How to Choose the Conduit Size for Electrical Installations

Introduction

Having a thorough understanding of conduit size is paramount. In order to ensure proper insulation and prevent damage, conduits are essential for organizing and protecting electrical wire. For your electrical system to operate safely and effectively, choosing the right conduit size is crucial.

We shall explore all of the factors that need to be taken into account in order to choose the right conduit size in this article. In addition, we will provide you with an extensive mathematical technique in order to support informed decision-making. Moreover, we will spotlight several prevalent conduit sizes to enhance your comprehension of the array of options. Let us commence our exploration!

Mastering the Basics of Conduit Size

Prior to delving into the various factors that influence conduit size selection, it is crucial to comprehend conduit size itself. Conduit size is the measurement of the inner diameter of a conduit that serves as a path for electrical wires or cables. Care must be taken while choosing the size of the conduit to allow for future additions or changes and to ensure that the wires may pass through freely without being compressed or interfered with.

The most common diameters for conduits are 1/2 inch to 6 inches, and sizes are typically stated in inches. Larger sizes can also be ordered for particular commercial and industrial applications. Conduit size selection is influenced by various elements, including the kind and quantity of installed wiring.

It is important to keep in mind that conduit and wire sizes are not usually the same. The National Electrical Code (NEC) establishes the maximum number of wires or cables that can be safely placed inside a conduit, depending on the size and type of insulation. By following these guidelines, you can be sure that the wires will have the space to release heat and prevent overheating, which could pose a fire risk.

Now that we have a rudimentary understanding of conduit size, let us look at the factors to take into account when selecting the appropriate size for your electrical installation.

Critical Considerations When Determining Conduit Size

Several important criteria need to be taken into account when choosing the right conduit size for your electrical installation in order to guarantee future-proofing, safety, and compliance.

The Number of Wires

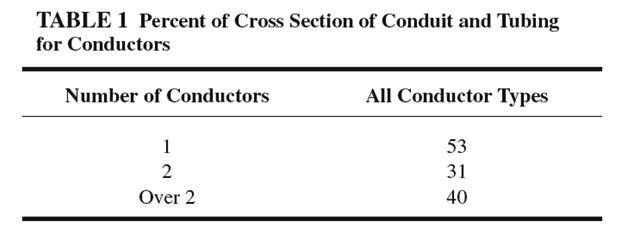

How many wires or cables will be routed via a conduit is one of the main factors affecting its size. For the purpose of preventing crowding and guaranteeing enough airflow for heat dissipation, the National Electrical Code (NEC) offers comprehensive standards on the maximum fill capacity of conduits. These rules are essential because clogged conduits can overheat and cause a serious fire hazard. The percentage fill for different conduit sizes and kinds is specified by the NEC. For example, the conduit fill should not be more than 53% of its capacity when it comes to a single wire, 31% when it comes to two wires, and 40% when it comes to three or more wires. These recommendations must be followed in order to calculate the appropriate conduit size based on the number and size of wires you plan to install.

The Type and Size of Wires

There are specifications for fill capacity and spacing for various insulation kinds and wire sizes, which are specified in American Wire Gauge (AWG). There are fewer cables that can fit safely inside a conduit because, for instance, heavier or thicker wires need more room. Moreover, the conduit size required to ensure safe operating conditions may vary depending on the wire type and its rating for certain temperature thresholds. Make sure you know the specs for the wires you are utilizing, and choose a conduit size that satisfies these needs.

Bend Radius

The bend radius is the smallest radius that allows a conduit to be bent securely without endangering the internal wiring. This is especially crucial for installations that have a lot of curves or small spaces. If a conduit is too narrow, it could not be able to accommodate the required bend radius, which could result in kinks or abrupt bends that could harm the insulation or the wires themselves and possibly cause shorts or service outages. The NEC specifies minimum bend radius requirements for various conduit and cable types, guaranteeing that wire integrity is upheld throughout installation.

Future Expansion

When planning your electrical installation, it is prudent to consider future expansions or modifications. Selecting a slightly larger conduit than currently required can provide room for additional wires or cables that may be needed in the future. This forward-thinking approach can save considerable time and expense, as it avoids the need for replacing conduits or undertaking significant rewiring projects to accommodate additional circuits. By planning for potential growth, you can ensure that your electrical system remains adaptable and efficient.

Environmental Factors

Environmental conditions play a significant role in determining the appropriate conduit size and type. Installations exposed to extreme temperatures, moisture, chemicals, or corrosive substances may require conduits made of materials resistant to these conditions, such as PVC or stainless steel. Additionally, conduits in outdoor or hazardous locations may need to be larger to accommodate additional insulation or protective coatings that shield the wires from environmental stressors. Ensuring that the conduit material and size are suited to the installation environment is crucial for maintaining system integrity and safety.

Additional Considerations

Beyond the primary factors listed, several additional considerations can influence conduit sizing:

1. Conduit Material: Different materials such as metal (EMT, IMC, RMC) or non-metallic (PVC, HDPE) conduits have different internal diameters and bend radii, impacting the fill capacity and ease of installation.

2. Voltage Drop: For long conduit runs, voltage drop can be a concern. Larger conduits may be needed to accommodate thicker wires that mitigate voltage drop over distance.

3. Accessibility: Future maintenance or upgrades are easier with conduits that provide ample space for pulling and replacing wires.

4. Local Codes and Regulations: Always check local building codes and regulations, as they may have additional requirements or restrictions beyond the NEC standards.

By considering these factors—number of wires, type and size of wires, bend radius, future expansion, environmental factors, and additional considerations—you can ensure that your electrical installation is safe, efficient, and adaptable to future needs. Proper conduit sizing not only enhances the longevity and reliability of your electrical system but also ensures compliance with regulatory standards, ultimately safeguarding both property and occupants.

Step-by-Step Guide to Calculating Conduit Size

Calculating the correct conduit size for your electrical installation involves a systematic approach that ensures safety, compliance with standards, and future-proofing. Here’s a comprehensive step-by-step guide on how to calculate the appropriate conduit size:

1. Determine the Total Area Required for the Wires

Identify Wire Sizes and Types: Start by listing all the wires that will run through the conduit, including their sizes (in American Wire Gauge, AWG) and insulation types.

Calculate Individual Wire Areas: Using the NEC wire fill tables, find the cross-sectional area for each wire. These tables provide the areas in square inches for different wire sizes and insulation types.

Sum the Wire Areas: Add up the cross-sectional areas of all the wires that will be placed in the conduit. This sum represents the total area required for the wires.

2. Measure the Cross-Sectional Area of the Conduit

Select Conduit Type: Determine the type of conduit (e.g., Electrical Metallic Tubing (EMT), Polyvinyl Chloride (PVC), or Rigid Metal Conduit (RMC)). Different conduit types have varying internal diameters even for the same nominal size.

Measure or Look Up the Internal Diameter: For precise calculations, use the actual internal diameter of the conduit, which can be found in manufacturer specifications or NEC tables.

Calculate Cross-Sectional Area: Use the formula , where A is the cross-sectional area and r is the radius of the conduit. The radius is half of the internal diameter. For example, if the internal diameter is 1 inch, the radius is 0.5 inches, and the area A is 3.1416 × (0.5)2 = 0.785 square inches.

3. Multiply the Cross-Sectional Area by the Conduit Fill Ratio

Determine the Conduit Fill Ratio: The NEC provides fill ratios based on the number of wires in the conduit. Typically, the ratios are:

– 53% for a single wire.

– 31% for two wires.

– 40% for three or more wires.

Calculate the Maximum Fill Area: Multiply the conduit’s cross-sectional area by the appropriate fill ratio. For instance, if the conduit area is 0.785 square inches and the fill ratio for three wires is 40%, the maximum fill area is 0.785 × 0.40 = 0.314 square inches.

4. Compare the Maximum Fill Area with the Total Area Required

Evaluate Sufficiency: Compare the calculated maximum fill area of the conduit with the total area required for the wires.

– If the maximum fill area is equal to or greater than the total area required, the conduit size is sufficient.

– If the maximum fill area is less than the total area required, you will need to select a larger conduit size.

Common Conduit Sizes and Their Applications

There are several standard conduit sizes ranging from 1/2 inch to 8 inches, commonly used in residential, commercial, and industrial electrical installations. Here are some of the most frequently utilized conduit sizes:

1/2 Inch Conduit

Smallest Conduit Size: This is the smallest standard conduit size and is typically used for individual branch circuits or applications requiring only a few wires. It’s ideal for light residential use, such as wiring for lighting and small appliances.

3/4 Inch Conduit

Residential Use: The 3/4 inch conduit is a popular choice in residential settings. It is suitable for running multiple wires or cables within a single conduit, making it ideal for standard household circuits and smaller commercial applications.

1 Inch Conduit

Commercial and Larger Residential Installations: The 1 inch conduit size is often used in commercial environments and larger residential installations. It can accommodate a greater number of wires and is suitable for main service panels, subpanels, and other applications requiring more extensive wiring.

1-1/4 Inch Conduit

High Voltage and Commercial Applications: This size is commonly used for higher voltage circuits and commercial installations where larger wires or cables need to be routed. It’s also suitable for feeder circuits in large residential buildings or small commercial establishments.

1-1/2 Inch Conduit

Larger Commercial and Industrial Installations: The 1-1/2 inch conduit is designed for substantial commercial and industrial applications where a significant amount of wiring is needed. It provides ample space for larger cable bundles, making it suitable for complex wiring systems.

Additional Sizes (e.g., 2inches, 3 inches, 4 inches, 5 inches, 6 inches, 7 inches, 8 inches)

Industrial and Heavy-Duty Applications: Conduit sizes of 2 inches and above are typically reserved for industrial settings or heavy-duty applications. These larger conduits are essential for housing large bundles of wires or cables, such as those used in manufacturing facilities, data centers, and large commercial buildings. They provide the necessary capacity for extensive electrical systems and ensure ease of installation and maintenance.

结论

For electrical installations to be safe and effective, choosing the right conduit size is essential. The method necessitates a thorough comprehension of a number of crucial elements, such as the quantity and kind of wires, the bend radius, requirements for future extension, and environmental considerations. In addition to making maintenance simpler and ensuring compliance with National Electrical Code (NEC) regulations, proper conduit sizing also helps prevent overheating.

By employing a methodical methodology to determine the conduit size, you can guarantee that your wiring is sufficiently safeguarded and functions inside safe bounds. To do this, measure the cross-sectional area of the conduit, apply the appropriate fill ratio, and compare the resultant area to the total area needed for the wires. Understanding these calculations and the impact of each factor allows you to make informed decisions.

The most used conduit sizes are 1/2 inch to 8 inches, with each fitting a specific purpose ranging from modest home use to demanding industrial requirements. Future expansion-capable conduit selection can save money and time by minimizing the need for pricey replacements or upgrades.

In conclusion, a sturdy and flexible electrical system is ensured by careful consideration of conduit size. You may improve the safety, effectiveness, and longevity of your installations by following NEC requirements and taking a number of aspects into consideration. In addition to satisfying present demands, appropriate conduit sizing helps to future-proof your electrical infrastructure by making sure it can withstand expansion and demand variations.

How to Choose the Conduit Size for Electrical Installations 阅读更多 "