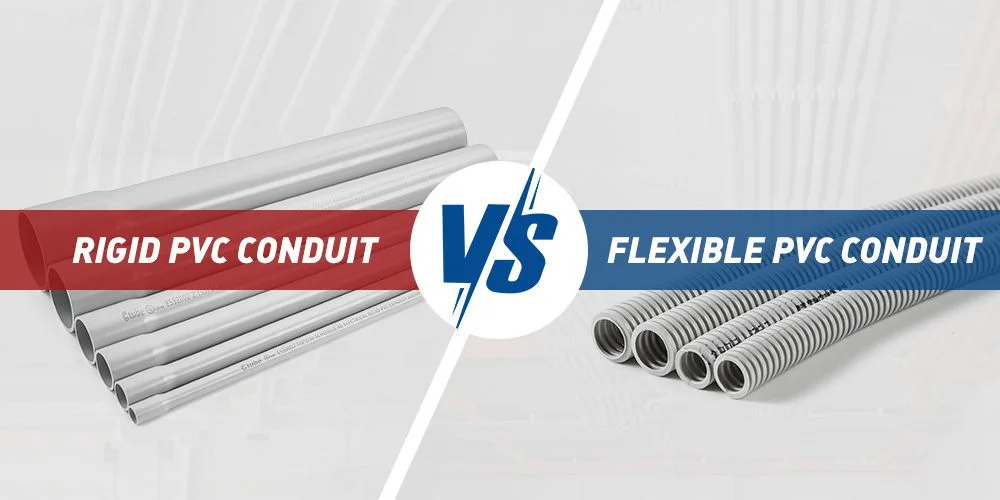

Rigid PVC Conduit Vs. Flexible PVC Conduit

When planning electrical wiring installations, the choice of conduit is an important factor that impacts protection, longevity and cost. Two popular conduit options are rigid PVC conduit and flexible PVC conduit. While both are made from PVC, they differ in key aspects related to strength, installation flexibility and suitability for different environments. In this post, we will provide an in-depth comparison of rigid versus flexible PVC conduit to help you determine the best type for your specific project needs.

Know about Rigid PVC Conduit

What is Rigid PVC conduit?

Rigid PVC conduit, also known simply as PVC conduit, is a durable tubing used for routing electrical wiring in installations. It is made from polyvinyl chloride (PVC), a rigid thermoplastic commonly used in piping and construction due to its advantageous properties.

PVC offers strength and rigidity without being overly brittle. Rigid PVC conduit retains its shape well and will not bend, kink, or compress easily like other materials. This maintains a consistent interior diameter to protect encased wiring.

Its rigidity makes it well-suited to harsh installation environments where physical protection is paramount. PVC conduit withstands weathering, moisture, chemical exposure, impacts and pressures without degrading or losing its protective form.

PVC is non-conductive and corrosion-resistant as well. This adds an essential layer of safety for wiring installations in industrial, commercial and outdoor settings. Neither water nor soil can lead to oxidation or short circuits over time.

Lightweight yet durable, rigid PVC conduit sees wide application everywhere from underground electrical lines to building wiring runs to extension cords for power tools. It meets various industry standards for electrical installation materials and carries approvals for plenum and riser spaces.

Overall, rigid PVC conduit excels at providing robust sheathing for wiring networks. Its stiffness and strength maintain full coverage without weakening in demanding conditions. For applications requiring physical shielding, PVC conduit offers limitless usefulness and longevity.

Know about Flexible PVC Conduit

What is Flexible PVC Conduit?

Flexible PVC conduit shares the base material of rigid PVC conduit but with a key difference – it is formulated to bend and flex rather than maintain a fixed shape. This variant is also commonly called liquid-tight flexible metal conduit.

Like rigid PVC, flexible PVC begins as polyvinyl chloride (PVC). However, plasticizers are added into the compound. Plasticizers act as softening agents that increase the pliability of the PVC without compromising its other properties.

This addition allows the conduit tube to conform to twisting turns and curves yet still offer robust protection. Flexible PVC can coil and unfold smoothly along complex wiring routes.

Where rigid PVC is stiff, flexible PVC bends and shapes easily by hand for installation around corners, obstructions and tight spaces. No specialized heat-shaping or fittings are needed at bend points like with rigid conduit runs.

While flexible, this type of PVC conduit does not kink or collapse in on itself even after repeated bending. It retains an open round channel and remains durable for long-term use in a dynamic setting.

Applications suited to flexible PVC conduit include industrial machinery, mobile equipment, vibrating machinery and locations where periodic cable access is needed. Its flexibility streamlines installations that rigid conduit could not navigate.

The Differeces Between Rigid PVC Conduit and Flexible PVC Conduit

Rigid PVC Conduit:

1. Maintains a fixed shape and will not bend or deform easily

2. Provides robust physical protection for wiring

3. Requires precise cutting and joining pieces during installation

4. Best for applications that need maximum durability

5. More suitable for outdoor installations that face weathering

6. Initial material costs tend to be lower

Flexible PVC Conduit:

1. Contains plasticizers that allow it to bend and flex into curves

2. Easier to install around corners and obstructions

3. Tolerates vibration and minor impacts better

4. Installation is simpler for complex routing paths

5.Allows for cable runs that may experience dynamic movement

6. Material costs higher than rigid PVC

7.But installation labor reduced with easy bending

8. Total costs may be lower for complicated runs

Factors to Consider When Choosing Rigid or Flexible PVC Conduit

Protection Needs

Is the wiring going to be exposed to hazards like impacts, moisture or corrosion? Rigid conduit might be better for maximum shielding in demanding outdoor or industrial settings.

Installation Complexity

How many bends and turns will the routing take? Flexible conduit would make my life much easier if snaking around multiple obstacles. Rigid could mean more fittings and joints to worry about.

Cost Impact

Flexible material is pricier but may save me time in the long run. I’d have to estimate meters needed and calculate fitting costs to see the real cost difference for each job. Small complex jobs might favour flexible conduit.

Code Requirements

Electrical code is crucial – it might specify the type of conduit needed based on environmental or fire protection factors. I’d check with the inspector to stay compliant.

Client Factors

Consider the budget but also my client’s preferrences if they have any. Rigid may provide more long-term reassurance for demanding applications.

Future Access

Will serviceability be needed? Flexible conduit could allow repulling cables without dismantling sections like with rigid bends.

Overall I would look at the job holistically – deciding based on a range of protection, installation and economic variables specific to that application. Consulting with suppliers on the best options also helps make an informed choice as the licensed installer. Safety and code compliance are top priorities in my decision.

Rigid PVC Conduit Vs. Flexible PVC Conduit Read More »