Top 10 Electrical Conduit Manufacturers and Suppliers in Canada

When it comes to electrical installations, having reliable and high-quality conduit systems is crucial. Electrical conduits provide a protective pathway for wiring, ensuring safety and efficiency in various residential, commercial, and industrial applications. In Canada, several manufacturers and suppliers offer top-notch electrical conduit solutions. In this article, we will explore some top listed electrical conduit manufacturers and suppliers in Canada, providing an overview of their products and services.

Electrical conduit systems play a vital role in safeguarding electrical wiring, preventing damage, and ensuring the smooth flow of electricity. With a wide range of options available, it’s important to choose the right conduit manufacturer or supplier to meet your specific needs. In Canada, a number of companies have gained recognition for their exceptional products, reliable performance, and commitment to quality. Whether you’re a contractor, electrician, or homeowner, this information will help you make informed decisions when selecting electrical conduit systems for your projects.

Atkore International

Atkore International is a prominent global manufacturer and supplier of electrical conduit systems, offering a wide range of solutions for various applications. With a strong presence in Canada, Atkore International has established itself as a trusted name in the electrical industry. Let’s delve deeper into what sets Atkore International apart and explore their offerings from several key aspects.

- Extensive Product Range:

Atkore International offers a comprehensive selection of electrical conduit systems, catering to diverse needs and specifications. Their product portfolio includes steel, PVC, and aluminum conduits, ensuring that customers have access to a variety of options to meet their specific project requirements. Whether it’s rigid metal conduit (RMC), intermediate metal conduit (IMC), or flexible conduit, Atkore International delivers high-quality products suitable for both residential and commercial applications.

- Commitment to Quality and Compliance:

Atkore International prioritizes quality and ensures that their products meet industry standards and regulations. Their electrical conduit systems undergo rigorous testing and adhere to stringent quality control processes, guaranteeing durability and reliability. By maintaining compliance with recognized codes and standards, such as the National Electrical Code (NEC) and Canadian Electrical Code (CEC), Atkore International provides peace of mind to customers, knowing they are using safe and reliable conduit systems.

- Innovation and Technological Advancements:

With a focus on continuous improvement, Atkore International remains at the forefront of innovation in the electrical conduit industry. They invest in research and development to introduce advanced technologies and materials that enhance the performance and efficiency of their conduit systems. By staying ahead of emerging trends and incorporating cutting-edge solutions, Atkore International ensures that their customers benefit from the latest advancements in electrical conduit technology.

- Strong Industry Expertise and Support:

Atkore International boasts a team of industry professionals with extensive knowledge and expertise in electrical conduit systems. They provide excellent technical support, assisting customers in choosing the most suitable conduit solutions for their specific projects. Whether it’s consulting on installation methods, guiding through code compliance, or offering customized solutions, Atkore International’s experienced team is dedicated to delivering exceptional service and support.

IPEX

When it comes to electrical conduit systems in Canada, IPEX stands out as a highly regarded manufacturer and supplier. Founded in 1955 and headquartered in Woodbridge, Ontario, IPEX has grown to become a major provider of plastic pipe, fittings, joining systems and specialty tubing.

Production & Distribution:

IPEX manufactures electrical conduit at facilities in Ajax, Ontario and Red Deer, Alberta with a total annual output of 500 million pounds.

They have 12 distribution centers across Canada and the US for rapid delivery to contractors nationwide.

产品组合:

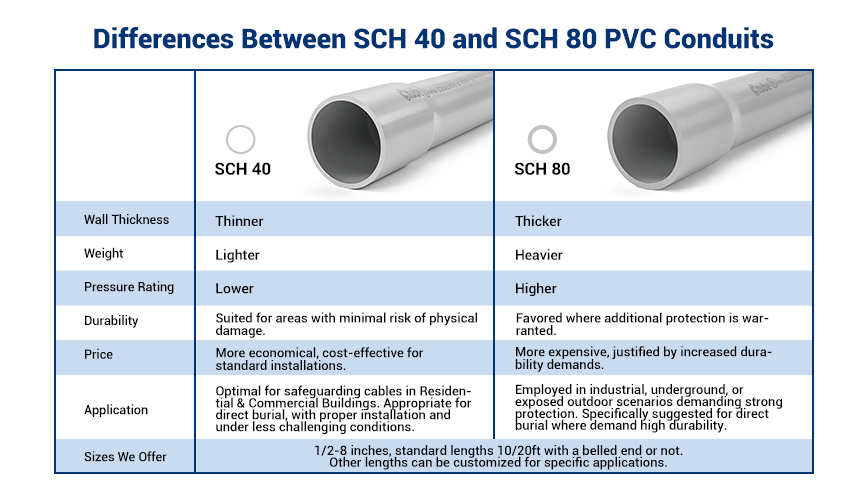

Under the Electrim brand, IPEX offers rigid PVC conduit in standard Schedule 40 & 80 as well as IMC steel conduit.

Their product line also includes ENT tubing and fittings in both flush-mount and set-screw styles.

IPEX provides both wet-location and dry-location conduit solutions.

Quality & Compliance:

All IPEX conduit is third-party certified to Canadian (CSA) and American (UL) standards for electrical installations.

Their proprietary compounds and manufacturing processes ensure optimal rigidity, impact resistance and UV stability.

IPEX undergoes regular audits to maintain ISO 9001 certification for quality management.

Applications:

Popular for both commercial and industrial builds, IPEX conduit is commonly used in offices, warehouses, manufacturing facilities and more.

It is also specified for infrastructure projects like bridges, tunnels and highway lighting installations.With an extensive distribution network spanning Canada and the U.S., IPEX ensures quick access to conduit products for contractors and industrial facilities nationwide. The company prides itself on supply reliability through its strategically located production plants in Ontario and Alberta. IPEX conduit has developed a strong reputation in the Canadian market for quality, dependability and code-compliance over 60 years of industry leadership.

Dura-Line Canada

Dura-Line Canada is a prominent manufacturer and supplier of high-quality conduit and innerduct solutions in Canada. Founded in 1967, Dura-Line manufactures and distributes conduit systems across North America from its HQ in Calgary, AB. With a strong commitment to innovation, durability, and customer satisfaction, Dura-Line Canada has established itself as a trusted name in the industry.

Extensive Product Portfolio:

Dura-Line Canada offers an extensive range of conduit and innerduct solutions to meet the diverse needs of customers. They have the capacity to extrude over 20 different conduit types including PVC, HDPE and fiber duct. These offerings cater to various applications such as telecommunications, power, utilities, and transportation.

Innovation and Technological Advancements:

Dura-Line Canada is at the forefront of innovation in conduit solutions. They invest in research and development to introduce advanced technologies that enhance the performance and efficiency of their products. For example, their MicroTechnology™ solutions provide compact and flexible pathways for fiber optic cables, enabling faster and easier installations.

Superior Durability and Protection:

Dura-Line Canada’s conduits are engineered to provide outstanding durability and protection for sensitive cables and fibers. Their HDPE conduit offers exceptional resistance to impact, environmental stress, and harsh weather conditions. This ensures long-term reliability and minimizes the risk of damage to critical infrastructure.

Commitment to Quality and Compliance:

Dura-Line Canada maintains a strong commitment to quality and compliance with industry standards. Their conduit solutions meet or exceed the necessary requirements, including the National Electrical Code (NEC), Canadian Electrical Code (CEC),CSA, ULC and NEMA. By adhering to these rigorous standards, Dura-Line Canada ensures that their products deliver reliable performance and comply with safety regulations.

Strong Industry Presence and Global Reach:

Dura-Line Canada is part of Dura-Line, a global leader in conduit solutions. This affiliation provides Dura-Line Canada with access to industry-leading expertise, resources, and advanced manufacturing capabilities. It allows them to deliver high-quality products and services that meet the evolving needs of customers in Canada and beyond.

Thomas & Betts (ABB)

Thomas & Betts (ABB), is a renowned global provider of electrical and power management solutions. With a rich history dating back to 1898, Thomas & Betts has established itself as a trusted name in the industry.

Comprehensive Product Portfolio:

Thomas & Betts (ABB) offers a comprehensive range of electrical and power management solutions. Their product portfolio includes electrical conduit, connectors, fittings, cable management systems, enclosures, and control panels. These products cater to various industries, including residential, commercial, industrial, and utility sectors.

Technological Advancements and Innovation:

Thomas & Betts (ABB) is committed to technological advancements and innovation. They invest in research and development to introduce cutting-edge solutions that improve electrical safety, efficiency, and performance. Their smart technologies incorporate connectivity, automation, and energy management features, enabling enhanced functionality and control.

ABB Ability™:

Thomas & Betts (ABB) harnesses the power of ABB Ability™, a comprehensive digital offering by ABB. ABB Ability™ integrates advanced technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) to enable digitalization and connectivity. It allows for real-time monitoring, data analysis, and automation, facilitating improved operational efficiency and decision-making.

Quality and Compliance:

Thomas & Betts (ABB) places a strong emphasis on delivering products of exceptional quality and ensuring compliance with industry standards. The company adheres to stringent manufacturing standards and undergoes rigorous testing to ensure durability and performance. They hold certifications such as ISO 9001 for quality management systems and specific product safety certifications like UL and CSA.

Global Presence and Expertise:

As part of ABB, Thomas & Betts benefits from a global presence and extensive expertise in the electrical industry. Their global network of manufacturing facilities, research centers, and service centers enables them to provide localized support and solutions to customers worldwide. This ensures efficient delivery and support for customers across different regions.

Energy Efficiency and Sustainability:

Thomas & Betts (ABB) recognizes the importance of energy efficiency and sustainability. They offer solutions that help customers optimize energy usage, reduce environmental impact, and meet sustainability goals. From energy management systems to eco-friendly materials, Thomas & Betts (ABB) strives to promote sustainable practices throughout their operations.

Cantex Inc.

CANTEX is a leading manufacturer of PVC electrical conduit and fittings. With a history of over 70 years, Cantex Inc began as a division of Texas-Vitrified, serving the utility and building construction industry. As the plastics division grew, Cantex expanded into various categories of PVC products. In the 90s, Cantex narrowed its focus to PVC electrical and communications products, catering to the demands of a highly technical era. Today, Cantex is recognized as a leading producer of American-made PVC electrical conduit and fittings.

Product Range:

Cantex offers a comprehensive range of PVC electrical products designed to meet diverse needs. These include schedule 40 and 80 pipe/conduit, utility-grade Forte-Duct cellular foam core conduit and duct, molded and fabricated PVC electrical fittings and accessories, specialized conduit systems like Can>Loc and Can>Grip for directional drilling or trenchless raceway applications, utility ducts, telephone conduit types, utility and communication duct fittings, elbows, bends, sweeps, nonmetallic flexible tubing and fittings, liquidtight conduit and fittings, switch, outlet, and ceiling boxes, cements, and wildlife protectors.

Manufacturing and Distribution Facilities:

Cantex has strategically placed manufacturing and distribution facilities nationwide. These facilities are equipped with modern production equipment and utilize advanced process technology. The company’s commitment to technological advancements ensures the production of high-quality PVC products.

Industry Applications:

Cantex’s PVC electrical conduit, fittings, and accessories, along with their other product lines, cater to a wide range of industry applications. These include power, utility, building construction, and communications markets worldwide. Cantex’s products are designed to provide reliable and durable solutions to keep people powered and connected.

Focus on Customer Service:

Cantex is dedicated to exceptional service, aiming to provide electrical distributors, contractors, and end users with superior PVC electrical products. The company’s commitment to customer satisfaction is demonstrated through its broad product line, technical expertise, and support.

Customization Options:

Cantex understands the importance of meeting unique project requirements. They offer custom sizes for special radius sweeps and elbows upon request. This customization option ensures that customers can obtain tailored solutions for their specific needs.

Zekelman Industries (Wheatland Tube)

Zekelman Industries is one of the largest independent steel pipe and tube manufacturers in North America. Its subsidiary, Wheatland Tube, has a rich history dating back to 1877 and is known for its commitment to delivering high-quality products and exceptional customer service. With a strong commitment to excellence, Zekelman Industries (Wheatland Tube) has established itself as a trusted provider of steel pipe and tube solutions.

Steel Conduit Expertise:

Wheatland Tube, under Zekelman Industries, is renowned for its expertise in steel conduit. The company offers a wide range of steel conduit products, including rigid steel conduit (RMC), intermediate metal conduit (IMC), and electrical metallic tubing (EMT). These conduits provide durable and reliable protection for electrical wiring systems in various applications.

Comprehensive Product Line:

In addition to steel conduit, Zekelman Industries (Wheatland Tube) manufactures a diverse range of other steel pipe and tube products. This includes standard pipe for plumbing and industrial applications, mechanical tube for precision engineering, and fence framework for residential, commercial, and industrial fencing projects. Their comprehensive product line caters to a variety of industries and applications.

Manufacturing Excellence:

Zekelman Industries (Wheatland Tube) operates advanced manufacturing facilities equipped with state-of-the-art machinery and technology. The company utilizes modern production processes, such as continuous electric resistance welding (ERW) and high-frequency induction (HFI) welding, to ensure consistent quality and precision in their steel pipe and tube manufacturing.

Quality and Certifications:

Wheatland Tube is committed to producing products that meet and exceed industry standards. The company adheres to rigorous quality control processes throughout its manufacturing operations. Wheatland Tube’s products are manufactured in accordance with various specifications and certifications, including ASTM, UL (Underwriters Laboratories), FM (Factory Mutual), and CSA (Canadian Standards Association).

Customer Support and Service:

Zekelman Industries (Wheatland Tube) places a strong emphasis on customer support and service. The company has a dedicated team of experts who provide technical assistance, guidance, and solutions to customers. Wheatland Tube is known for its responsive communication, timely delivery, and reliable after-sales support, ensuring customer satisfaction.

Allied Tube & Conduit

Allied Tube & Conduit is recognized as one of the top electrical conduit manufacturers in Canada. With a strong presence and a reputation for excellence, the company has been providing high-quality electrical conduit solutions for various industries and applications in the Canadian market.

Extensive Product Range:

Allied Tube & Conduit offers an extensive range of electrical conduit products to meet the diverse needs of the Canadian market. Some of their key offerings include:

- Rigid Steel Conduit (RMC): RMC is a robust and durable conduit solution used to protect electrical wiring in commercial, industrial, and residential applications. Allied Tube & Conduit produces RMC that meets Canadian standards and specifications.

- Intermediate Metal Conduit (IMC): IMC is a lighter-weight alternative to RMC while providing similar protection. It is commonly used in applications where flexibility and ease of installation are important factors.

- Electrical Metallic Tubing (EMT): EMT is a lightweight and cost-effective conduit option suitable for both exposed and concealed electrical installations. Allied Tube & Conduit manufactures EMT that complies with Canadian standards.

Manufacturing Excellence:

Allied Tube & Conduit maintains advanced manufacturing facilities equipped with cutting-edge technology and machinery. Their state-of-the-art production processes ensure precise manufacturing and consistent quality in their electrical conduit products. The company utilizes modern techniques such as electric resistance welding (ERW) to deliver reliable and high-performance conduits.

Compliance with Canadian Standards:

Allied Tube & Conduit places a strong emphasis on meeting Canadian standards and specifications. Their electrical conduit products are manufactured in compliance with the requirements set by regulatory bodies and industry organizations in Canada. This ensures that their products meet the necessary safety and performance standards for electrical installations in the country.

Sustainability Initiatives:

Allied Tube & Conduit recognizes the importance of sustainability and environmentally responsible practices. They strive to minimize their environmental impact by implementing sustainable manufacturing processes and utilizing recycled materials wherever possible. Their commitment to sustainability aligns with the increasing demand for eco-friendly products.

National Pipe & Plastics

National Pipe & Plastics is recognized as one of the top electrical conduit manufacturers in Canada. With a strong presence and a reputation for excellence, the company has been providing high-quality electrical conduit solutions for various industries and applications in the Canadian market.

Extensive Product Range:

NPP offers an extensive range of electrical conduit products to meet the diverse needs of the Canadian market. Some of their key offerings include:

- PVC Conduit: NPP manufactures PVC (polyvinyl chloride) conduit, which is widely used for electrical wiring and cable management. PVC conduit is known for its durability, corrosion resistance, and ease of installation. NPP produces PVC conduit that meets Canadian standards and specifications.

- HDPE Conduit: High-density polyethylene (HDPE) conduit is another popular product offered by NPP. HDPE conduit is known for its strength, flexibility, and resistance to chemicals. It is commonly used in applications where extra protection and durability are required.

Manufacturing Excellence:

NPP operates state-of-the-art manufacturing facilities equipped with advanced technology and machinery. The company employs extrusion techniques to ensure precise manufacturing and consistent quality in their electrical conduit production. NPP’s manufacturing processes prioritize quality control and adherence to rigorous industry standards.

Compliance with Canadian Standards:

NPP places a strong emphasis on meeting Canadian standards and specifications. Their electrical conduit products are manufactured in compliance with the requirements set by regulatory bodies and industry organizations in Canada. This ensures that their products meet the necessary safety and performance standards for electrical installations in the country.

Customization and Innovation:

NPP understands the importance of customization and innovation to meet unique customer requirements. They offer a range of customization options, including various sizes, lengths, and fittings. The company also invests in research and development to drive product innovation and stay at the forefront of the electrical conduit industry.

Westlake Pipe

Westlake Pipe, a division of the renowned Westlake Corporation, stands out as a leading manufacturer of high-quality PVC (Polyvinyl Chloride) conduit pipes, catering to the Canadian market and beyond. With a commitment to innovation and quality, Westlake Pipe offers a comprehensive range of electrical conduits and fittings that are designed to protect and manage electrical wiring in commercial, industrial, and residential settings.

Their PVC conduit pipes and fittgins are known for their durability, ease of installation, and excellent resistance to chemicals and environmental conditions. These pipes meet stringent safety and performance standards, such as UL 651, CSA C22.2 No.227.1, Certified CSA C22.2 No. 211.1, ensuring reliability and safety in every installation.

Westlake Pipe’s products are not only cost-effective but also contribute to sustainable building practices due to the low maintenance requirements and long lifespan of PVC materials. Whether it’s rigid conduit for structural integrity or flexible conduit for complex routing needs, Westlake Pipe provides solutions tailored to diverse electrical applications.

For professionals seeking dependable electrical conduit systems, Westlake Pipe offers a trusted choice backed by the reputation of Westlake Corporation, a global leader in plastics and building materials.

Ctube

Ctube is an emerging company in the Canadian market that specializes in the manufacturing of electrical PVC conduit. With innovative technology and a commitment to high-quality products, Ctube has gained recognition and appreciation from an increasing number of customers in the local market.

Product Excellence:

Ctube focuses on electrical conduit’s research and development, provides a versatile and widely used solution for cable management and protection in various electrical installations. Their PVC conduit is known for its durability, flexibility, and ease of installation. It provides reliable performance and safeguards electrical wiring in commercial, industrial, and residential applications.

Innovative Technology:

Ctube differentiates itself through its innovative technology, which allows them to deliver advanced solutions in the electrical PVC conduit industry. By adopting cutting-edge manufacturing processes and equipment, Ctube ensures the production of high-quality conduit that meets industry standards and customer expectations.

High-Quality Products:

Ctube is committed to delivering products of the highest quality. They adhere to stringent quality control measures throughout the manufacturing process to ensure that their electrical PVC conduit meets or exceeds industry standards. Products certified by CSA, UL, CE, IEC and ASTM etc. By prioritizing quality, Ctube aims to provide customers with reliable and long-lasting conduit solutions.

Customer Focus:

Ctube places a strong emphasis on customer satisfaction and seeks to understand and meet the unique needs of their clients. They strive to provide excellent customer service, offering technical support, guidance, and tailored solutions to help customers choose the right electrical PVC conduit for their specific applications.

Sustainable Practices:

Ctube recognizes the importance of sustainable manufacturing practices. They prioritize the use of environmentally friendly materials and implement sustainable processes to reduce waste and minimize their environmental impact. By providing eco-friendly electrical PVC conduit solutions, Ctube demonstrates their commitment to sustainability.

结论

Overall, when considering the top electrical conduit manufacturers and suppliers in Canada, it is essential to evaluate several factors to make an informed choice that aligns with your project requirements. Quality should be a top consideration, ensuring that the manufacturer produces reliable and durable conduit solutions. Assessing the range of product models available allows you to select the most suitable conduit for your specific applications. It is also important to consider the intended usage of the conduit, ensuring it meets the necessary standards and specifications for your project.

Price is another significant factor to consider, as it impacts your project budget. Comparing the pricing structures of different manufacturers will help you find a balance between cost-effectiveness and quality. Additionally, considering factors such as the manufacturer’s reputation, customer reviews, and industry certifications can provide valuable insights into their reliability and customer satisfaction.

Ultimately, selecting the right electrical conduit manufacturer involves a comprehensive evaluation of various aspects, including quality, product models, intended usage, and pricing. By conducting thorough research and considering these factors, you can make an informed decision that meets your project needs and ensures the successful implementation of your electrical conduit systems.

Related Topic : Top 10 PVC Conduit Manufacturers and Suppliers in Canada

Top 10 Electrical Conduit Manufacturers and Suppliers in Canada 阅读更多 "