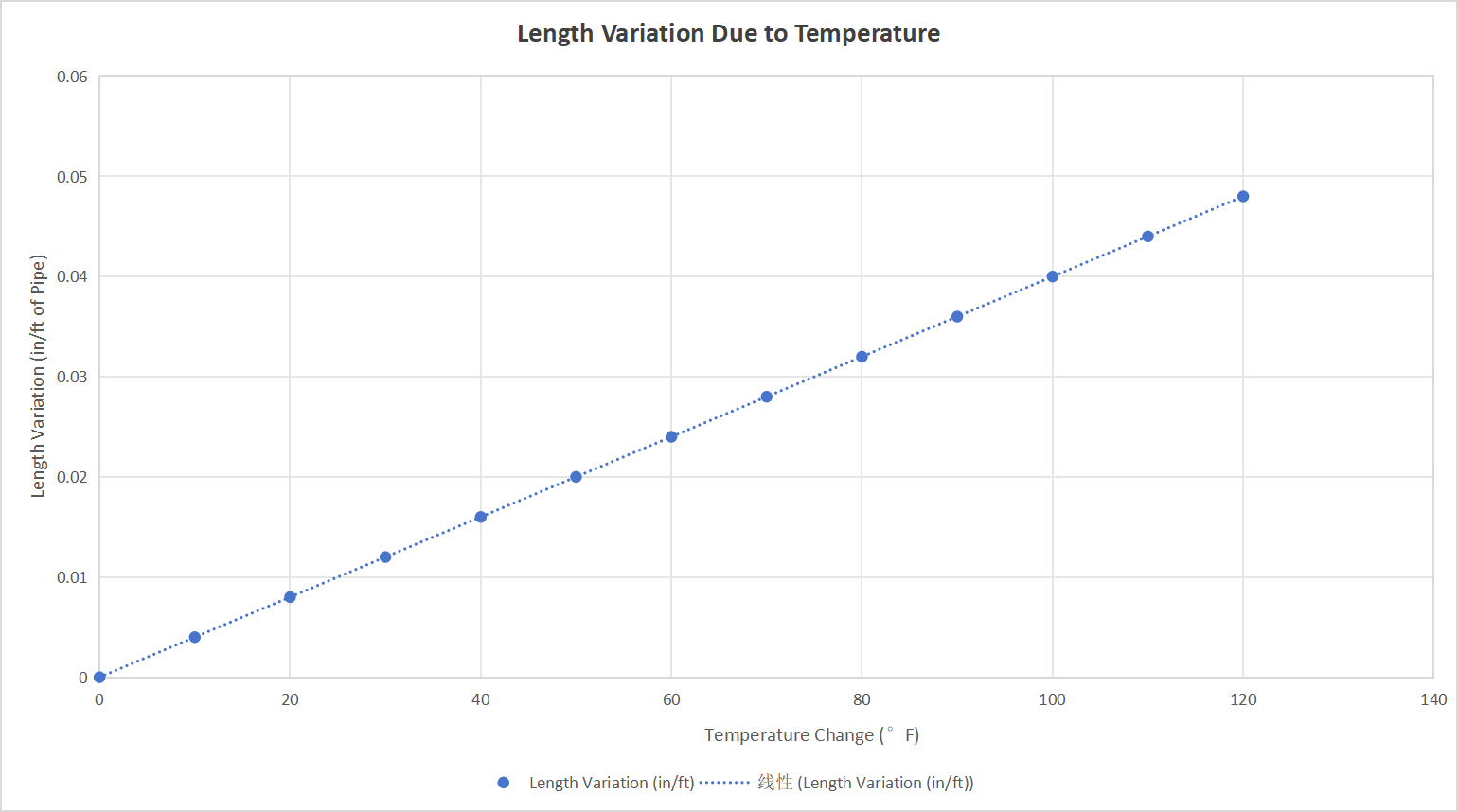

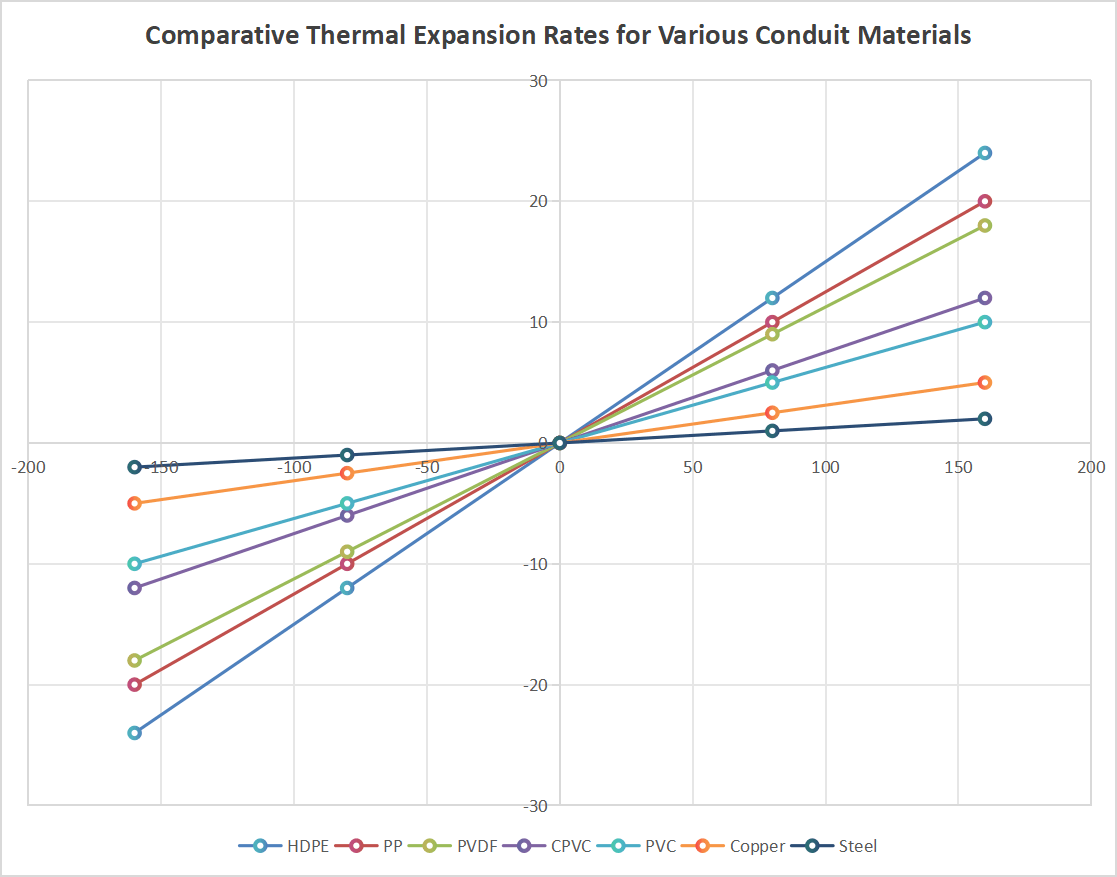

The coefficient of thermal expansion for PVC is approximately 50.4*10-6m/m/℃ or 28*10-6 in/in/℉. This means that for every degree Celsius increase in temperature, a meter of PVC will expand by about 50.4 micrometers.

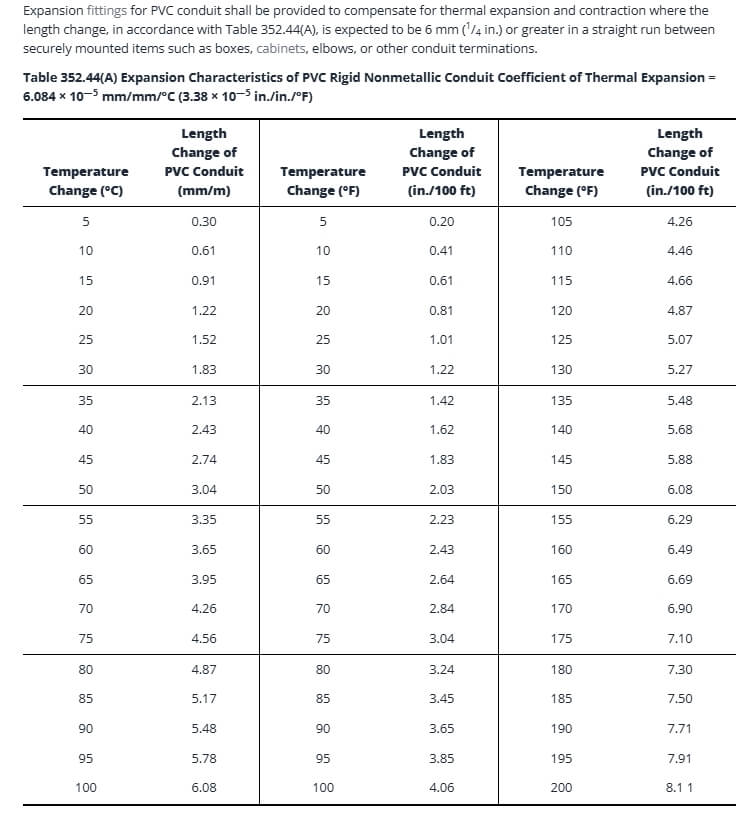

From Texas SFM Electrical Code 2023 > 3 Wiring Methods and Materials > 352 Rigid Polyvinyl Chloride Conduit (Pvc) >352.44 Expansion Fittings >(A) Thermal Expansion and Contraction

- Length Change Calculation: A practical rule of thumb states that PVC will expand approximately 7 mm for every 10 meters of pipe for every 10°C change in temperature. For example, if a 150-meter line of PVC pipe is subjected to a temperature drop from 28°C to 18°C (a difference of 10°C), it would contract by about 0.7 mm per meter, resulting in a total contraction of 105 mm across the entire length.

- Comparison with Other Materials: The thermal expansion coefficient of PVC is notably higher than that of metals like carbon steel, which has a coefficient around 11.7*10-6m/m/℃. This highlights the greater sensitivity of PVC to temperature changes compared to traditional piping materials.

*The content above is organized based on information from the website and is provided for reference only. Please refer to the actual experimental data for accurate details.

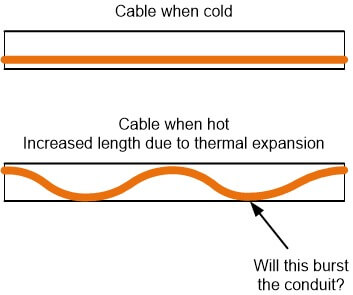

System Alignment: When PVC pipes expand due to high temperatures, they can cause shifts or misalignments in the entire conduit system. These shifts may affect the alignment of the pipes, potentially leading to stress at the joints or connections. If the system is not properly installed with allowances for thermal expansion, it can result in issues such as:

- Joint Failure: PVC joints and fittings are designed to fit tightly, but when the pipe expands, the pressure on the joints can cause them to loosen or even crack. Over time, this can lead to leaks or a compromised seal, allowing moisture, debris, or contaminants to enter the system.

- Deformation of Fittings: PVC fittings, such as elbows, tees, or connectors, may also become deformed or displaced as the pipes expand. This misalignment can lead to a less secure connection, increasing the risk of failure.

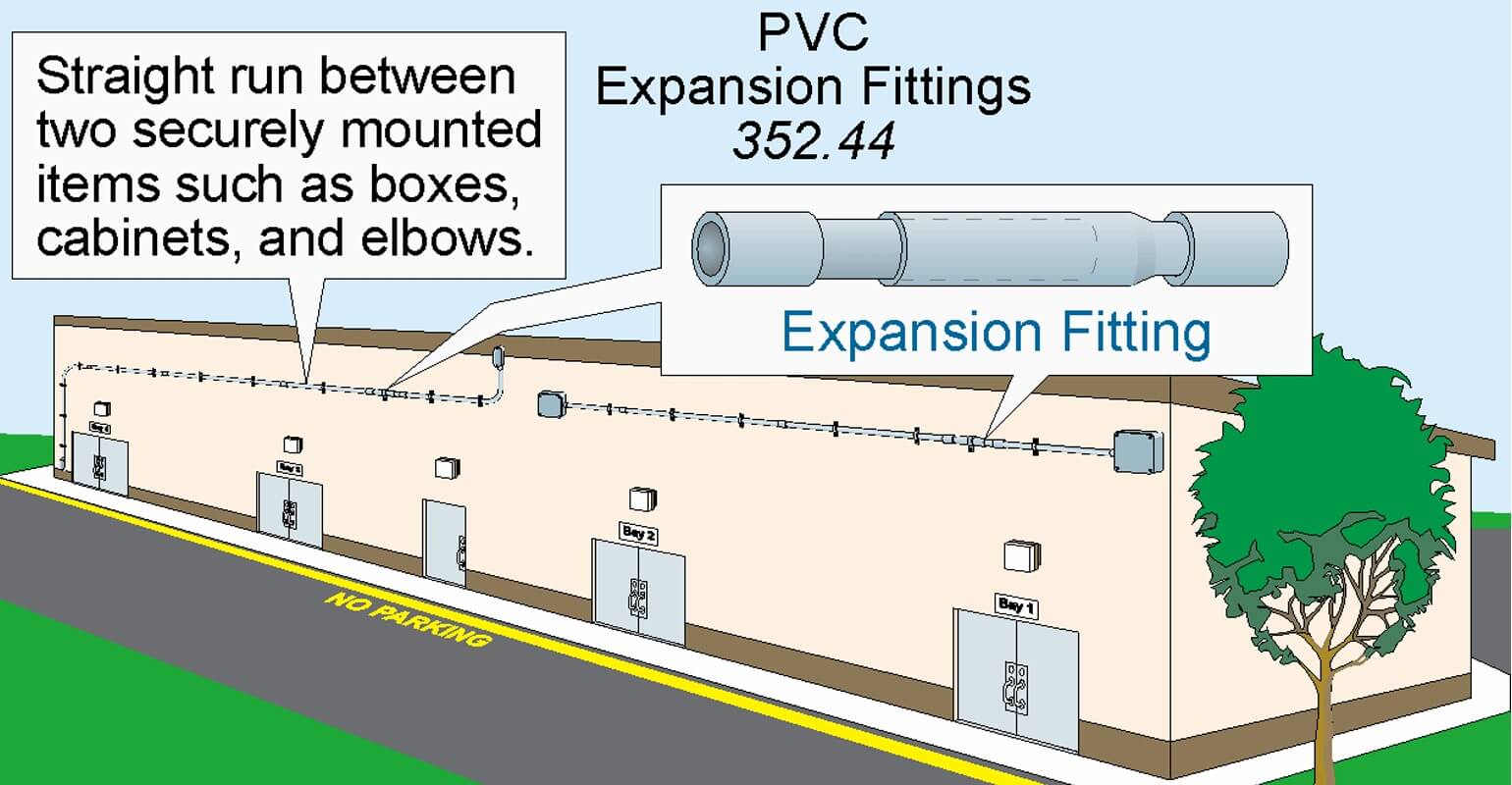

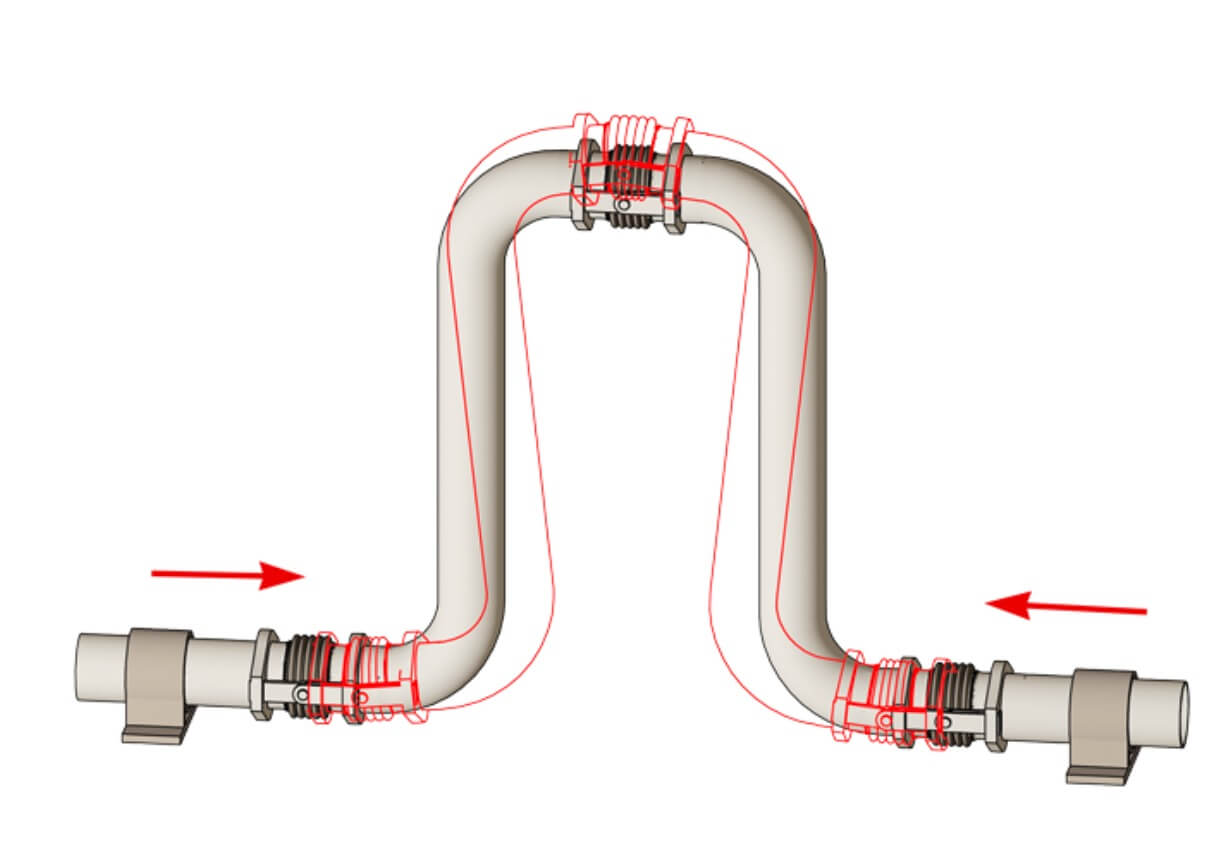

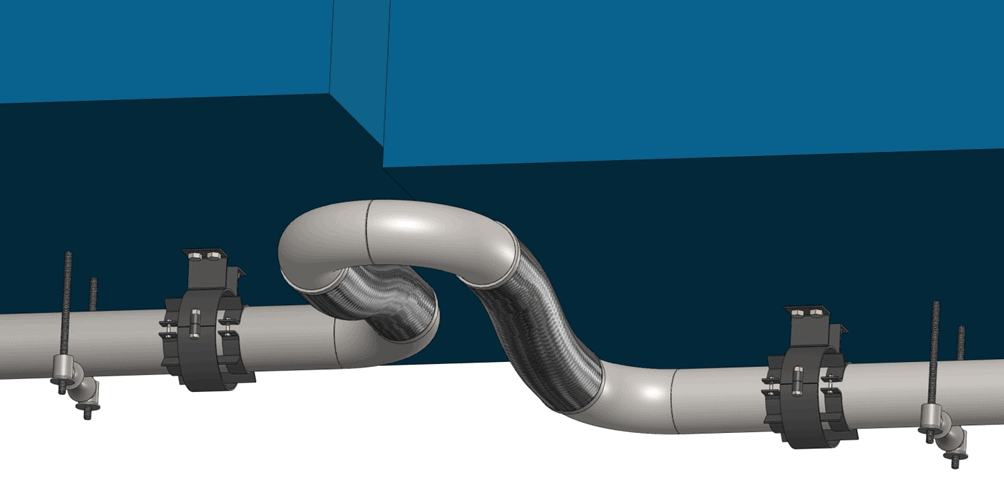

Expansion and Contraction Considerations: In installations with long conduit runs, such as underground or outdoor systems, thermal expansion and contraction become more pronounced. To accommodate this natural movement of the material, it’s important to:

- Use expansion fittings or compensators, which are designed to absorb the expansion and contraction of PVC pipes, preventing stress on the joints and ensuring a secure system.

- Leave slack in the system by installing the pipes loosely and allowing room for them to expand and contract without causing damage.

- Consider the temperature fluctuations the conduit will experience over time and plan for the most extreme conditions, such as those during the summer heat or winter cold.

Potential Long-Term Effects: Over time, repeated thermal expansion and contraction cycles can weaken the joints and fittings, potentially leading to cracks or leaks. If not managed properly, this movement can lead to premature wear and failure of the conduit system. Therefore, ensuring proper installation with thermal expansion allowances is essential for the longevity of the system.

4. Effects of Low Temperatures on PVC Pipes

4.1 Increased Rigidity

At low temperatures, PVC becomes significantly stiffer and more rigid, which is primarily due to the reduced molecular motion within the polymer structure. As the temperature decreases, the molecular chains in the PVC material slow down and become less flexible. This increase in stiffness enhances the pipe’s ability to resist deformation under load, making it less likely to bend or collapse when subjected to external pressure or weight.

Benefits: The increased rigidity of PVC at low temperatures is especially advantageous in applications where the conduit is exposed to physical stress or pressure. For instance, in colder climates or outdoor installations where the conduit is buried underground, the rigidity helps maintain the conduit’s shape and protects the electrical wiring inside from external forces. This resistance to bending is beneficial in preventing the conduit from sagging or becoming misshapen over time.

Considerations: However, while rigidity improves the conduit’s ability to resist deformation, it also makes installation more challenging in colder environments. PVC pipes that are too rigid may crack or break if they are forced into tight bends or angles during installation. In cases of particularly cold weather, installers may need to heat the conduit or use specialized tools to bend it without causing damage.

4.2 Reduced Impact Resistance

One of the key downsides of PVC at low temperatures is its reduced ability to withstand impacts. As the temperature drops, the material becomes brittle and loses much of its inherent shock-absorbing capacity. This makes PVC pipes more susceptible to cracking, shattering, or breaking when subjected to sudden impacts or mechanical stress.

Increased Brittleness: PVC becomes more brittle as the temperature falls, especially below freezing point (32°F or 0°C). At these low temperatures, the material can no longer absorb the energy from an impact as effectively, leading to cracks or fractures. Even moderate impacts, such as dropping the pipe, can cause it to break or shatter. This brittleness is particularly problematic during installation, where the risk of the conduit breaking increases if it is dropped, struck, or bent too forcefully.

Risks: The risk of cracking or shattering is heightened during transportation, storage, or installation in freezing conditions. In addition, PVC pipes in cold environments are more likely to break under sudden shocks or pressure, such as when a heavy object falls onto the conduit or when a hard tool is used during installation. This not only jeopardizes the physical integrity of the pipe but can also lead to damage of the electrical wiring it is meant to protect.

4.3 Pressure Capacity Enhancements

While high temperatures reduce the pressure resistance of PVC, the material’s pressure capacity improves at low temperatures. This counterintuitive effect occurs because the rigidity of PVC increases as the temperature drops, allowing the conduit to better withstand internal pressure. The material’s ability to resist expansion or deformation under pressure is stronger when it is colder, meaning PVC can endure higher pressures in low-temperature environments.

Mechanism: As the temperature decreases, the polymer chains in PVC become less mobile, which reduces the ability of the pipe to stretch or deform under pressure. This enhanced structural stability means that the pipe is less likely to expand or collapse when subjected to high internal pressure. This is particularly useful in applications where PVC conduit is used in pressurized systems, such as hydraulic, pneumatic, or water systems, and in conditions where the conduit needs to maintain a secure seal or protective barrier.

Example: Consider an underground installation in a freezing climate, where PVC conduit is used to protect electrical wiring. In this scenario, the conduit may need to withstand the internal pressure from the cables or any fluids running through the system. At low temperatures, the conduit’s resistance to pressure is enhanced, making it more suitable for high-pressure applications. This improvement is in contrast to the behavior of PVC at higher temperatures, where the material would be more prone to deformation and reduced pressure capacity.

4.4 Additional Considerations for Low-Temperature Installations

Handling and Installation: When working with PVC in low temperatures, it’s essential to handle the pipes carefully to avoid cracking or damaging the material. Installers may need to preheat the pipes before installation, especially in freezing temperatures, to maintain flexibility and avoid sudden impacts that could cause fractures. In some cases, using heating blankets or room-temperature storage for PVC pipes prior to installation can prevent brittle failure.

Expansion and Contraction: While PVC becomes stiffer and more rigid in cold temperatures, it still undergoes expansion and contraction with temperature fluctuations. These changes, although less noticeable in cold weather, still need to be accounted for during installation. Installers should leave sufficient space for the conduit to expand during warmer months to prevent unnecessary stress on joints and fittings.

Long-Term Performance: Over time, exposure to cold temperatures can affect the longevity of PVC pipes. While the enhanced pressure capacity is an advantage in the short term, prolonged exposure to extreme cold may eventually cause the material to degrade or become brittle, especially if subjected to repeated freezing and thawing cycles. To mitigate this, PVC pipes used in outdoor applications may need to be regularly inspected for cracks, leaks, or other signs of material fatigue.

By understanding how PVC behaves in low-temperature environments, installers can take the necessary steps to ensure the conduit remains safe and functional over time, providing reliable protection for electrical systems even in the harshest climates.

5. Practical Implications for Installation and Design

5.1 Adapting to Temperature Changes

When designing and installing PVC conduit systems, it’s crucial to consider the temperature fluctuations that the system will encounter during its lifecycle. Since PVC is a thermoplastic material, it will expand when heated and contract when cooled, which can lead to misalignments, joint failures, or system stress if not properly accounted for.

5.1.1 Designing Systems to Accommodate Expansion and Contraction: One of the most important considerations when designing PVC conduit systems in environments subject to temperature changes is ensuring the system can accommodate thermal expansion and contraction. This requires planning for both the material’s natural movement and the potential stress placed on the joints and fittings as the pipe length changes.

Expansion Joints and Compensators: In long conduit runs, especially those exposed to outdoor conditions, installing expansion joints or compensators is critical. These fittings are specifically designed to absorb the linear movement caused by temperature changes. They allow the system to expand and contract without causing undue stress on the joints or the conduit itself, ensuring the integrity of the installation over time.

Allowing for Slack and Movement: Where possible, leave some slack or flexibility in the system to account for expansion. This is especially important in areas with extreme temperature fluctuations. For instance, if the PVC conduit passes through walls or rigid mounting points, ensure that it is not installed too tightly. Allowing a small amount of slack can prevent the pipe from becoming pinched or stressed as it expands and contracts.

5.2 Selecting the Right PVC Grade

The selection of the right PVC grade for your installation plays a significant role in ensuring the system performs optimally in extreme temperatures. Not all PVC materials are suited for both hot and cold environments, and using the wrong grade can lead to premature wear, cracking, or loss of functionality.

5.2.1 Heat-Resistant Formulations for Hot Climates: For installations in hot climates where temperatures consistently exceed typical operating conditions, selecting a heat-resistant PVC formulation is essential. These special grades of PVC are designed with additives that enhance their ability to withstand high temperatures without losing structural integrity. Heat-resistant PVC can maintain its flexibility and pressure capacity at elevated temperatures, making it an ideal choice for outdoor and industrial applications in hot regions.

Heat Stabilizers: Some formulations contain heat stabilizers that slow the degradation process caused by prolonged exposure to high temperatures. This helps to maintain the material’s strength, rigidity, and resistance to UV degradation, making it suitable for long-term use in sunny or arid environments.

5.2.2 Reinforced or Flexible PVC for Cold Environments: In colder climates, PVC can become brittle and more susceptible to cracking under pressure or impact. To mitigate these issues, using reinforced or flexible PVC grades is recommended. Reinforced PVC incorporates additional materials such as fiberglass or metal mesh to provide added strength, while flexible PVC offers greater resistance to brittleness and enhanced impact resistance at low temperatures.

Flexible PVC: Flexible PVC can be an excellent choice for installations in areas with frequent temperature swings or in locations where impact resistance is essential. It retains more elasticity even at lower temperatures, preventing cracking and ensuring that the system can adapt to the demands of cold weather.

Cold-Weather Formulations: Some manufacturers offer special PVC formulations designed specifically for low temperatures, often with added plasticizers to maintain flexibility and reduce brittleness. These formulations help ensure that the material can endure the stress of freezing temperatures without compromising performance.

5.3 Installation Best Practices

Proper installation practices are crucial to the long-term durability and safety of PVC conduit systems, especially in environments with extreme temperatures. Below are some key tips for handling PVC pipes in both hot and cold conditions:

5.3.1 Handling PVC in Cold Weather: PVC becomes stiffer and more brittle in cold temperatures, which makes it more prone to cracking during installation. To prevent damage during handling and installation:

Pre-Warming Pipes: In very cold weather, it’s advisable to pre-warm PVC pipes before installation. This can be done by allowing the pipes to gradually warm up to room temperature or using a heating blanket to gently raise the temperature of the pipes. This will make the pipes more flexible and easier to handle without the risk of cracking.

Use Proper Tools: Always use the correct tools when handling PVC in cold temperatures, as using blunt or forceful tools can cause the material to fracture. Cutting, joining, or bending PVC should be done slowly and carefully to prevent any sudden impacts that could cause the material to shatter.

Wear Protective Gear: When handling PVC in cold temperatures, be sure to wear gloves and protective eyewear. Cold pipes can become slippery, and improper handling could lead to injury or material damage.

5.3.2 Handling PVC in Hot Weather: High temperatures can make PVC more flexible, which might make it more prone to kinking or warping if it is not handled properly during installation.

Avoid Prolonged Exposure to Heat: During installation, avoid leaving PVC pipes exposed to direct sunlight or high temperatures for prolonged periods before they are set in place. Heat can cause them to soften and warp. If working in hot environments, try to handle the pipes early in the morning or later in the day when the temperature is lower, or store the pipes in a shaded area until they are needed.

Proper Fitting and Alignment: Due to the increased flexibility at high temperatures, ensure that PVC pipes are correctly aligned and secured during installation to prevent them from becoming misshapen or sagging. Use supports and hangers that are designed to handle the thermal expansion of the pipes and prevent any shifting during use.

5.3.3 Installation of Fittings and Joints: When installing PVC fittings and joints, ensure that they are properly aligned and that the solvent cement is applied evenly. Fittings should be securely fastened, and the solvent cement should be allowed to cure fully before subjecting the system to temperature extremes. In high temperatures, it’s particularly important to allow extra curing time to ensure that the cement has fully set and the bond is strong.

6. Comparative Analysis: PVC vs. Other Materials

6.1 PVC vs. Metal Conduits

When comparing PVC (Polyvinyl Chloride) to metal conduits, several key differences emerge that highlight the advantages and limitations of each material in electrical installations. These differences impact factors such as thermal expansion, durability, and resistance to environmental conditions.

Thermal Expansion: One of the most significant differences between PVC and metal conduits is their reaction to temperature changes. PVC has a higher coefficient of thermal expansion, which means it expands and contracts more with temperature fluctuations compared to metals like steel or aluminum. While PVC can tolerate these changes with the proper expansion fittings, metal conduits tend to be more stable under varying temperatures. This stability can make metal conduits more reliable in systems where consistent alignment is crucial, as they are less prone to warping or shifting.

Durability: Both materials offer durability, but in different ways. PVC is resistant to corrosion, which makes it a superior choice for environments prone to rust or chemical exposure. In contrast, metal conduits, such as steel, are more susceptible to corrosion over time, especially in humid or wet environments, unless they are treated or coated with protective layers like galvanization. However, metal conduits generally offer better resistance to impact and mechanical stress compared to PVC, which is more prone to cracking under extreme conditions.

Resistance to Environmental Factors: PVC conduits are generally more resistant to environmental factors like UV radiation, particularly when UV-resistant additives are used. This makes them a better choice for outdoor or exposed applications where sunlight is a factor. Metal conduits, on the other hand, can degrade under prolonged UV exposure, requiring additional coatings to prevent damage. In terms of temperature resistance, metal conduits typically handle extreme temperatures better than PVC, which can soften at high temperatures and become brittle in the cold.

Cost: PVC is generally more affordable than metal conduits, which can make it a more economical option for large-scale installations. While metal conduits may offer greater long-term durability in certain applications, the initial cost of PVC is a significant advantage, especially for projects on a budget or for installations where cost-effectiveness is a key factor.

Weight: PVC is lighter than metal conduits, making it easier to handle and install, particularly in long runs or complex installations. This lighter weight also reduces shipping costs and the overall load on the structure. Metal conduits, while offering better structural strength, can be heavy and require more labor during installation.

6.2 PVC vs. HDPE (High-Density Polyethylene)

PVC and HDPE (High-Density Polyethylene) are both widely used materials for electrical conduits, but they differ in flexibility, temperature resilience, and applications.

Flexibility: HDPE is more flexible than PVC, making it a better option for installations that require bending or conforming to complex layouts. PVC, while it can be bent in some cases, is more rigid than HDPE and may require fittings or tools for bends. HDPE’s flexibility allows it to be installed more easily in situations where conduit needs to be routed around obstacles or in tight spaces without using additional bending tools.

Temperature Resilience: In terms of temperature resilience, HDPE outperforms PVC, particularly in low-temperature environments. HDPE maintains its flexibility and impact resistance in colder temperatures, whereas PVC becomes more brittle and susceptible to cracking or breaking. In high-temperature environments, both materials can experience reductions in pressure capacity, but HDPE generally retains more of its structural integrity under heat compared to PVC, making it a better choice for extreme conditions.

Durability and Resistance to Chemicals: Both materials offer excellent resistance to chemicals, but HDPE has superior resistance to cracking under stress and is more durable in environments where exposure to harsh chemicals, oils, or gases is a concern. PVC is still quite resistant to chemicals but may degrade faster when exposed to some solvents or acids.

Cost: While both materials are generally affordable, PVC is usually the more cost-effective option, particularly in residential or light-duty applications. HDPE, being more durable and flexible, tends to be more expensive and is often used in industrial or commercial applications where additional strength and resistance are needed.

Applications: HDPE is often preferred in applications involving underground installation, such as in trenching or areas with a high risk of mechanical impact. PVC, on the other hand, is more commonly used in above-ground installations where stability and affordability are key factors.

6.3 PVC vs. UPVC (Unplasticized Polyvinyl Chloride)

UPVC is a variation of PVC that has not been mixed with plasticizers, giving it a rigid, solid form that is more suitable for certain applications than regular PVC. The key differences between PVC and UPVC focus on their rigidity, temperature resilience, and application areas.

Rigidity and Strength: UPVC is much more rigid and stronger than standard PVC due to the absence of plasticizers, which gives it higher tensile strength. This makes UPVC ideal for applications that require additional structural integrity, such as water or gas piping systems, and electrical conduits in areas with potential mechanical stress. PVC, while still strong, offers more flexibility but may not have the same load-bearing capacity as UPVC.

Temperature Resistance: UPVC has better temperature resistance than standard PVC. While both materials can tolerate moderate temperatures, UPVC is more stable in high-temperature environments and is less prone to warping or softening. Standard PVC tends to soften at elevated temperatures, making UPVC a more reliable option for installations exposed to extreme heat.

Applications: UPVC is commonly used in industries that require a higher level of rigidity and pressure tolerance, such as plumbing and drainage systems. However, it is also used in electrical installations, especially for rigid conduit systems where extra strength and rigidity are needed. PVC, being more flexible and easier to handle, is often used in above-ground electrical conduit installations where bending and ease of handling are more important than structural strength.

Cost: UPVC tends to be slightly more expensive than standard PVC, mainly due to its enhanced properties and the absence of plasticizers. However, it still remains relatively affordable compared to materials like metal or HDPE, making it a viable option for applications that require a higher strength-to-weight ratio at a moderate cost.

In conclusion, selecting the right PVC conduit for your project is crucial for ensuring the long-term performance and safety of your electrical systems. It’s important to consider the specific needs of the project, including factors such as the type of installation, the level of protection required, and the environmental conditions. By understanding the temperature range and weather conditions of the location, you can choose the most suitable conduit material that will perform optimally under those conditions.

Whether you’re dealing with extreme heat, freezing temperatures, or fluctuating climates, ensuring your conduit is built to withstand these environmental factors will help guarantee the reliability and durability of your electrical system. Make informed decisions by considering both the technical requirements and environmental conditions to achieve the best results for your project.

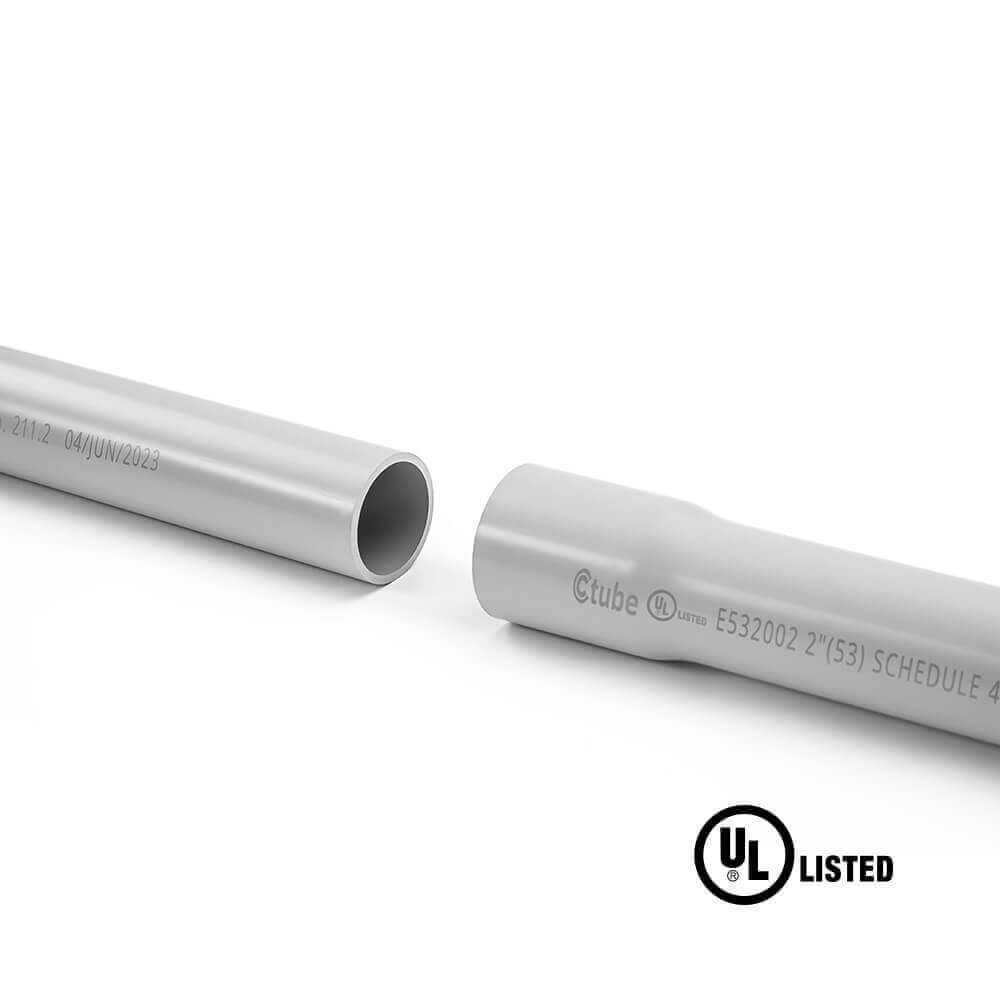

Ctube is a leading manufacturer of high-quality PVC conduits and fittings, offering innovative solutions designed to meet the diverse needs of electrical installations across various industries. With a focus on durability, performance, and safety, Ctube products are engineered to withstand a wide range of environmental conditions, ensuring reliable protection for electrical wiring. Our PVC conduits are crafted to meet international standards and are available in various sizes and specifications. We have electrical conduit comply with UL listed, CSA certified and AS/NZS 2053 standard, also offer solar series and low smoke halogen free series conduit.

Our products are built to endure extreme temperature variations, with a wide temperature range that ensures functionality in both high-heat and cold environments. Common withstand -15℃ to +105℃, low smoke halogen free conduit withstand -45℃ to +150℃. The versatility of Ctube’s PVC conduits makes them ideal for applications in diverse climates, maintaining their integrity even in fluctuating conditions. With features like UV protection, resistance to impact, and enhanced flexibility, Ctube conduits provide long-lasting protection and efficiency in various installation settings, from residential to industrial. Whether in scorching heat or freezing temperatures, Ctube’s products ensure your electrical systems stay safe and reliable.

FAQs

1. Are there specific grades of PVC designed for high-temperature applications?

Yes, there are specialized grades of PVC formulated with additives that enhance their performance under high-temperature conditions. These materials may offer improved heat resistance and durability compared to standard PVC. Such as UPVC and low smoke halogen free material.

2. How does cold weather impact the tensile strength of PVC conduits and pipes?

Cold weather generally increases the tensile strength of PVC pipes, making them better able to withstand internal pressure and external loads. However, it can also decrease their impact resistance, making them more susceptible to cracking under sudden stress.

3. How does temperature affect the curing time of PVC cement?

Temperature significantly influences the curing time of PVC cement. Lower temperatures can slow down the curing process, leading to weaker joints, while higher temperatures can accelerate curing but may also lead to rapid evaporation of solvents, affecting joint quality.

The ideal temperature range for applying PVC cement is typically between 40°F and 90°F. Some products are formulated for colder conditions, allowing application in temperatures as low as -15°F.

How Temperature Affects PVC Electrical Conduit Pipes Read More »