PVC conduits are one of the most popular types of electrical conduits used in construction projects. They are made of polyvinyl chloride, a type of plastic that is durable, lightweight, and easy to install. PVC conduits come in different thicknesses, or schedules, with SCH 40 and SCH 80 being the most common. In this article, we’ll explore the differences between SCH 40 PVC conduits and SCH 80 PVC conduits and help you choose the right one for your next project.

Table of Contents

ToggleWhat are SCH 40 PVC Conduits?

SCH 40 PVC conduits are a type of PVC pipe that have a thicker wall than other types of PVC conduits, making them more durable and resistant to damage. The “SCH” in SCH 40 stands for “schedule,” which refers to the pipe’s wall thickness. SCH 40 PVC conduits are the most commonly used PVC conduits in electrical installations due to their affordability, durability, and ease of installation.

One of the main advantages of SCH 40 PVC conduits is their ease of installation. They are lightweight and easy to cut, which makes them easy to work with. Additionally, they are resistant to corrosion and chemicals, which makes them ideal for use in harsh environments. Lastly, SCH 40 PVC conduits have a smooth interior surface, which reduces friction and makes it easier to pull wires through them.

What are SCH 80 PVC Conduits?

SCH 80 PVC conduits are a type of PVC pipe that have a thicker wall than SCH 40 PVC conduits. This thicker wall makes them more durable and resistant to damage, making them ideal for use in more demanding electrical installations. SCH 80 PVC conduits are more expensive than SCH 40 PVC conduits, which makes them less popular among some contractors and electricians.

One of the main benefits of SCH 80 PVC conduits is their higher pressure rating. They can withstand higher pressures than SCH 40 PVC conduits, making them ideal for use in applications where high pressure is a concern. Additionally, SCH 80 PVC conduits are more resistant to heat and fire than SCH 40 PVC conduits, making them ideal for use in areas where fire safety is a concern.

The Differences between Schedule 40 PVC Conduit and Schedule 80 PVC Conduit

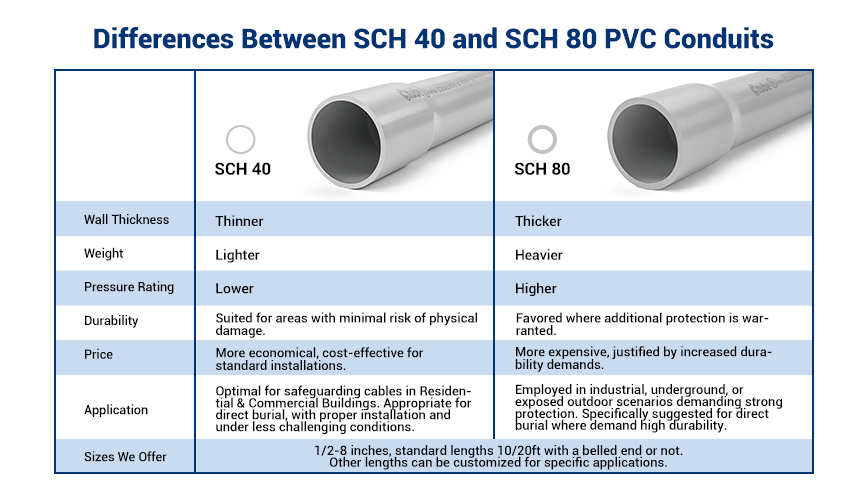

Wall thickness

The wall thickness is the key difference between conduit schedules.

Schedule 40 conduit has thinner walls than schedule 80 conduit of the same size. The outside diameter is the same for both schedules, so they can be used interchangeably. However, schedule 80’s increased thickness is on the inside, resulting in a smaller inner diameter.

Weight

An identical 1.315″ diameter schedule 80 conduit weighs 0.406 lbs compared to 0.327 lbs for schedule 40 due to the thicker wall material.

Installation

Ease of installation is affected too. Schedule 40’s wider inner diameter makes wire pulling simpler, while schedule 80 can accommodate fewer wires of the same size.

However, schedule 80’s thicker walls provide greater protection against damage in heavy traffic or hazardous conditions.

Color

Color is generally the same – both are typically gray. Specific uses may see different colors like orange for fiber.

Price

Schedule 40 conduits are weaker due to using less material. Schedule 80’s thicker walls impart greater rigidity, durability and strain resistance suitable for demanding applications.

Not surprisingly, schedule 80 conduits cost more to produce because of the extra material in their walls and any colorants added. Their higher rated performance comes at a higher price

Applications

Schedule 40 PVC electrical conduit is commonly used for installations in ceilings, floors, walls, underground in concrete enclosures, and for exposure to direct sunlight.

Schedule 80 conduit has a wider scope of application, as it can be used anywhere schedule 40 conduit is suitable.

The National Electrical Code (NEC) requires schedule 80 conduit for above-ground installations where physical damage is likely to occur. The thicker walls of schedule 80 provide enhanced safety in these hazardous locations by acting as an additional layer of protection against impacts or abrasion that could damage thinner-walled conduits over time.

SCH 40 PVC Conduits vs. SCH 80 PVC Conduits: Which One Should You Choose?

When it comes to choosing between SCH 40 PVC conduits and SCH 80 PVC conduits, there are several factors to consider:

Durability: SCH 80 PVC conduits are more durable than SCH 40 PVC conduits and can withstand more wear and tear. However, SCH 40 PVC conduits are still quite durable and are ideal for use in most electrical installations.

Price: SCH 40 PVC conduits are more affordable than SCH 80 PVC conduits, making them a popular choice among many contractors and electricians.

Pressure rating: SCH 80 PVC conduits have a higher pressure rating than SCH 40 PVC conduits, making them ideal for use in applications where high pressure is a concern.

Fire safety: SCH 80 PVC conduits are more resistant to heat and fire than SCH 40 PVC conduits, making them ideal for use in areas where fire safety is a concern.

Ease of installation: SCH 40 PVC conduits are easier to install than SCH 80 PVC conduits due to their lighter weight and easier cutting.

Ultimately, the choice between SCH 40 PVC conduits and SCH 80 PVC conduits will depend on your specific needs and requirements. If you are looking for an affordable and durable PVC conduit that is easy to install, SCH 40 PVC conduits may be the right choice for you. If you need a PVC conduit that can withstand higher pressures and is more resistant to heat and fire, SCH 80 PVC conduits may be the better choice. Regardless of which type of PVC conduit you choose, be sure to work with a reputable supplier to ensure that you are getting a high-quality product that meets all industry standards.

Conclusion

For most indoor wiring projects in the home, schedule 40 PVC conduit will suit your needs effectively. But if installing conduit in an outdoor environment or industrial setting prone to impacts, the extra wall thickness of schedule 80 conduit offers superior protection of your electrical system.

Product links:

[1] Schedule 40 PVC Conduit – https://www.pvcconduitmanufacturer.com/schedule-40-pvc-conduit/

[2] Schedule 80 PVC Conduit – https://www.pvcconduitmanufacturer.com/schedule-80-pvc-conduit-electrical-pipe/