1. Introduction: Understanding Electrical Conduits

When you’re planning an electrical wiring project—whether it’s for your home, a commercial building, or an industrial site—choosing the right type of electrical conduit is essential.

Electrical conduits are protective tubes that safely carry and organize wires. They protect your wiring from moisture, chemicals, physical damage, and even fire.

But with so many types available, it can be confusing to know which one to choose. That’s why this article breaks everything down in a simple and clear way.

Whether you’re a contractor, electrician, engineer, or just a homeowner curious about the basics, this guide will help you understand the different kinds of conduits and where each one is best used.

2. Major Categories of Electrical Conduit

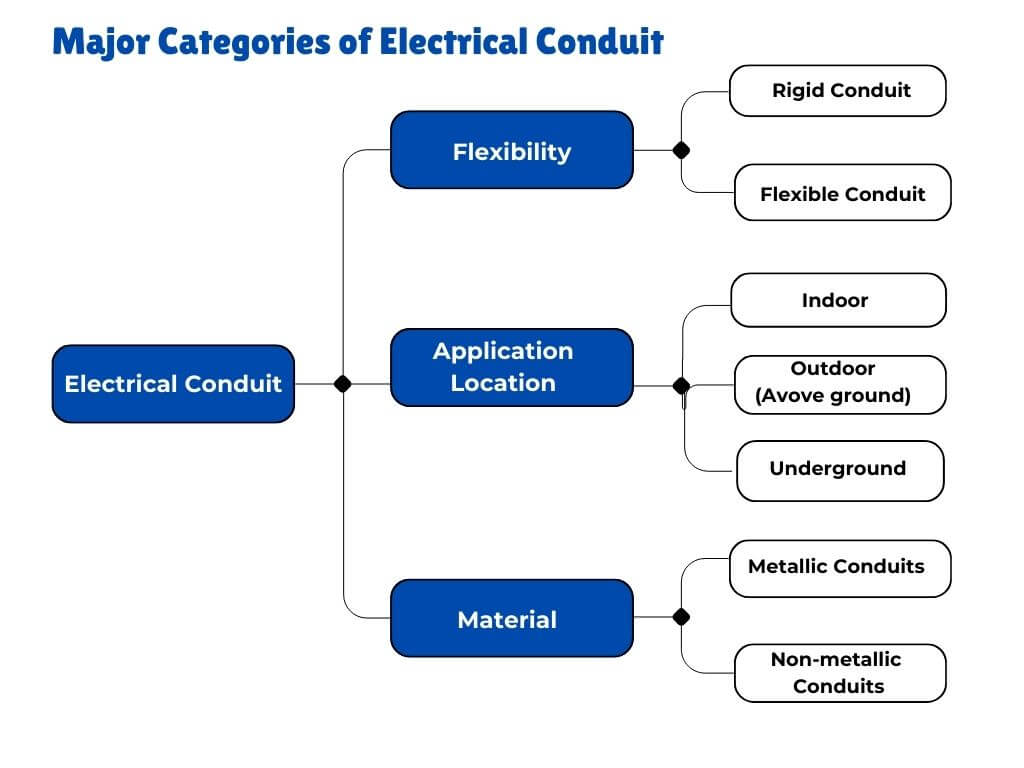

Electrical conduits can be grouped in different ways depending on what you’re focusing on.

Some people classify them by how flexible they are—rigid or flexible. Others look at where they’re used—indoor, outdoor, or underground.

However, one of the most important ways to categorize conduits is by the material they are made of.

Based on material, electrical conduits are mainly divided into two major types:

👉 Metallic conduits and Non-metallic conduits.

This article will focus on these two categories, explaining what makes them different, what types fall under each group, and how to choose the right one for your specific project needs.

3. Types of Metal Electrical Conduits

Metallic conduits are made from solid, durable materials that offer strong protection for electrical wiring—especially in environments where wires may be exposed to mechanical stress or harsh conditions.

3.1 Materials of Rigid Metal Conduit and Flexible Metal Conduit

While several metals can be used to manufacture conduits, the most commonly used materials include:

Steel: The most widely used material for metallic conduits. It’s strong and impact-resistant, making it ideal for both indoor and outdoor installations. Steel conduits are often galvanized to prevent rust.

Stainless Steel: Chosen for its excellent corrosion resistance, especially in environments that are damp, chemical-heavy, or coastal. It’s more expensive than standard steel but provides long-term durability.

Aluminum: Lightweight and naturally corrosion-resistant, aluminum conduits are easier to handle and are often used where weight matters—such as on ceilings or in commercial buildings. However, they are softer than steel and less impact-resistant.

Have a brief understanding of the material; let’s take a closer look at the most common types of metallic conduits.

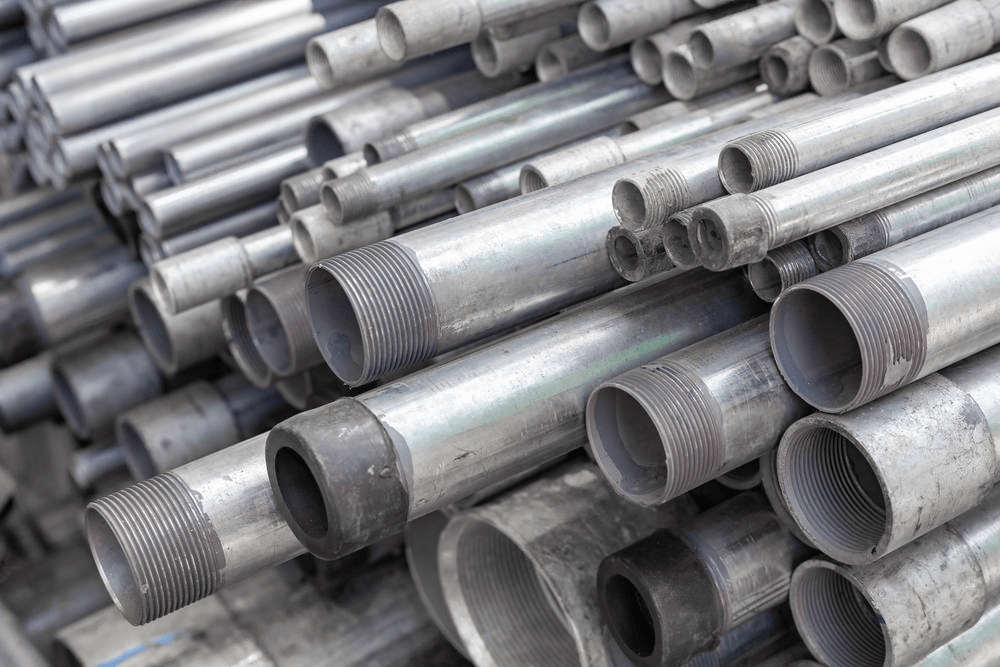

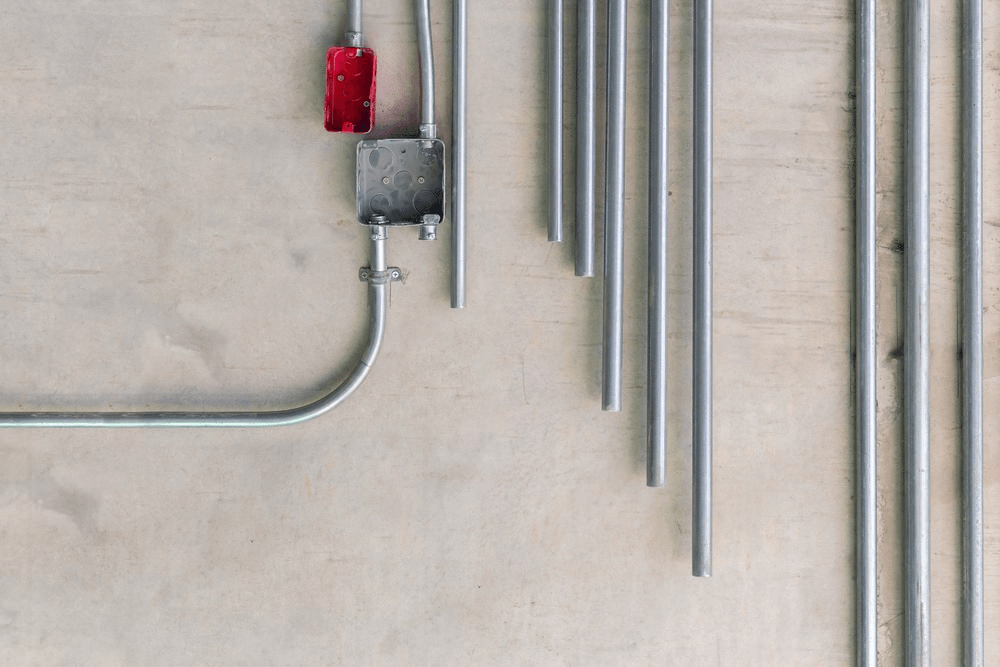

3.2 Rigid Metal Conduit (RMC), RGS & GRC

Rigid Metal Conduit, or RMC, is a strong and thick-walled type of metal conduit used to protect electrical wires. It’s usually made from galvanized steel, but it can also be made from aluminum, stainless steel, or even brass in some cases.

You might also hear the terms RGS (Rigid Galvanized Steel) or GRC (Galvanized Rigid Conduit). These are different names for the same type of conduit — they all refer to rigid conduits made of galvanized steel. The name used may vary by region or industry, but the product is basically the same.

RMC conduits have thick-walled and threaded at both ends for secure, watertight connections.

3.3 Intermediate Metal Conduit (IMC)

Intermediate Metal Conduit (IMC) is a steel conduit that provides solid protection for electrical wires and cables. IMC is designed to meet the National Electrical Code (NEC), NFPA 70 standards and is available in trade sizes from 1/2 inch to 4 inches (metric designators 16–103). It is used to route and protect wiring in a wide range of applications, from homes and offices to industrial and commercial buildings.

IMC also has threaded ends, which allows it to be joined with standard threaded fittings—just like RMC.

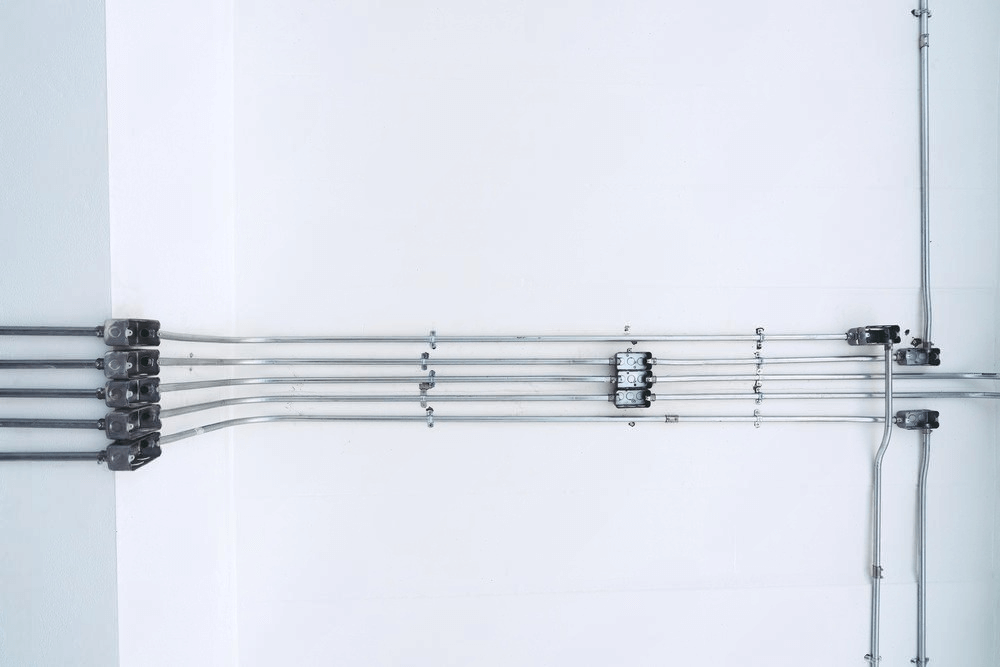

3.4 Electrical Metallic Tubing (EMT)

EMT conduit is a lightweight, thin-walled metal electrical pipe used for protecting and routing electrical wires. EMT conduit is designed for use as a metal raceway for electrical wiring in accordance with the National Electrical Code (NEC), NFPA 70.

EMT includes aluminum and stainless steel tubing, available in trade sizes 1/2 inch to 4 inches (16 mm – 103 mm).

Coated EMT—featuring a zinc or corrosion-resistant exterior and organic or zinc interior—is covered by UL 797, the standard for steel EMT.

Electrical Metallic Tubing (EMT) typically does not have threaded ends. Instead, it requires special connectors, such as compression fittings or set-screw connectors, to securely join the sections of conduit.

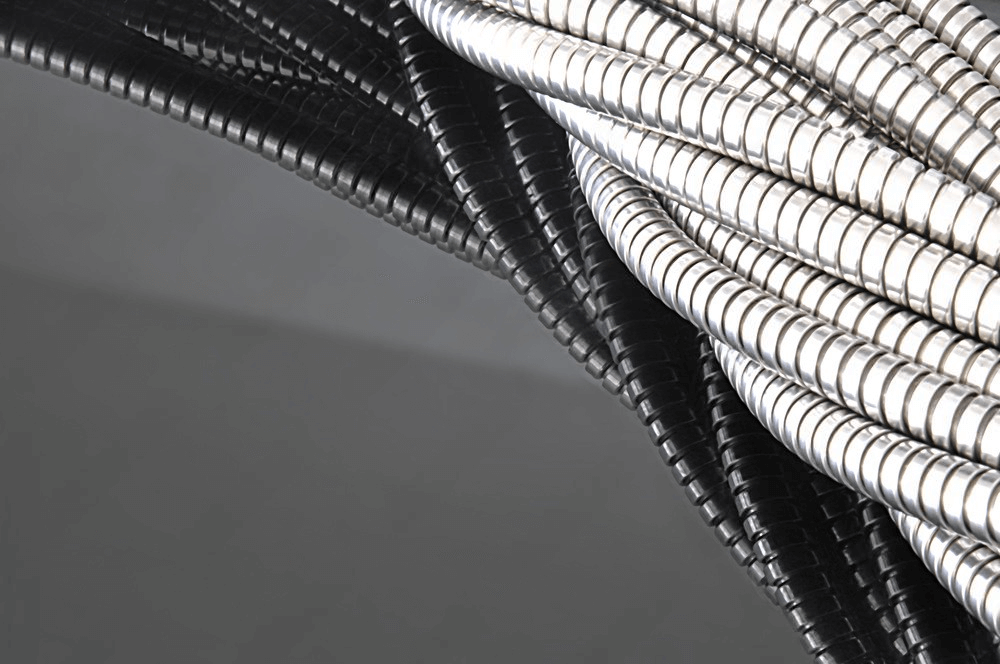

3.5 Flexible Metal Conduit (FMC)

Flexible Metal Conduit (FMC) is a versatile conduit used in electrical installations, designed to offer flexibility while providing robust protection for electrical wiring.

FMC is made from two primary materials: steel and aluminum. Both materials offer excellent strength and flexibility, with slightly different characteristics suited for various applications.

FMC has a spiral or helical design, where the metal strip is wound in a spiral pattern, allowing the conduit to be flexible.

The metal’s smooth, shiny surface (due to the zinc coating) gives it a sleek look. The spiral construction is not only functional but also gives the conduit a slightly ridged appearance, enhancing its grip and resistance to bending under pressure.

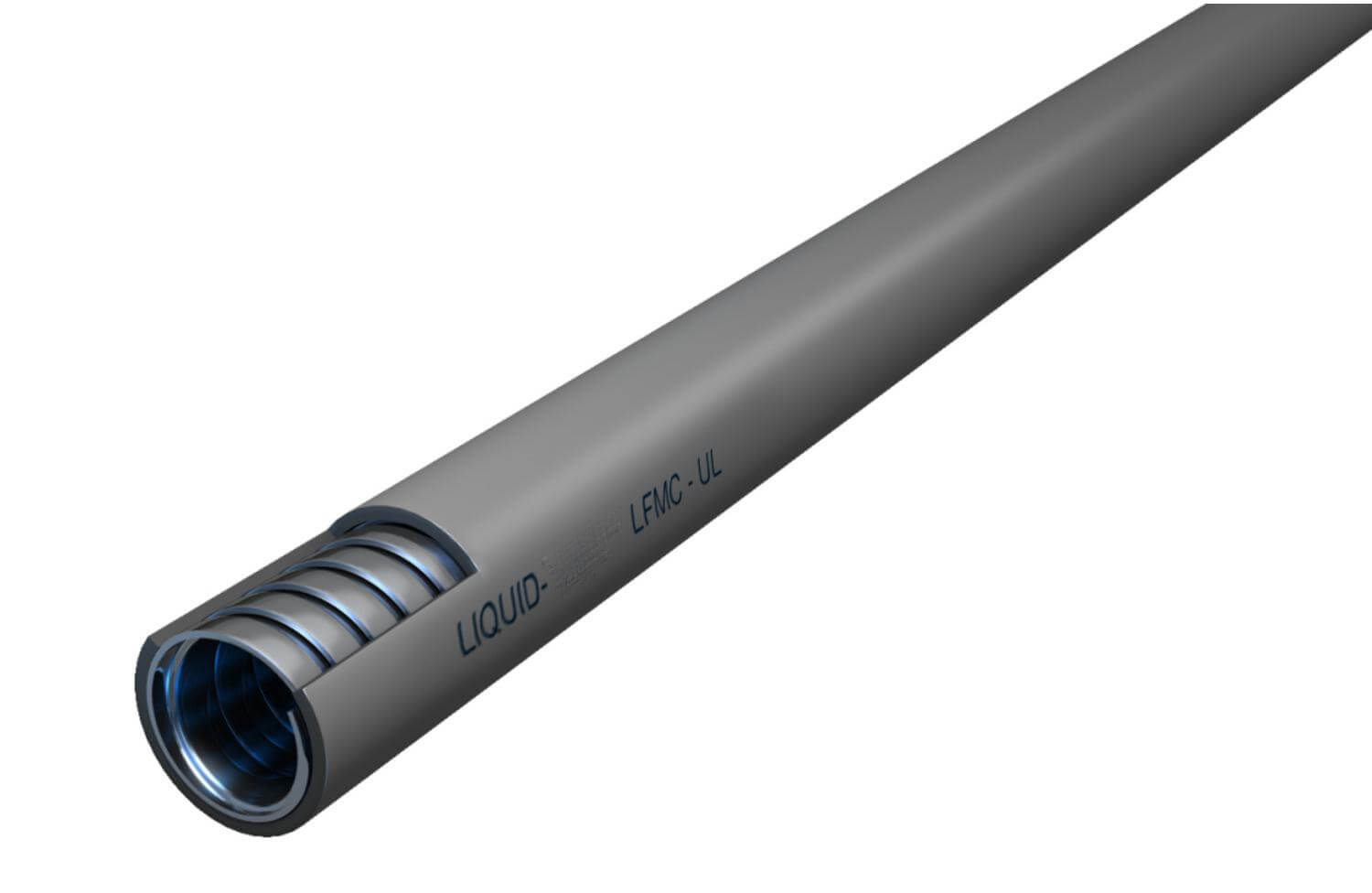

3.6 Liquidtight Flexible Metal Conduit (LFMC)

LFMC conduit is similar in structure to standard flexible metal conduit (FMC), but with a key difference: it has a smooth, non-metallic outer protective jacket that helps seal out water, oils, and other liquids. And this outer layer is typically made from materials like PVC or polyethylene.

LFMC tends to be more expensive than standard FMC due to the additional protective coating.

While LFMC is great for liquid protection, it doesn’t provide the same level of mechanical protection as galvanized rigid conduit.

4. Types of Non Metallic Electrical Conduits

Non-metallic conduits are an essential part of electrical installations, offering flexibility, durability, and corrosion resistance.

These conduits are ideal for environments where metallic conduits might corrode or pose a safety risk.

In this chapter, we will explore the various types of non-metallic conduits commonly used in electrical systems, highlighting their key features, benefits, and applications.

4.1 PVC Electrical Conduit: Rigid Electrical Conduit & Flexible Conduit

Polyvinyl Chloride conduit is one of the most widely used types of non-metallic conduits due to its versatility, cost-effectiveness, and ease of installation.

Made from plastic, it provides excellent protection for electrical wiring, especially in environments where moisture, chemicals, and UV exposure are concerns.

Same as metal conduit, plastic conduit have rigid electrical conduit and flexible conduit.

Rigid electrical conduit is a strong, hard tube used to protect and carry electrical wires in buildings and outdoor systems. It’s typically sold in straight 10-foot lengths and has a smooth surface on both the outside and the inside. This smoothness helps make it easy to pull wires through without damage.

Most rigid conduits come with one end flared out, also known as a bell end, so you can simply push the next piece in for easy connection.

If the conduit doesn’t have this bell, you’ll need to use the PVC conduit connector such as the straight coupling to connect two pieces together.

In North America, rigid conduits—especially PVC types—are classified more specifically based on wall thickness and where they’re meant to be installed. The most common types you’ll see like Schedule 40 and Schedule 80, Type EB, Type DB and Type A conduit.

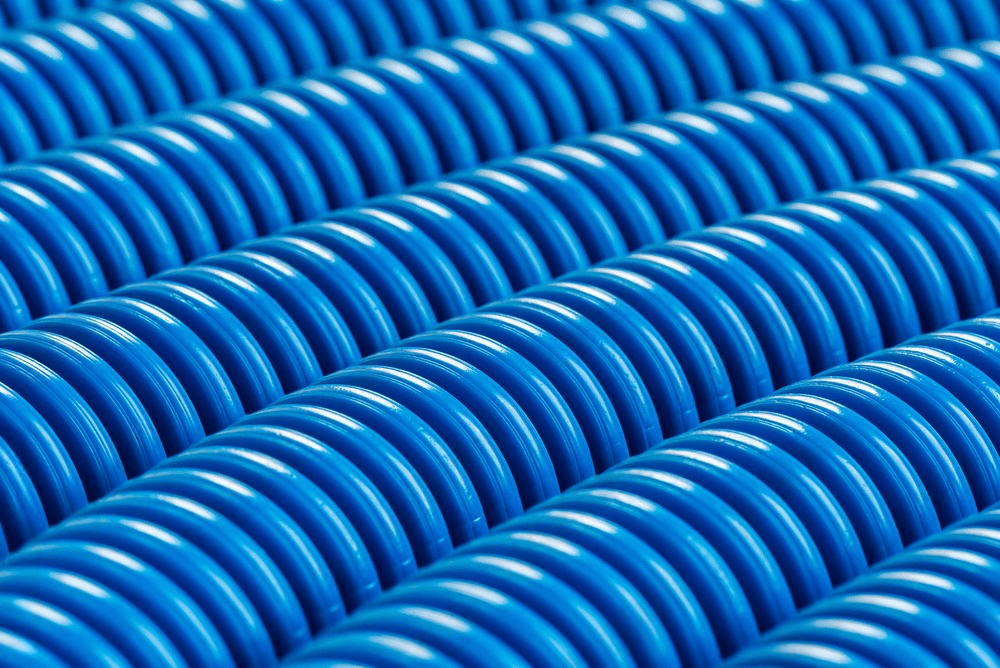

4.2 Electrical Non Metallic Flexible Conduit: ENT & LFNC

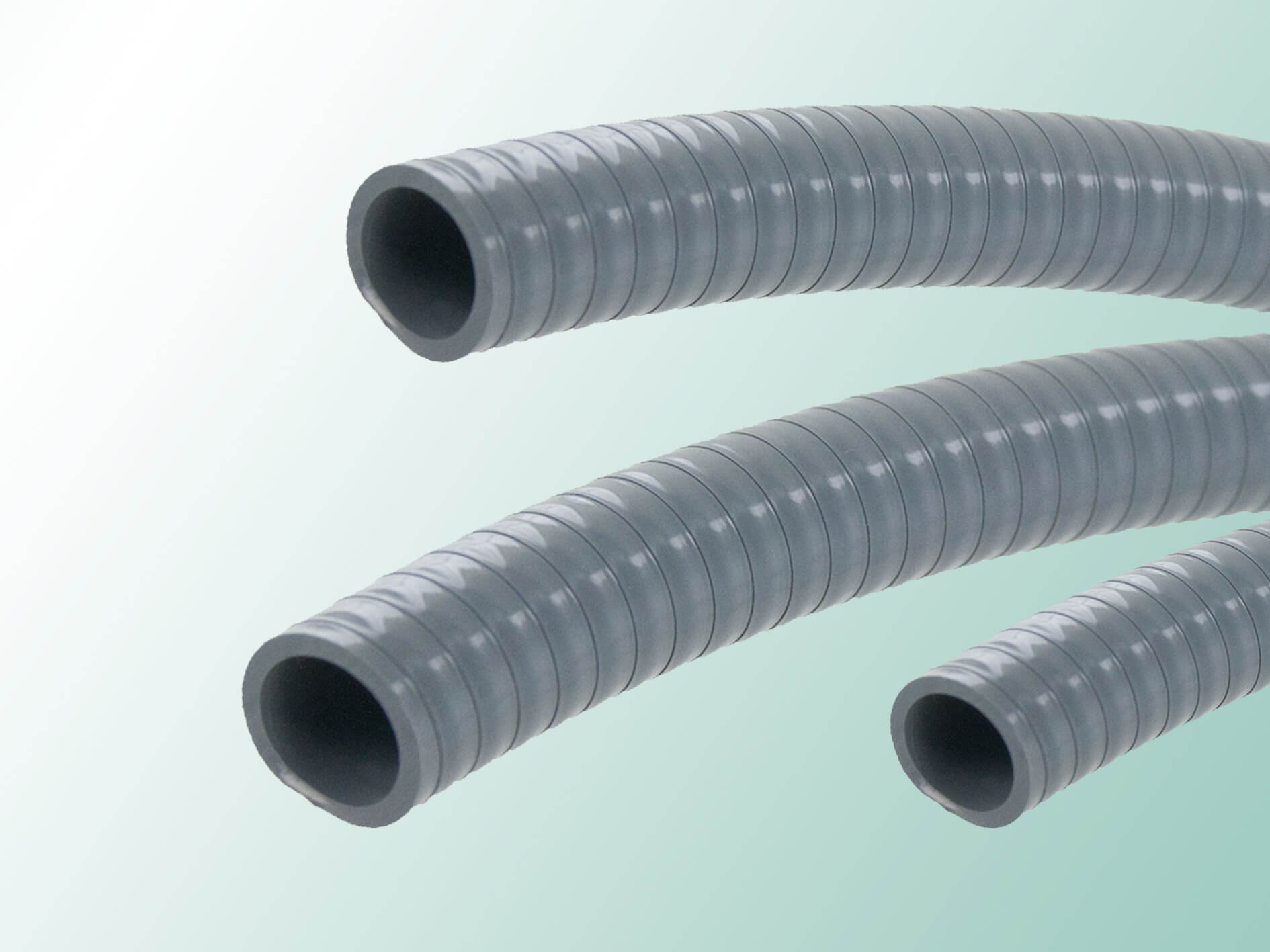

Flexible non metallic conduit is a bendable, flex plastic tubing that’s super easy to recognize. On the outside, it usually has a ribbed or corrugated surface—those little raised ridges give it flexibility and strength at the same time.

This type of conduit is lightweight, easy to install, and doesn’t need any special tools to bend. You can simply curve it by hand to fit around corners or obstacles—no heat, no bending equipment.

Depending on where you are in the world, this conduit might go by different names, but they all refer to the same type of product.

In North America, it’s often called ENT (Electrical Nonmetallic Tubing).

In other places, people might call it flexible conduit or corrugated conduit.

This conduit is especially popular in residential and light commercial projects where quick and flexible wiring is needed, especially in walls, ceilings, or places that are hard to reach.

As we mentioned above LFMC, there is a conduit type call LFNC, or Liquidtight Flexible Nonmetallic Conduit, is a type of plastic conduit designed to keep out moisture while still being flexible and easy to work with.

From the outside, LFNC looks like a plastic hose with a smooth or slightly ribbed surface. It’s flexible, but unlike standard ENT (Electrical Nonmetallic Tubing), it also has a waterproof outer jacket.

Just like LFMC, LFNC can be bent by hand and doesn’t require heat or special tools. But while LFMC is made of metal, LFNC is fully non-metallic, which makes it lightweight and corrosion-resistant.

LFNC is available in different types (like LFNC-A, LFNC-B, and LFNC-C) depending on the thickness of the walls, flexibility, and use case. It’s often used where you need a conduit that’s both flexible and resistant to moisture.

4.3 Reinforced Thermosetting Resin Conduit (RTRC)

Reinforced Thermosetting Resin Conduit, commonly known as RTRC, is a lightweight yet durable conduit made from fiberglass-reinforced plastic (FRP) — a strong combination of fiberglass and resin materials. So people also call this conduit fiberglass conduit or FRP conduit.

It has a smooth, rigid exterior, usually with a matte or dull finish. While it’s not flexible, it’s much lighter than metal conduit and still offers excellent toughness.

The surface is smooth inside and out, which makes pulling wires easier and reduces damage to cables.

Corrosion-resistant and non-conductive, RTRC is perfect for areas with harsh chemicals, moisture, or even underground installations.

4.4 HDPE Electrical Conduit (High-Density Polyethylene)

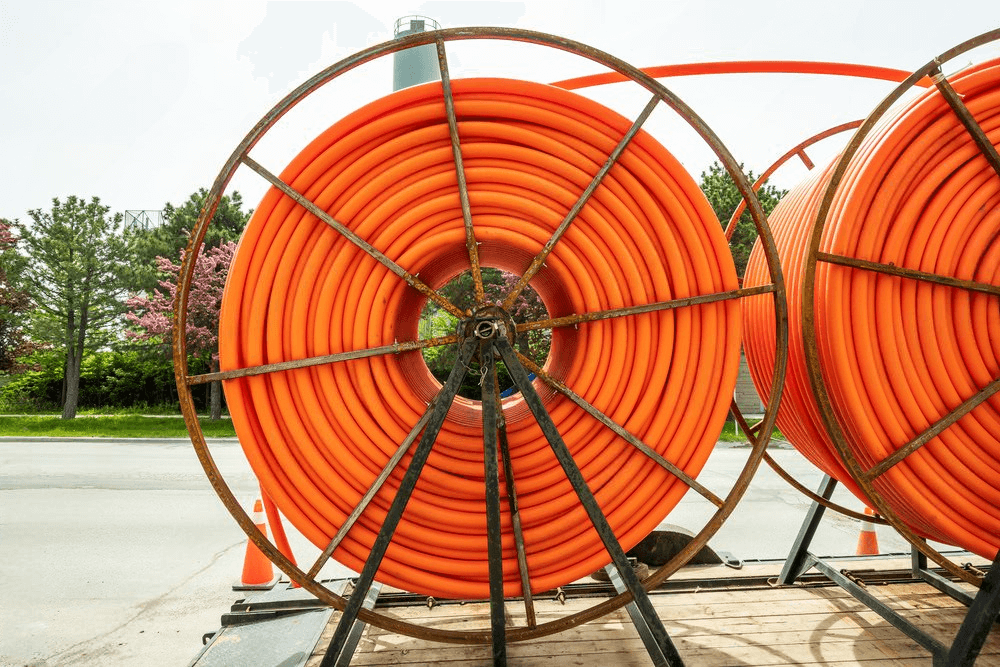

HDPE conduit is a non-metallic, flexible, and durable plastic conduit made from high-density polyethylene. It’s commonly used for underground installations, especially in telecommunications, power utilities, and fiber optic projects.

HDPE electrical pipe typically comes in long, coiled rolls or straight lengths, depending on the installation needs. It’s smooth inside, allowing cables to be pulled through easily.

High-density polyethylene conduit only have flexible type, with corrugated surface or smooth outside types.

The exterior is usually black, but color-coded stripes (like orange, blue, or red) are often added to indicate the type of service (such as power or communications).

5. Choosing Between Metallic and Non-Metallic Conduit

Now that we’ve looked at all the main types of electrical conduit—both metallic and non-metallic—it’s time to think about how to choose the right one for your project.

Each type of conduit has its own strengths. Metallic conduits like RMC, EMT, and FMC offer high strength and good protection in harsh environments. They’re often used in commercial or industrial buildings, or anywhere fire safety and mechanical strength are key.

On the other hand, non-metallic conduits like PVC, HDPE, and ENT are lighter, corrosion-resistant, easier to install, and often more cost-effective. They’re commonly used in underground or residential applications, or when flexibility and ease of handling matter most.

Choosing between metallic and non-metallic conduit depends on factors such as application, budget, regulations, and the specific needs of your project.

If your project plans to use PVC conduit, feel free to contact us. We are Ctube, a electrical conduit supplier that offers a wide range of high-quality solutions, including PVC, uPVC solar conduit, and LSZH conduit.

Our products comply with key international standards such as UL, CSA, AS/NZS 2053, CE, and IEC, ensuring safety, durability, and reliability for your electrical installations. With our expertise and commitment to quality, we are here to support your project needs.

Thanks for your reading, and good luck with your projects.

More you want to know, in the FAQs section.

FAQs

1. RMC VS IMC ?

RMC is the toughest and most durable conduit type. It’s ideal for severe environments, such as outdoor, high-impact, or corrosive areas.

IMC offers a good balance between strength and weight. It’s ideal for most commercial and light industrial applications, where full RMC strength isn’t necessary.

Both are threaded metal conduits, both are galvanized for corrosion resistance, and both can be used in wet and dry locations when installed properly.

2. EMT VS Rigid Metal Conduit?

In many regions, Electrical Metallic Tubing (EMT) is not classified as a type of Rigid Metal Conduit (RMC) due to its lighter weight and thinner walls.

While both are metallic conduits used for wiring protection, they have significant differences in terms of strength, construction, and application suitability.

EMT is lighter, more flexible, and easier to install, making it ideal for residential and light commercial applications.

RMC is thicker, stronger, and provides higher protection against physical damage, making it the go-to choice for industrial and high-risk environments.

3. Metal vs PVC Conduit?

Metal conduit is stronger and more fire-resistant, making it suitable for high-temperature or industrial environments. However, it is heavier, more expensive, and requires special tools for installation. It also conducts electricity, which means extra grounding is often needed.

PVC conduit, on the other hand, is lighter, more affordable, and easier to install. It is highly resistant to corrosion and chemicals, making it ideal for residential, commercial, or underground installations. While not as fire-resistant as metal, some PVC types have flame-retardant properties. PVC is also non-conductive, so it requires additional grounding for electrical safety.