How to Choose the Right Electrical Conduit for Your Project by Application

1. Introduction to Choosing the Right Electrical Conduit Project

Choosing the right electrical conduit for your project is crucial for ensuring the safety, efficiency, and longevity of your electrical installations. Electrical conduits act as protective pathways for wiring, shielding them from physical damage, moisture, and environmental factors. The appropriate conduit selection can prevent hazards such as electrical fires, short circuits, and wire degradation, contributing to a safe and reliable electrical system. Additionally, the right conduit facilitates easier maintenance and future upgrades, reducing downtime and labor costs, which is particularly important in complex installations where accessibility and flexibility are paramount.

When selecting the right electrical conduit, several critical factors must be considered. The type of application—whether indoor or outdoor—significantly impacts the choice.. In contrast, outdoor installations demand conduits that can withstand various environmental factors due to their durability and resistance to harsh conditions. Special environments, such as industrial facilities or healthcare settings, may have unique requirements like chemical resistance or the ability to maintain a sterile environment, necessitating the use of specialty conduits designed to meet these needs.

Environmental conditions, building codes, and installation requirements are also vital considerations. Compliance with local building codes and standards is essential for ensuring safety and reliability, with different regions having specific regulations governing conduit types and installation practices. Additionally, the ease of installation, flexibility, and structural support requirements of the conduit should be evaluated to ensure that the chosen conduit can be adequately supported and secured. By carefully considering these factors, you can make an informed decision, ensuring compliance with safety standards and enhancing the overall efficiency and durability of your electrical installations.

2. Understanding Different Types of Electrical Conduit

Choosing the right electrical conduit for your project is essential for ensuring the safety, efficiency, and longevity of your electrical systems. Electrical conduits are categorized into two main types: metallic and nonmetallic. Each category has unique properties suitable for various applications, depending on environmental conditions, installation requirements, and specific project needs.

2.1 Detailed Overview of Metallic and Nonmetallic Conduits

Metallic conduits are renowned for their strength and durability, making them ideal for applications where mechanical protection is paramount. They are typically used in commercial and industrial settings where physical damage is a concern. Here are two common types of metallic conduits

2.1.1. Galvanized Rigid Conduit (GRC)

– Description: Galvanized Rigid Conduit (GRC) is a thick-walled conduit made from galvanized steel, providing superior physical protection for electrical wiring. The galvanization process involves coating the steel with a layer of zinc, which enhances its corrosion resistance.

– Applications: GRC is commonly used in outdoor and industrial environments where high durability is required. It is suitable for exposed installations in high-traffic areas, underground installations, and in areas prone to mechanical damage. It is also widely used in commercial buildings, parking structures, and utility services.

– Benefits: GRC offers excellent mechanical protection and corrosion resistance, making it suitable for harsh environments. It can withstand extreme weather conditions and is highly durable, ensuring long-term reliability. Additionally, GRC provides excellent grounding and can be used as an equipment grounding conductor, enhancing the overall safety of the electrical system.

– Drawbacks: GRC is heavier and more challenging to work with compared to other conduits. Installation requires threading and special tools, increasing labor time and costs. Its rigidity can make it difficult to maneuver in tight spaces, and it is more expensive than some other conduit types. The weight and bulk of GRC also necessitate robust support structures during installation.

2.1.2. PVC-Coated Steel Conduit

– Description: PVC-coated steel conduit features a steel core with an outer PVC coating, combining the strength of steel with the corrosion resistance of PVC. The PVC coating provides an additional layer of protection against moisture, chemicals, and other corrosive elements.

– Applications: This conduit is ideal for corrosive environments such as chemical plants, marine applications, and areas with high moisture levels. It is also used in food processing facilities and other settings where hygiene and corrosion resistance are critical. Additionally, PVC-coated steel conduit is suitable for areas prone to saltwater exposure, such as coastal regions and offshore installations.

– Benefits: The PVC coating provides excellent corrosion resistance, extending the lifespan of the conduit. It also offers additional insulation for the electrical wiring, reducing the risk of electrical faults. PVC-coated steel conduit can withstand harsh environmental conditions and is suitable for both indoor and outdoor applications. It also maintains the mechanical strength of steel while providing the added benefits of a non-metallic outer layer.

– Drawbacks: PVC-coated steel conduit is more expensive than standard steel conduit and can be challenging to install due to its rigidity. The PVC coating can be damaged during installation if not handled carefully, potentially compromising its protective properties. Additionally, the conduit requires specialized fittings and accessories compatible with the PVC coating, which can further increase costs.

2.2 Non metallic Conduits

Nonmetallic conduits are lightweight and corrosion-resistant, making them suitable for a wide range of applications, particularly in residential and commercial settings. Here are two popular types of nonmetallic conduits

2.2.1 PVC Conduit

– Description: Polyvinyl chloride (PVC) conduits come in different schedules, with SCH 40 and SCH 80 being the most common. SCH 40 is lighter and used for most applications, while SCH 80 has thicker walls for added protection and can handle higher mechanical stress.

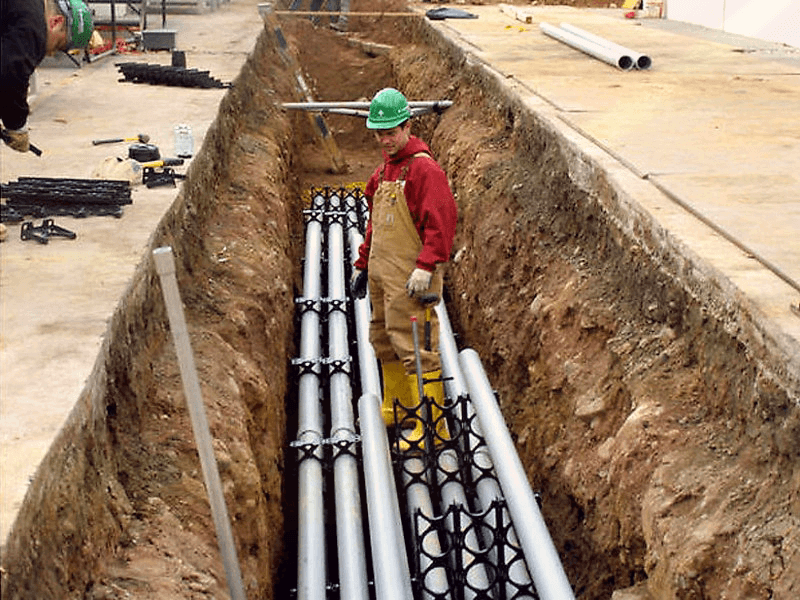

– Applications: PVC conduits are used in underground installations, direct burial, and wet or corrosive environments. They are also suitable for residential wiring, commercial buildings, and outdoor applications. PVC conduits are often used in utility installations, including water treatment plants, irrigation systems, and telecommunications. They are also a popular choice for low-voltage applications such as alarm systems and data cabling.

– Benefits: PVC conduits are lightweight, easy to install, and resistant to corrosion and moisture. They offer good insulation for electrical wiring, reducing the risk of electrical faults. PVC conduits are cost-effective and can be easily cut and joined using solvent cement, making installation quick and straightforward. They also have a smooth interior, reducing friction for easier wire pulling. PVC conduits are non-conductive, eliminating the risk of electrical shock and making them safer for certain applications.

– Drawbacks: PVC conduits can become brittle in extremely cold temperatures and may require additional protection in high-impact areas. They are not suitable for high-temperature environments as they can deform or melt. Additionally, PVC conduits are not as strong as metallic conduits and may not provide adequate mechanical protection in some industrial applications. While they are corrosion-resistant, they may degrade over time when exposed to UV light without proper protection.

2.2.2 Fiberglass Conduit (RTRC)

– Description: Reinforced thermosetting resin conduit (RTRC), commonly known as fiberglass conduit, is made from fiberglass-reinforced epoxy resins. This type of conduit is known for its high strength-to-weight ratio and excellent corrosion resistance.

– Applications: RTRC is ideal for environments with extreme temperatures, high moisture, and corrosive substances. It is commonly used in industrial settings, outdoor installations, chemical plants, and areas where electromagnetic interference (EMI) must be minimized. Fiberglass conduits are also suitable for use in tunnels, bridges, and other infrastructure projects where durability and long-term performance are critical.

– Benefits: Fiberglass conduits are lightweight, offering ease of handling and installation. They provide excellent corrosion resistance and can withstand high temperatures, making them suitable for extreme environments. RTRC conduits are non-conductive, providing additional safety for electrical installations by reducing the risk of electrical faults and minimizing EMI. They are also flame-resistant, enhancing safety in fire-prone areas. The material’s high strength-to-weight ratio makes it suitable for long runs and challenging installations without requiring extensive support structures.

– Drawbacks: RTRC can be more expensive than other nonmetallic conduits and may require special fittings and adhesives for installation. The installation process can be more complex, requiring skilled labor. While RTRC is durable, it may not be as readily available as other conduit types, potentially leading to longer lead times for procurement. Additionally, the initial cost of RTRC and its accessories may be higher compared to more common conduit types.

3. Application-Specific Considerations for Choosing Electrical Conduit

Electrical conduits are essential components in electrical systems, providing protection and organization for wiring in various environments. Choosing the right conduit involves considering specific factors tailored to the application, whether indoors or outdoors.

3.1 Indoor Applications

3.1.1 Importance of Aesthetics and Space Constraints

– Aesthetics: Conduits visible in living or working spaces should complement the interior design. Options like paintable conduits or those designed to blend with walls and ceilings can enhance aesthetics.

– Space Constraints: Limited space may require conduits that are compact and can be installed in tight areas without obstructing other utilities or storage spaces.

3.1.2 Considerations for Ease of Installation and Flexibility

– Ease of Installation: Conduits should be easy to handle and install to minimize disruption during construction or renovation. Lightweight materials or prefabricated conduit systems can expedite installation processes.

– Flexibility: Flexible conduits are ideal for navigating around corners, obstructions, and irregular building layouts. They reduce the need for additional fittings and can accommodate changes in wiring configurations.

3.2 Outdoor Applications

3.2.1 Need for UV Resistance and Weatherproofing

– UV Resistance: Conduits exposed to sunlight must withstand UV degradation to maintain their structural integrity over time.

– Weatherproofing: Outdoor conduits need robust weatherproofing to prevent water ingress and protect against environmental elements. Sealed fittings, gaskets, and corrosion-resistant materials ensure long-term reliability.

3.2.2 Ensuring Moisture Resistance to Prevent Corrosion and Electrical Hazards

– Moisture Protection: Moisture infiltration can lead to corrosion of electrical components and pose safety risks. Conduits with effective seals and moisture-resistant properties prevent water penetration and safeguard internal wiring.

3.2.3 Considerations for Physical Protection and Maintenance

– Physical Protection: Outdoor conduits should provide adequate protection against physical damage from impact, abrasion, and environmental hazards. Choosing conduits with durable construction and optional protective covers enhances longevity.

– Maintenance: Minimizing maintenance requirements simplifies ongoing upkeep. Accessible inspection points and easy repair options, such as removable covers or modular designs, facilitate troubleshooting and maintenance tasks.

4. Project-Specific Challenges and Solutions in Selecting Electrical Conduit

Electrical conduit selection is pivotal in ensuring the reliability and efficiency of electrical installations. This essay explores the nuanced challenges and strategic solutions involved in choosing electrical conduits, focusing on weight considerations, cutting and bonding procedures, joining systems, and hanger systems.

4.1 Weight Considerations

– In construction projects, particularly in residential or commercial buildings, the weight of conduits plays a crucial role in installation efficiency and worker safety.

– Lightweight materials such as PVC (Polyvinyl Chloride) or fiberglass conduits are preferred for their ease of handling and maneuverability. They reduce the physical strain on installers and allow for quicker installations.

– Applications where lightweight conduits excel include overhead installations in ceilings, where ease of lifting and positioning is essential, and retrofit projects where space constraints necessitate lightweight materials.

4.2 Joining Systems

– The choice of joining systems depends on the conduit material, installation environment, and required flexibility.

– For rigid conduits like GRC or PVC-coated steel, joining methods include threaded connections, compression fittings, or push-fit connectors. Threaded connections provide a secure, reliable seal suitable for heavy-duty applications, while compression fittings offer quick installation and easy disassembly.

– Flexible metal conduits often use fittings that allow bending without compromising the conduit’s structural integrity. Liquid-tight connectors with sealing gaskets are common in applications requiring protection against liquids, oils, or contaminants.

4.3 Cutting and Bonding Procedures

4.3.1 Simplified Installation Processes for Specific Conduit Types

– Different conduit materials require specific tools and techniques for cutting and bonding to ensure a secure and reliable installation.

– PVC Conduits: PVC conduits can be easily cut using a hacksaw, PVC cutter, or specialized conduit cutters. The smooth surface of PVC facilitates solvent welding, where a solvent cement is applied to the surfaces of the conduit and fitting, creating a strong, permanent bond.

– Metal Conduits: Metal conduits such as GRC (Galvanized Rigid Conduit) or EMT (Electrical Metallic Tubing) require tools like pipe cutters or hacksaws for cutting. Joining methods include threading, compression fittings, or couplings depending on the conduit type and application.

4.3.2 Bonding Procedures

– Bonding ensures that conduits maintain structural integrity and prevent leaks or separations over time.

– For PVC conduits, solvent welding involves applying a solvent cement to both the conduit ends and the fitting, allowing them to chemically bond. This method creates a watertight seal suitable for both indoor and outdoor applications.

– Fiberglass conduits may use epoxy adhesives or resin bonding to achieve a strong, durable connection. These bonding techniques are critical in environments where corrosion resistance and long-term reliability are paramount.

4.4 Hanger Systems

4.4.1 Appropriate Hanger Systems for Supporting Different Conduit Types

– Proper support through hanger systems is crucial to prevent sagging, maintain alignment, and ensure compliance with electrical codes.

– Conduit Types and Weight Considerations Selecting the right hanger system involves considering conduit material, weight, installation location (indoor or outdoor), and environmental factors such as seismic activity.

4.4.2 Examples of Hanger Systems

– Adjustable beam clamps are versatile and can accommodate various conduit sizes and weights. They provide secure attachment to structural beams or surfaces.

– Conduit straps offer straightforward installation and support for lightweight conduits in vertical or horizontal runs.

– Trapeze hangers are ideal for supporting multiple conduits in long runs, providing stability and reducing stress on installations subjected to vibrations or movement.

The selection of electrical conduits involves addressing project-specific challenges related to weight, installation procedures, joining methods, and hanger systems. By understanding these challenges and implementing appropriate solutions tailored to the application, project stakeholders can optimize conduit installations for efficiency, safety, and long-term performance in diverse electrical environments.

5. Additional Resources for Choosing the Right Electrical Conduit

When planning your electrical conduit system, utilizing the right tools and resources can significantly streamline the process and ensure optimal results. Here are comprehensive resources to assist you in selecting and designing your conduit system.

5.1 Links to Online Calculators for Conduit Sizing and Bending

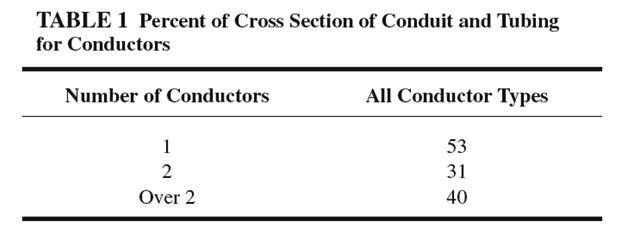

Accurately sizing and bending conduits are critical to ensuring they meet your project’s electrical requirements and spatial constraints. Online calculators provide convenient tools to calculate conduit sizes based on the number and type of cables, as well as bending requirements to fit around corners and obstacles. These calculators help optimize material usage and ensure compliance with safety and performance standards.

Conduit Sizing Calculators: Utilize online tools provided by electrical supply websites or conduit manufacturers. These calculators allow you to input parameters such as cable diameter, fill ratio, conduit type (e.g., PVC, metal), and environmental factors (temperature, moisture) to determine the appropriate conduit size for your specific application.

Conduit Bending Calculators: These tools assist in calculating precise angles and dimensions required to bend conduits accurately. By inputting parameters like conduit type, diameter, and bend radius, you can ensure that conduits fit smoothly into your installation without compromising cable integrity or conduit durability.

5.2 Access to BIM/Revit Models for Planning and Design

Building Information Modeling (BIM) and Revit models offer detailed 3D representations of conduit systems within larger construction projects. Integrating BIM models allows for accurate planning, visualization, and coordination of conduit routes with other building systems. These models enhance collaboration among project stakeholders and facilitate efficient design iterations, ensuring that conduit systems integrate seamlessly into overall building plans.

BIM Libraries: Many conduit manufacturers provide BIM libraries featuring their products. These libraries include detailed models of conduit components that architects, engineers, and contractors can integrate into their digital building models. This integration ensures accurate placement and routing of conduits, enhancing overall project efficiency and reducing potential clashes during construction.

Revit Families: Specific Revit families for conduit components enable detailed placement and visualization within architectural and engineering design software. These families include parametric data and specifications, allowing for precise coordination and integration of conduits with other building systems, such as electrical, HVAC, and plumbing.

5.3 Contact Information for Expert Advice and Further Assistance

Navigating the complexities of conduit selection and installation can benefit from expert guidance. Manufacturers and industry experts offer invaluable advice on product specifications, installation best practices, and compliance with regulatory standards. Contacting these experts ensures that you make informed decisions and address any project-specific challenges effectively.

Manufacturer Support: Conduit manufacturers provide technical support services, including product recommendations, customization options, and assistance with interpreting specifications and standards. Their expertise helps in selecting the right conduit materials and configurations that meet project requirements and ensure long-term performance.

Industry Associations and Consultants: Electrical industry associations and consulting firms specialize in conduit systems and offer consultancy services. They provide expert guidance on conduit selection, installation techniques, and regulatory compliance. Engaging with these professionals ensures adherence to industry best practices and standards, optimizing the efficiency and reliability of your conduit installations.

6. Conclusion: Choosing the Right Electrical Conduit for Enhanced Safety and Efficiency

6.1 Importance of Selecting the Right Electrical Conduit

Choosing the right electrical conduit for your project is a critical step in ensuring the safety, efficiency, and longevity of your electrical installations. This article has explored the importance of selecting appropriate conduits by application, considering factors such as environmental conditions, building codes, and specific project requirements. By understanding the unique demands of indoor and outdoor installations, and recognizing the need for specialized conduits in environments like industrial facilities and healthcare settings, project stakeholders can make informed decisions that enhance the overall performance and reliability of their electrical systems.

The detailed examination of metallic and nonmetallic conduits highlights the distinct advantages and potential drawbacks of each type. Understanding these characteristics allows for the selection of conduits that best match the specific needs of each project, ensuring compliance with safety standards and facilitating ease of installation and maintenance.

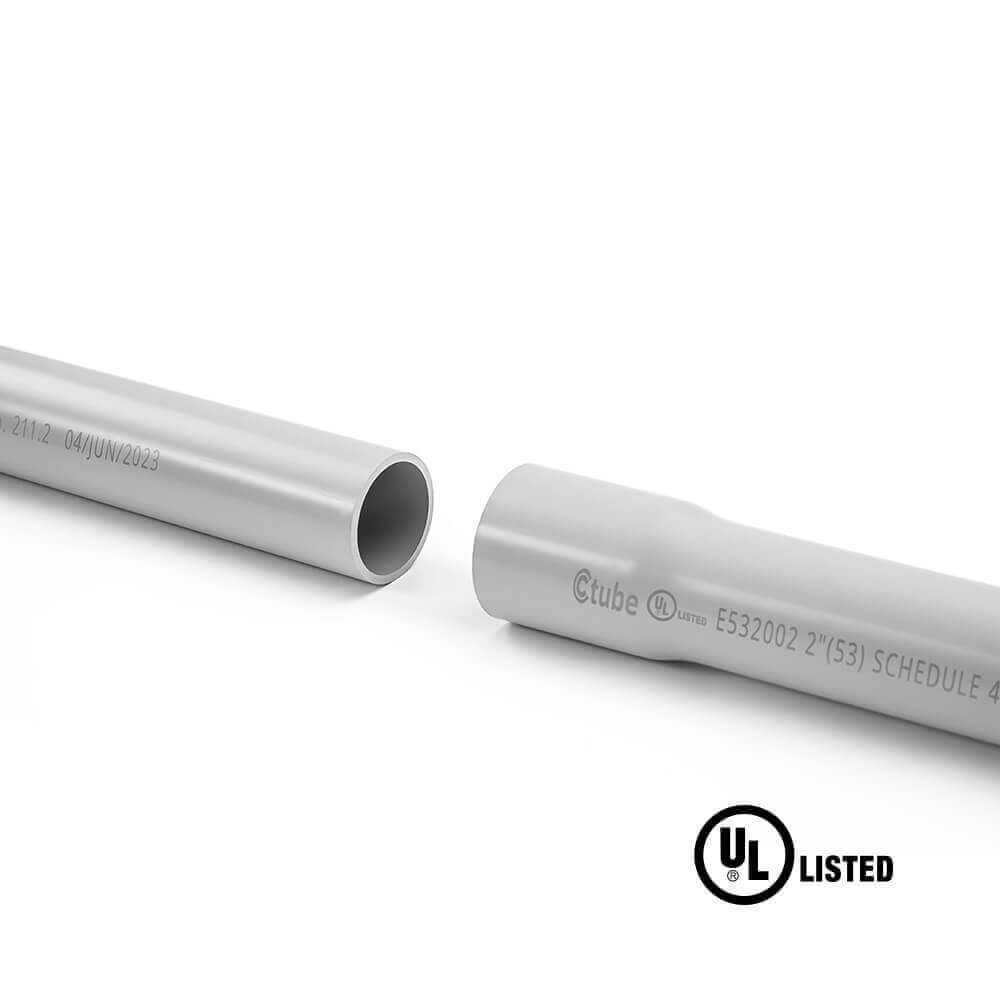

6.2 Ctube: Delivering High-Quality PVC Conduits for Diverse Applications

At Ctube, with over a decade of experience in manufacturing PVC conduits and fittings, we are dedicated to producing high-quality products that offer numerous benefits. PVC conduit is renowned for its lightweight nature and cost-effectiveness, as well as its waterproof and anti-corrosion properties. However, there are common concerns regarding the use of PVC conduit in outdoor environments, particularly the potential reduction in service life due to the material’s susceptibility to brittleness.

To address these concerns, Ctube’s photovoltaic solar series conduits and fittings are designed with enhanced UV resistance components, significantly extending their lifespan in outdoor applications. This makes them exceptionally suited for environments with prolonged sun exposure. Additionally, we manufacture a low-smoke halogen-free series, which minimizes smoke production in the event of combustion or fire and prevents the release of toxic gases, thereby enhancing the safety of both human life and property.

Our commitment to innovation and quality ensures that Ctube’s products meet the high standards of durability and safety, providing reliable solutions for a wide range of applications. Whether for indoor or outdoor use, our PVC conduits and fittings are engineered to deliver superior performance and longevity, making them a trusted choice for professionals in the industry.

How to Choose the Right Electrical Conduit for Your Project by Application Read More »